Frame and suspensions

CHASSIS AND SUSPENSIONS

Specification Desc./Quantity

Chassis diagonal twin spar frame.

Front suspension: Hydraulic fork and centred axle.

Rear suspension: Swinging with hydraulic progressive shock absorber.

Brakes

BRAKES

Specification Desc./Quantity

Front wheel brake: Hydraulic disc

Ø 240 mm (RCR)

Ø 260 mm (SMT)

Rear wheel brake: Hydraulic Ø 180 mm disc.

Wheels and tyres

WHEELS AND TYRES

Specification Desc./Quantity

Front tyre: 80/90 x 21'' (RCR)

100/80 x 17'' (SMT)

Rear tyre: 110/80 x 18'' (RCR)

130/70 x 17'' (SMT)

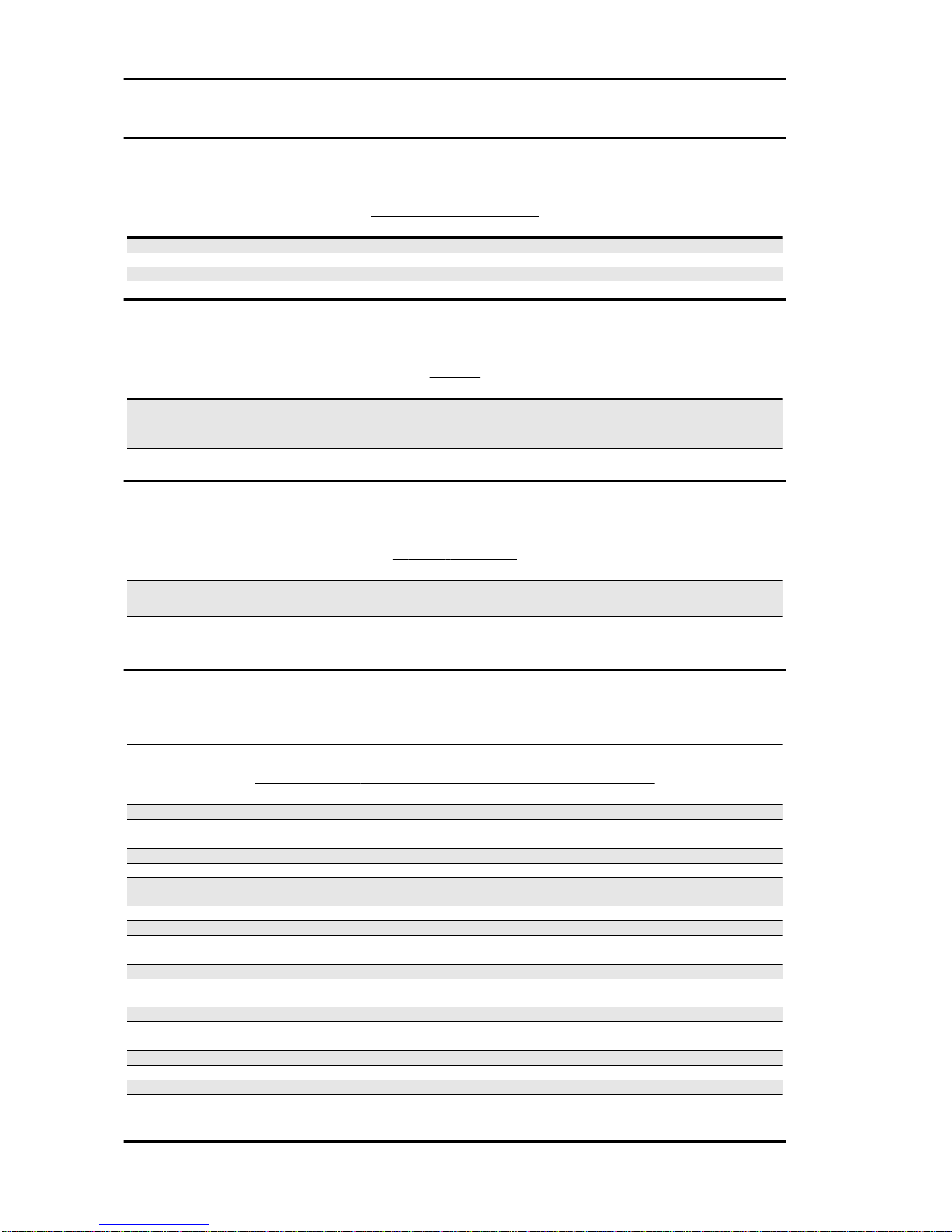

Tightening Torques

Standard tightening torques

TORQUE IN NMBY TYPE OF TIGHTENED MATERIAL

Name Torque in Nm

M4 Ø 8.8 steel screw on plastic with metallic spacers 2

M4 Ø 8.8 steel screw on brass, copper, aluminium and their

alloys 2

M4 Ø 8.8 steel screw Iron, steel 3

M5 Ø 8.8 steel screw on plastic with metallic spacers 4

M5 Ø 8.8 steel screw on brass, copper, aluminium and their

alloys 4

M5 Ø 8.8 steel screw Iron, steel 6

M6 Ø 8.8 steel screw on plastic with metallic spacers 6.5

M6 Ø 8.8 steel screw on brass, copper, aluminium and their

alloys 6.5

M6 Ø 8.8 steel screw Iron, steel 10.5

M7 Ø 8.8 steel screw on brass, copper, aluminium and their

alloys 10.5

M7 Ø 8.8 steel screw Iron, steel 17

M8 Ø 8.8 steel screw on brass, copper, aluminium and their

alloys 16

M8 Ø 8.8 steel screw Iron, steel 26

M10 Ø 8.8 steel screw Iron, steel 52

M12 Ø 8.8 steel screw Iron, steel 100

M14 Ø 8.8 steel screw Iron, steel 145

Characteristics SMT RCR

CHAR - 10