3

Indice

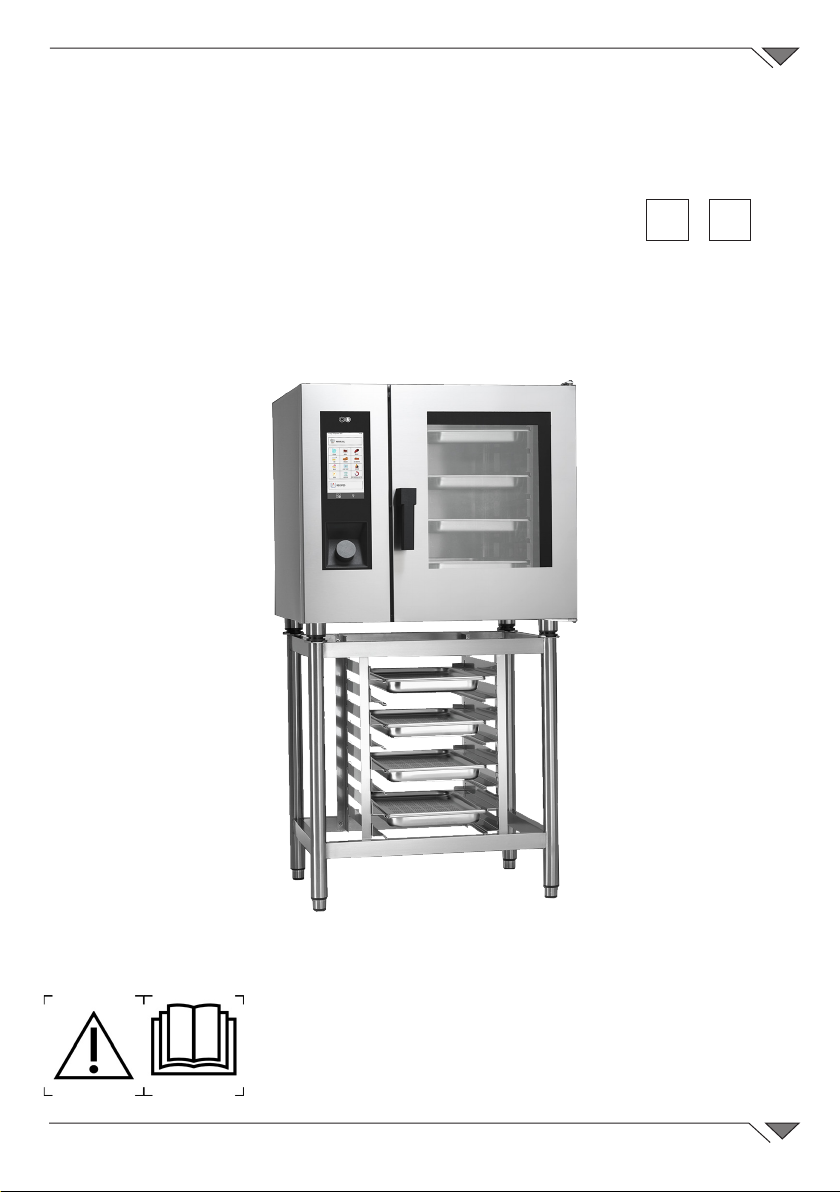

1. INSTALLATION 5

1.1 General and safety warnings �����������������������������������������������5

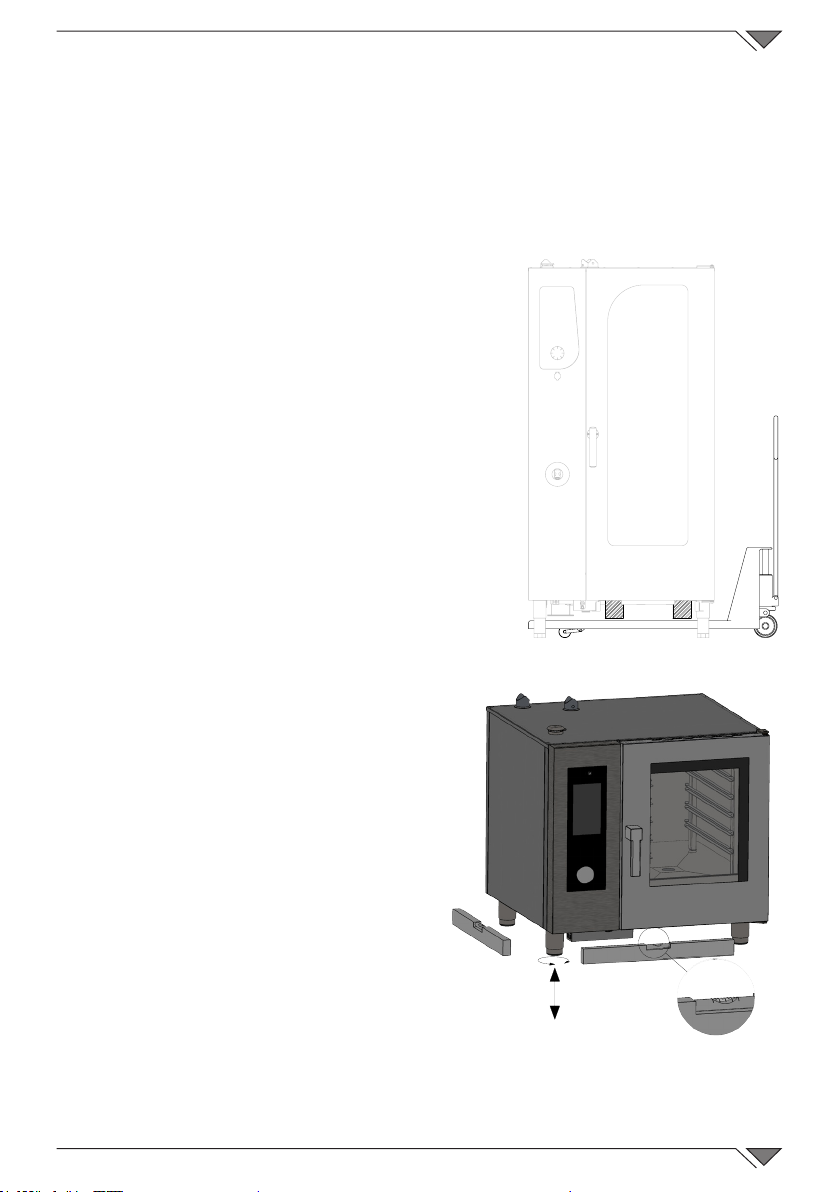

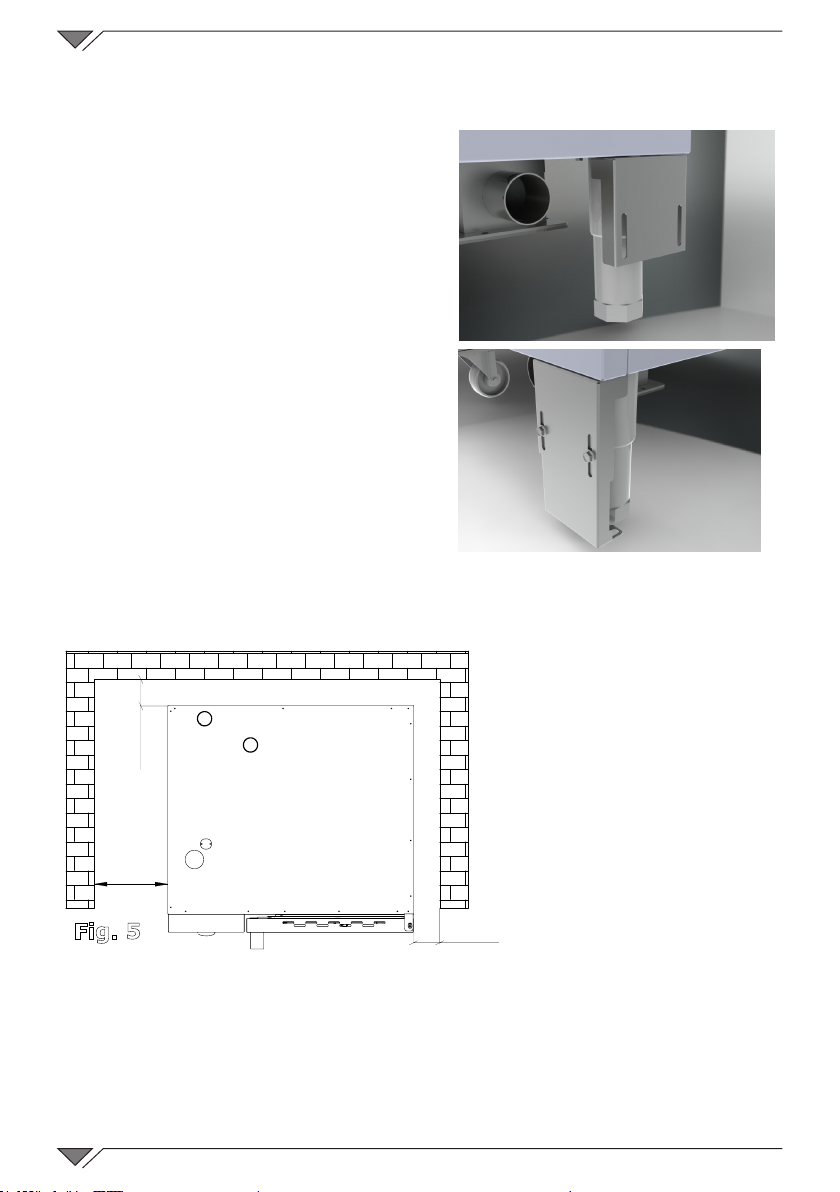

1.2 Positioning ��������������������������������������������������������������������������9

1.3 Water connection ��������������������������������������������������������������11

1.4 Connection to the drain �����������������������������������������������������11

1.5 Connection to detergent and rinse ������������������������������������12

1.6 Electric connection ������������������������������������������������������������12

1.7 Connecting the gas (gas ovens only) ��������������������������������14

1.8 Smoke exhaust ������������������������������������������������������������������15

1.9 Gas oven operating values (for gas versions only)��������������16

1.10 Adjusting the hinges and the closing pin on the door �������������17

1.11 Oven commissioning and testing ������������������������������������18

2. COOKING 20

2.1 Pictograms key �����������������������������������������������������������������20

2.2 Home Screen ��������������������������������������������������������������������22

2.3 How to interact with the touch-screen ������������������������������22

2.4 Manual cooking mode �������������������������������������������������������23

2.4a Cooking modes: convection, mixed and steam �����������������24

2.4b HOLD Mode ����������������������������������������������������������������������26

2.4c Smoking mode ����������������������������������������������������������������26

2.4d Messagge mode ���������������������������������������������������������������27

2.4d Starting and stopping cooking �����������������������������������������28

2.5 Customised cooking programs �������������������������������������������28

2.6 Creating a cooking program�����������������������������������������������29

2.7 Saving a cooking program������������������������������������������������ 30

2.8 Modifying a cooking program���������������������������������������������32

2.9 Copy, move, rename and delete �����������������������������������������32

2.10 Selecting a program from the menu���������������������������������33

2.11 The RecipeTuner interfaces����������������������������������������������34

2.12 Rack Control service mode�����������������������������������������������35

2.12a Using the Rack Control function �������������������������������������36

2.12b Creating a new RackControl program�����������������������������39

2.13 Using the EasyService function in RackControl����������������40

2.14 The scheduled departure��������������������������������������������������������������������� 41

2.15 The Regeneration function ������������������������������������������������������������41

2.15a Regeneration Programs �������������������������������������������������42

2.16 The core probe and cooking in ΔT �����������������������������������43

2.17 Recommendations for cooking: roasting, grilling and frying ������������������44

2.17a Cooking advice: cooking uniformity ������������������������������44