13 | Page

NOTE: Please consult your RV’s wiring diagram to ensure that no wiring will be

damaged while drilling the hole.

A. SIDEWALL APPLICATION

NOTE: Please take into consideration all possible clearances, and obstacles before

installing this awning. Items such as slide rooms, etc. vary from one manufacturer to

another. Please consult Girard Systems if there are any questions regarding your

installation.

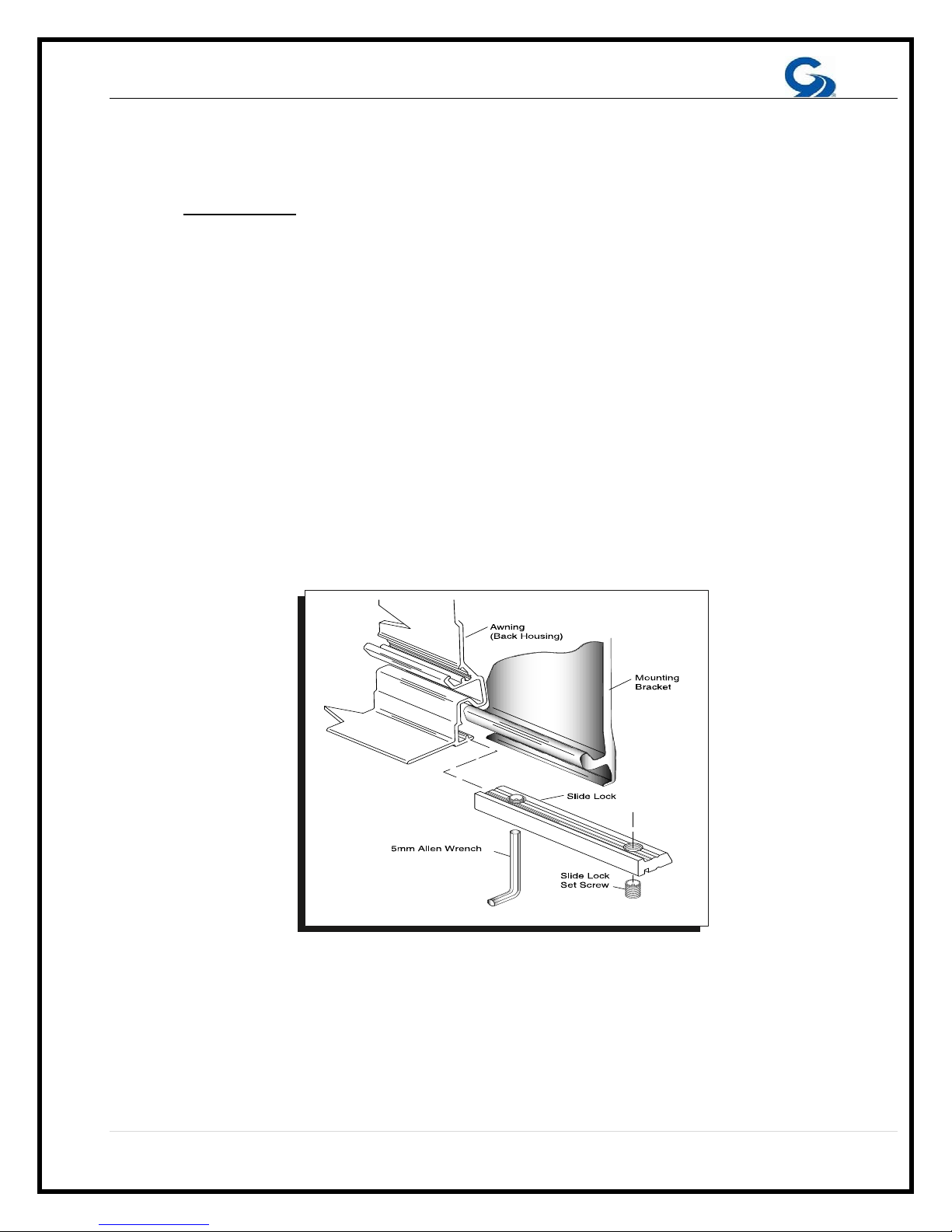

1. The mounting brackets and hardware used for this application are included with

your awning.

2. Determine the location for the final installation position of the awning, including

height to be installed.

3. Mounting brackets must be installed within two (2) inches of the ends of the

awning. Once you have determined the location of the two end brackets snap a

chalk line between the two points to ensure straightness of the installation. You

will be able to use this reference line to install the smaller center bracket at a

later time.

4. To find the location of the smaller center bracket please refer to chart on the

following page. NOTE: The location of the center bracket must fall directly

centered behind the center shoulder location. Failure to follow these

instructions will void the warranty of this product.

5. Now that you have located the bracket locations, using the bracket as your

template, mark the holes for fastening the bracket.

6. Using a 1/8” bit (8” long), pilot drill the centers of the marked holes. Inside of the

RV verify the locations of the backing plates. NOTE: Please consult your RV’s

wiring diagram to ensure that no wiring will be damaged while drilling the

hole.

7. Pre-drill six 7/16” holes per mounting bracket through the pilot holes.

8. Apply a liberal amount of silicone caulking around each hole before installing the

brackets.

9. Install the two (2) outer brackets, and then the center bracket (if required) with six

7/16” carriage bolts, washers, nylon nuts and two(2) backing plates per bracket.

(Figure 3) Tighten bolts and then apply silicone caulking to the top edge and both

sides of each bracket.

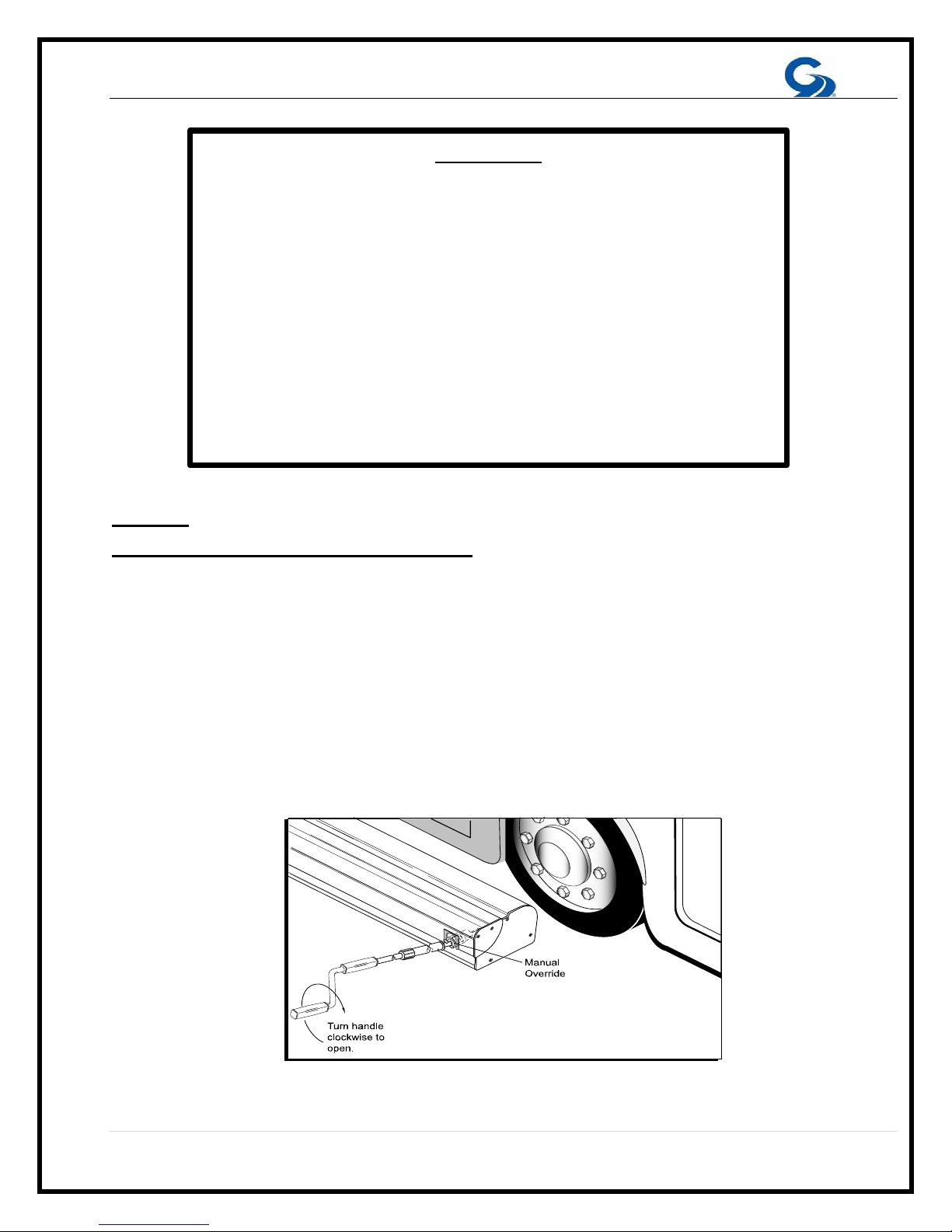

10.On the motor side of the awning drill a 7/16” hole for the awning motor cable to

enter the RV near the electrical source. Position the hole 1” to the left or right of

the bracket depending on motor location. Do not drill hole higher or lower than

the bracket. This will ensure that it will not be seen after the awning is installed.