W

et Air Cutting S w GPW-227

ble of Contents

1

GISON

T ble of Contents

Import nt S fety Instruction

Read all instructions before using this tool. All

operators must be fully trained in its use and

aware of safety rules.

1) M inten nce

Oil 3cc lubricant (SAE #10 or equiv lence)

through air inlet before connecting the

product to the air. Run the tool 15 seconds

to allow air circulating the oil and well

lubricate the cylinder. This will ensure top

performance and maximize durability of tool.

Oil 3cc lubricant through air inlet after use

and run the tool 5 seconds before storage.

Clear dry air allows the product perform at

its best and extends the product life. A Filter/

Regulator/Lubricator set is highly

recommended.

If the tool is in unusual condition, shut it off

and disconnect its air hose immediately. Put

a warning sign on the product until it gets

repaired.

Product repairing needs professional training

and tool. Do not attempt to disassemble the

product or it might be damaged.

2) User

The user must be well trained and physically

able to operate the product and aware of

safety regulation.

Use personal safety equipment such as

goggle, earmuffs, mask apron.

Maintain a balanced body position and

secure distance. Do not wear jewelry or

loose clothing. Helmet is required if you wear

long hair.

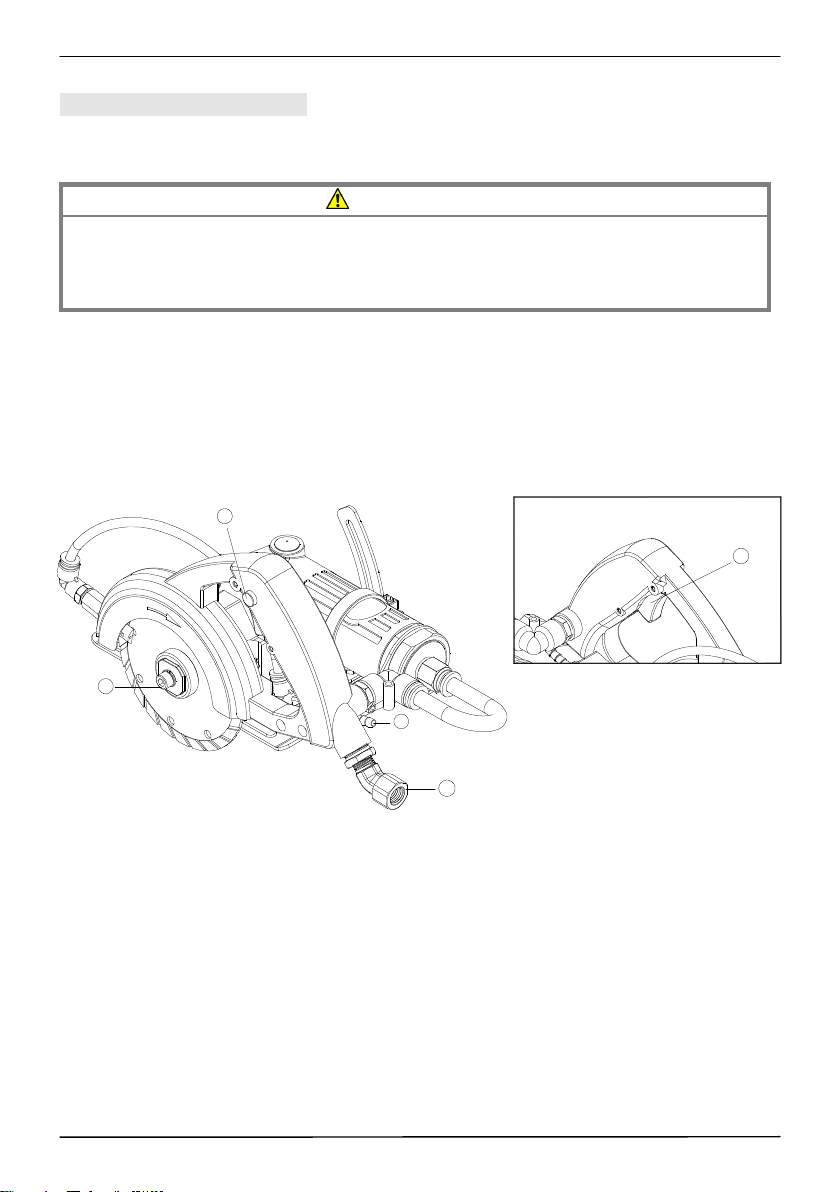

3) Compressed Air

Do not operate the product with excess air

pressure; standard air pressure is 90 psi (6.2

bar or 6.3kg/cm2).

Always shut off air supply, drain hose of air

pressure and disconnect product from air

supply before changing accessories, making

repairs or when the tool is not in use.

Never direct air or product at yourself or

anyone else.

Whipping hose can be extremely dangerous

and causes serious injury. Always check for

damaged or loose hoses and fittings.

4) Product

Do not adapt the product for other purpose; it

might harm the product and the user.

Do not adapt or remove the switch, level or

any other component of the product; it might

result in malfunctioning and harm the user.

Do not use quick connect coupling on the

product directly; use it only on the hose end.

The product is not insulator; keep away from

electricity.

5) Accessories

Please use proper accessories, improper or

unqualified accessories may damage the

product, deteriorate performance and do

harm to user.

When replacing the accessories, use the tool

attached with the product. Improper tool or

incorrect ways of handling the tool (such as

strike) may damage it.

6) Workpl ce

Slip, trip fall are major causes of serious

injury or death; be aware of excess hose left

on the walking or working surface.

Workpiece must be fixed firmly; always keep

no miscellaneous objects that could interfere

with the operation.

Import nt S fety Instruction

………..…………………………………………………..

1

………………………………………………………..…………

2

………….……………………………………………………………………

3

………………………………………………………………………………………

4

……………………………………………………………………………………………

7

EC Decl r tion of Conformity

…………………………………………..………………