Maintenance Manual DG-300

Issued: August 2020 TN DG-SS-05 0.6

Copyright DG Flugzeugbau GmbH - any copy or publishing prohibited

Manual valid with the up-to-date cover page only

Section content page

4 Detailed instructions for assembly and servicing work.............................4.1

4.1 Replacement of the water ballast bags...................................................4.1

4.2 Replacement of control circuit cables....................................................4.1

4.3 Adjustment work on the control circuit.................................................4.2

4.4 Removal and installation of the retractable landing gear......................4.2

4.5 Removal and installation of the fix landing gear...................................4.3

4.6 Removal and reinstallation of the ailerons.............................................4.4

4.7 Increasing the aileron massbalancing ....................................................4.7

4.8 Fixing excessive free play of the canopy...............................................4.8

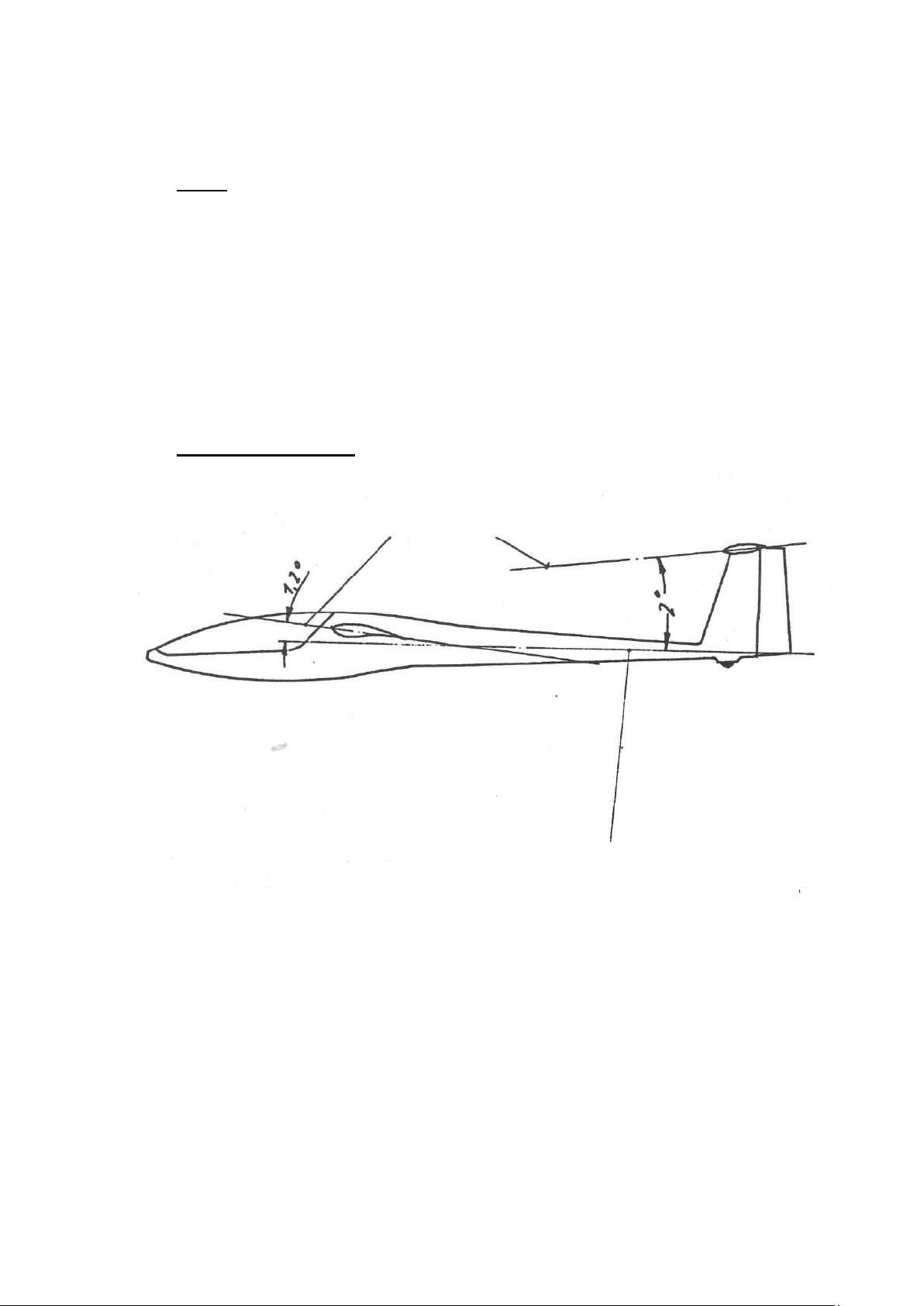

5 Centre of Gravity measurements-weighing ...............................................5.1

6 Instrument- und equipment list ..................................................................6.1

6.1 Air speed indicator (0 - 300 km/h, 165 kts)...........................................6.1

6.2 Altimeter.................................................................................................6.1

6.3 Harness (seat).........................................................................................6.1

6.4 Compass (as min. equipment only necessary for cloud flying).............6.2

6.5 VHF transceiver .....................................................................................6.2

6.6 Variometer (as min. equipment only necessary for cloud flying) .........6.2

6.7 Turn and bank indicator (as min. equipment only necessary for cloud

flying)......................................................................................................6.2

6.8 Outside air temperature gauge ...............................................................6.3

6.9 Beschleunigungsmesser .........................................................................6.3

6.10 Instruments which are not part of the minimum equipment:.................6.3

7 Liste der Spezialwerkzeuge........................................................................7.1

8 Diagrams ....................................................................................................8.1

Diagram 1 Elevator control circuit, adjustment 8.1

Diagram 2 Rudder control circuit, retractable landing gear ..............................8.2

Diagram 3 Fix landing gear................................................................................8.3

Diagram 4 Aileron and spoilers control circuits, wheel brake...........................8.4

Diagram 5 Tow hook, water ballast release systems DG-300, DG-300 ELAN,

DG-300 ELAN ACRO.......................................................................................8.5

Diagram 6 Tow hook, water ballast release systems DG-300 Club ELAN, DG-

300 Club ELAN ACRO.............................................................................8.6

Diagram 7 Empty weight centre of gravity range..............................................8.7

Diagram 8 Placards DG-300 & DG-300 ELAN................................................8.8

Diagram 9 Placards DG-300 ELAN ACRO ......................................................8.9

Diagram 10 Placards DG-300 Club ELAN......................................................8.10

Diagram 11 Placards DG-300 Club ELAN ACRO .........................................8.11

Diagram 12 Placards if TN359/24 instruction A is applicable........................8.11