1. Setting up Machine for Work

Unpack machine from its shipping box, making certain that you remove from box

all component parts and accessories.

A.

Location

(Figs.

1-2)

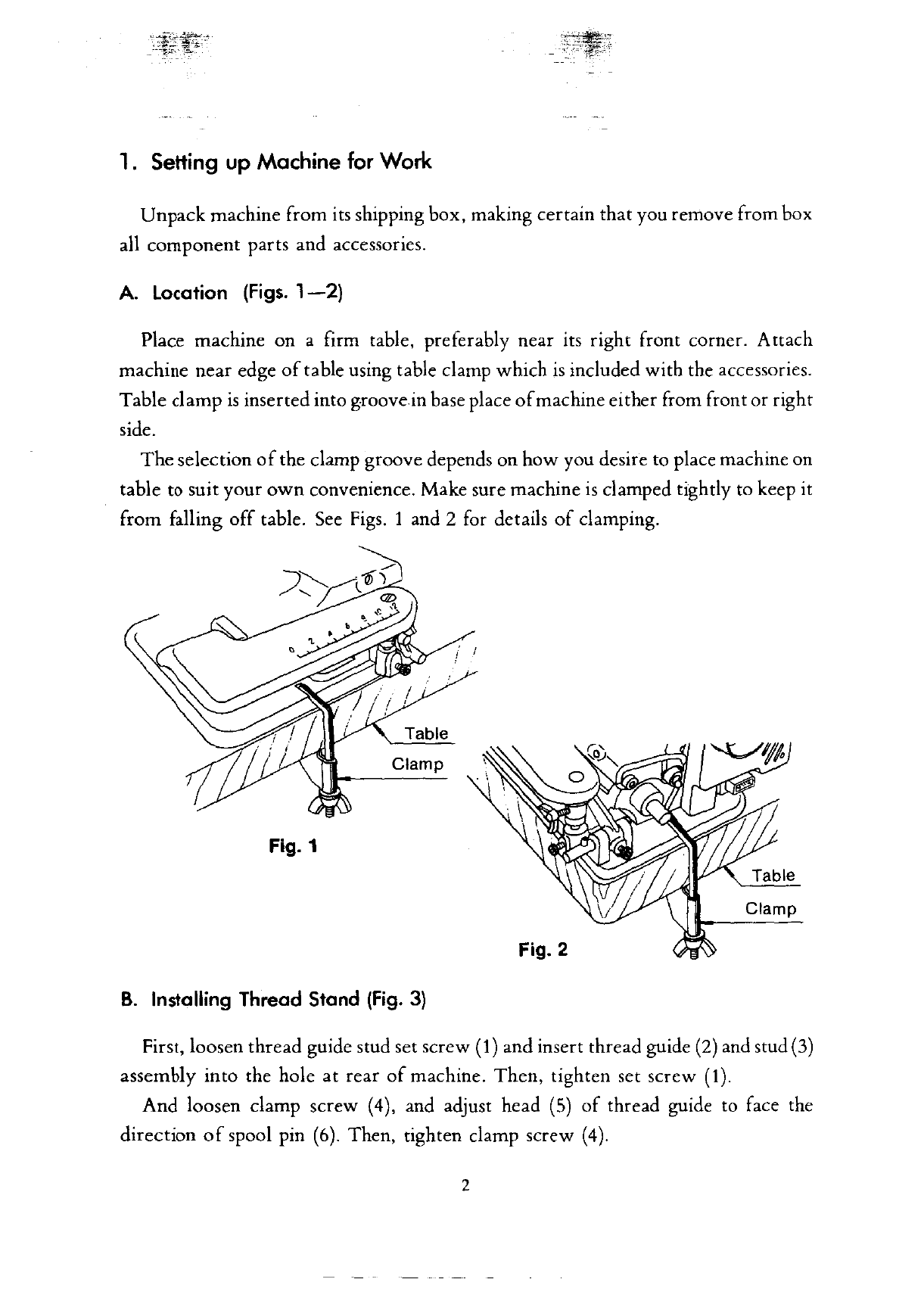

Place machine on a firm table, preferably near its right front corner. Attach

machine near edge

of

table using table clamp which

is

included with the accessories.

Table clamp

is

inserted into groove in base place

of

machine either from front or right

side.

The

selection

of

the clamp groove depends on how you desire to place machine on

table

to

suit your

own

convenience. Make sure machine

is

clamped tightly to keep it

from falling

off

table. See

Figs.

1 and 2 for details

of

clamping.

~

/~l~___.)--...

•

'

•

Fig. 1

'

b

Table

Clamp

Fig. 2

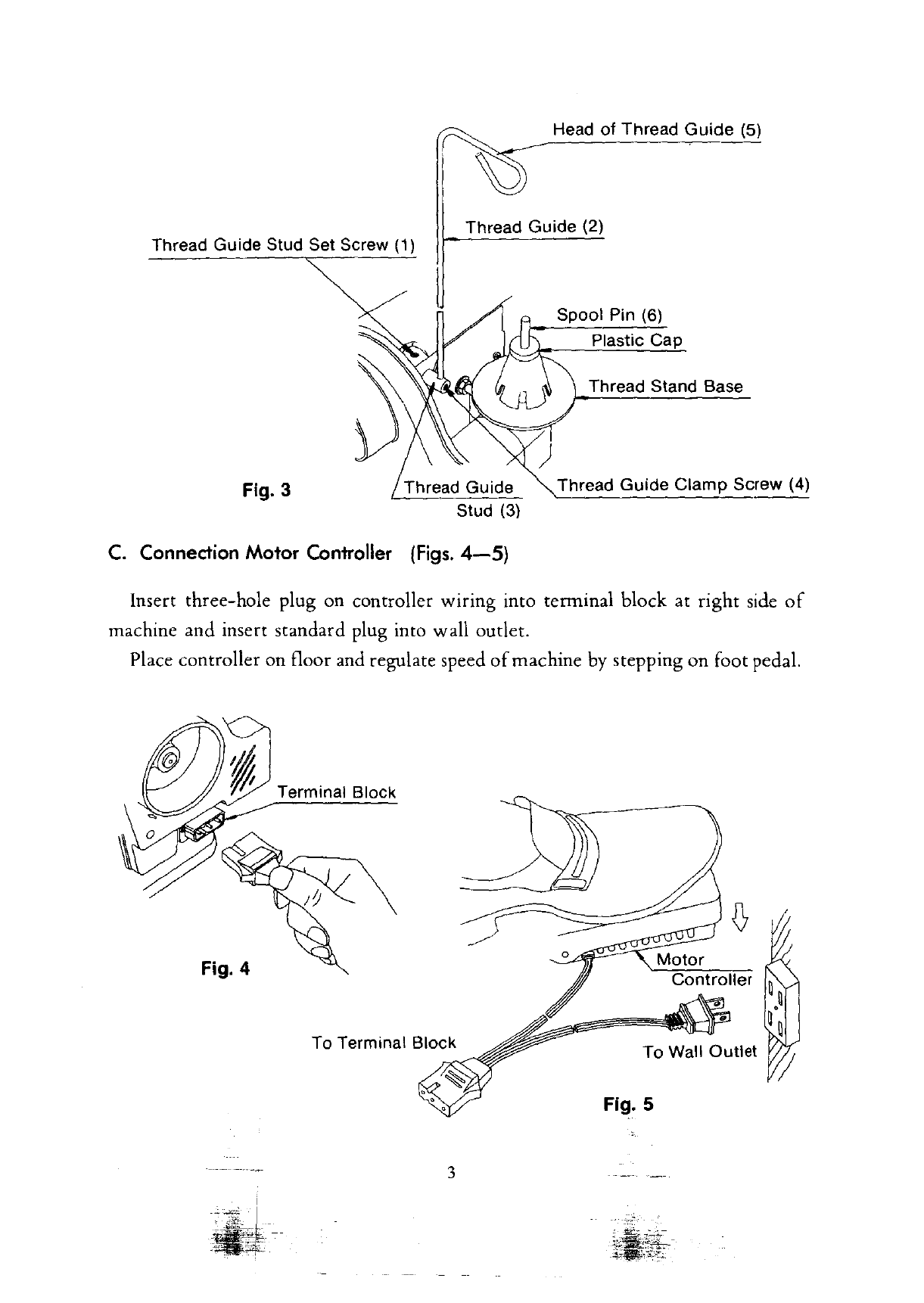

B.

Installing Thread

Stand

(Fig.

3)

Clamp

First, loosen thread guide stud set screw (1) and insert thread guide

(2)

and stud

(3)

assembly into the hole at rear

of

machine. Then, tighten set screw

(1).

And loosen clamp screw (4), and adjust head

(5)

of

thread guide to face the

direction

of

spool pin

(6).

Then, tighten clamp screw

(4).

2

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com