4.1

Preliminary

Checks

Remove

front

case

and

conuols

uay. Turn the

gas

"Ofl', turnwateron and

checkfor watcrleakage

around

thcheater.

Relit thcoutcr

cascand

sccurc.

Turnthcgas

servicc

cock

"On". It is on when

the

screw

driverslot is in linc with thecock. It is otf

whenthescrewdriver

slotis acrosstheaxis

of thc

cock,

secdiagram8.

Turn

thc

watcr

supply

on in a similar

manncr

the

gas

supply,sccdiagram

7 andchcck

that

waterthrottlc

is not fully closcd,

sec

diagram

Opcn

all hotwatcrdrawoff taps

individually

wait until thc waterflorvsfrccly. Closc

each

off taoin turn.

lrl

the

10.

and

draw

4.2

To Lightthe Pilot

Turnthc

gas

supply

on. Fully

depress

the

"grs on"

button

I andoperate

thespark

ignitionbutton,Arz

untilthc

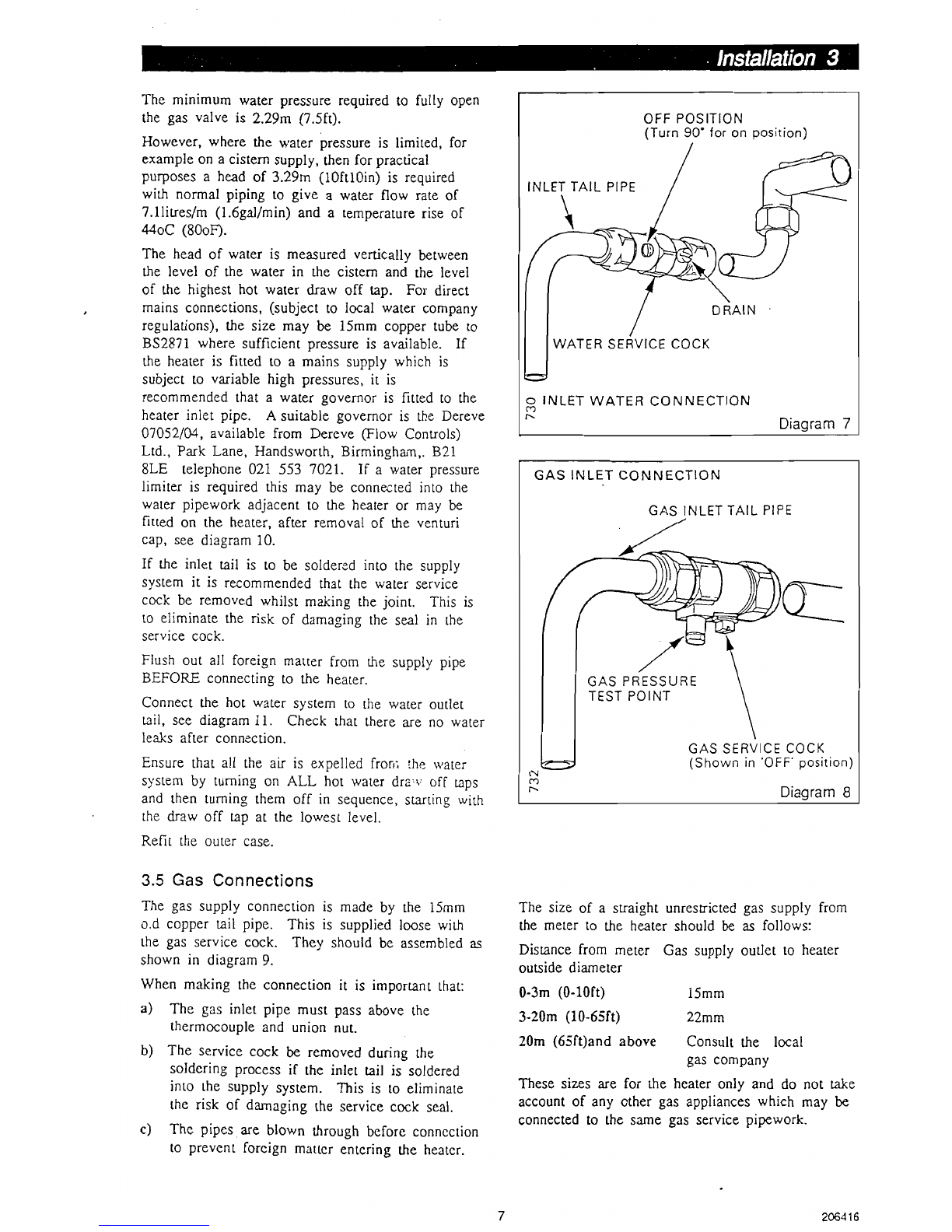

pilotis lit, seediagram9.

Thc

pilot,

which

is situatcd

to thclcft hand

sidc

oi

thc

hcater

may

bc sccn

throughthe

pilot

vicrving

window,

sec

diagram

9.

Kccpthc "gas

on" buLton

I pressedin for l0

scconds

thcn

rcleasc.If thcpilot gocs

out purgc

thcsystcmand

rcpcatthc

opcration.

4.3Adjustmentof Water

Temperature

Opcn thc HOT water draw-off up furrhcst

from thc

hcatcr. Ensurc

thatthe "SummerAVinter"

control

is

in thc "Wintcr" position,

sccdiagram

9. Adjustthc

watcr

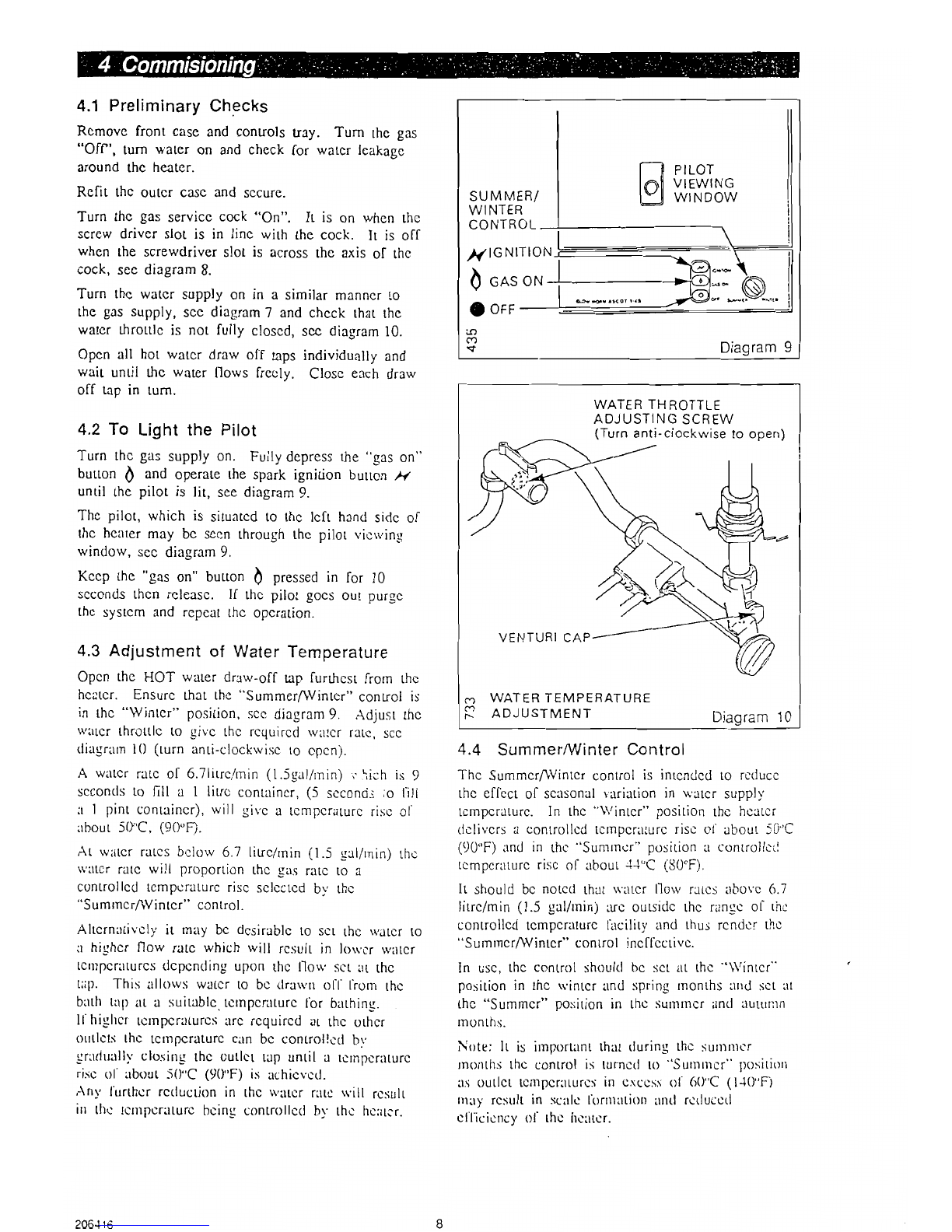

[hrottlcto givc thc rcquircd

\viltcr

ratc,

scc

tliagrarn

i0 (turn anti-clockrviscto opcn).

A watcrratc ol 6.7litrc/rnin

(i.5gal/rnin)r \ii:h is 9

scconds

to fill a I litrc contirincr,

(5 scconcjs

;o t'ill

a I pint

contlincr),

will givc a [cmpcraturcriscol.

rbout 50"C,

(90"R.

Ar watcrratcs

bclorv

6.7 litrc/rnin

(1.5 g:rl/rnin)

thc

\\':.ltcrratc will proportion thc sas ratc to a

controllcd

lcmpcralurc

riscsclcctcd

by'thc

"SumrncrAVintcr"

control.

Ahcrnutivcly

it may bc dcsirablc

to sct thc \\,atcr

to

lu

highcrflow ratc which rvill rc.sulIin lorvcr

rvirtcr

tcn)pcrilturc.,i

dcpcndingupon thc llo\\' sr'tilt thc

tilp. This allorvs watcr to bc tlrarvrtot't'

l'rom thc

butlr

t:.rp

at a suiublc.

[ctnpcri.lLurc

lbr bitthins.

ll'highcr tcrnpcrilturcs

rrc rcquircd

at thc othcr

orrtlcts

thc tcrllpcraturc

ciln bc controll'--d

bv

grlrlualll'

closirt{ thc out['t tap until a tcrl]pcri.lturc

risc ol' about -iO"C

(90"F) i.sachicvcd.

'\n1' lirrthcrrctluction

in Ihc rr'utcr

rat.c

*'ill rcsult

irrtlrc tr'rnpcrlturcbcingcontrollctl

b1'thc hcutcr.

4.4 SummerMinter

Control

Thc SummcrAVintcr

control

is intcndcd

to rcducc

the eflcct

of scasonal

variationin u'atcr

supply'

tcmpcrilturc.

In thc "\\'intcr" position

thc hcltcr

clclivcrs

a controllcti

tctnpcraturc

riscol abouL

50''C

(90"F)

and in thc "Sumrncr"

pt-rsition

a controllc'il

tcmpcri.rturc

ri.scof about

-l-l"C (80'F).

It shoulri

bc notctl lhat *ittcr llorv ratcsitbovc 6.7

litrc/min

(1.5gal/rnin):rc outsiclc

thc ranScof thc

controllcd

tcmpcritturc

tacilit,vand thusrcndcr

thc

"surnrncrAVintcr"

control

incfl'cctivc.

In usc,

thc controlshould

bc sct at thc "\\'intcr"

positionin thc s'intcr

and spring

rnonthsttrtd

sctItt

thc "Summcr"position

in thc sunrlncr

antlauttlllln

rnonths.

Note: lt is importltnt

thrt tluring

lhc sutl]ttlt-r

rnonth.Jthc control

is turnctl

ttl "Surnrncr"

llosititlrr

i,l:ioutlct tctltpcrilturcs

in crccss tll' (10''C

(lJ(I'F)

rnuy

rcsult

in scllc lbrrttation

lttltl

rctlucctl

cll'icicncy

ol' thc he-iltcr.

P

ILOT

VIEWING

WINDOW

SU

MMER/

WINTER

CONTROL

//rGNlTlON

I cot

ot

O

orr

T Diagram

9

WATERTHROTTLE

ADJUSTING

SCREW

(Turn

anti-clockwise

toopen)

N

VENTURI

WATER

TEMPERATURE

ADJUSTMENT I-\i^^zrm 1A

ulo9rqrrl lv

zuo{ |o