4.1 Siting

IMPORTANT. With regards to the Manual Handling

Operations, 1992 Regulations, the following lift operation

exceeds the recommended weight for a one man lift.

Locate the Glow-worm cylinder in the building in the most

convenient position ensuring that:

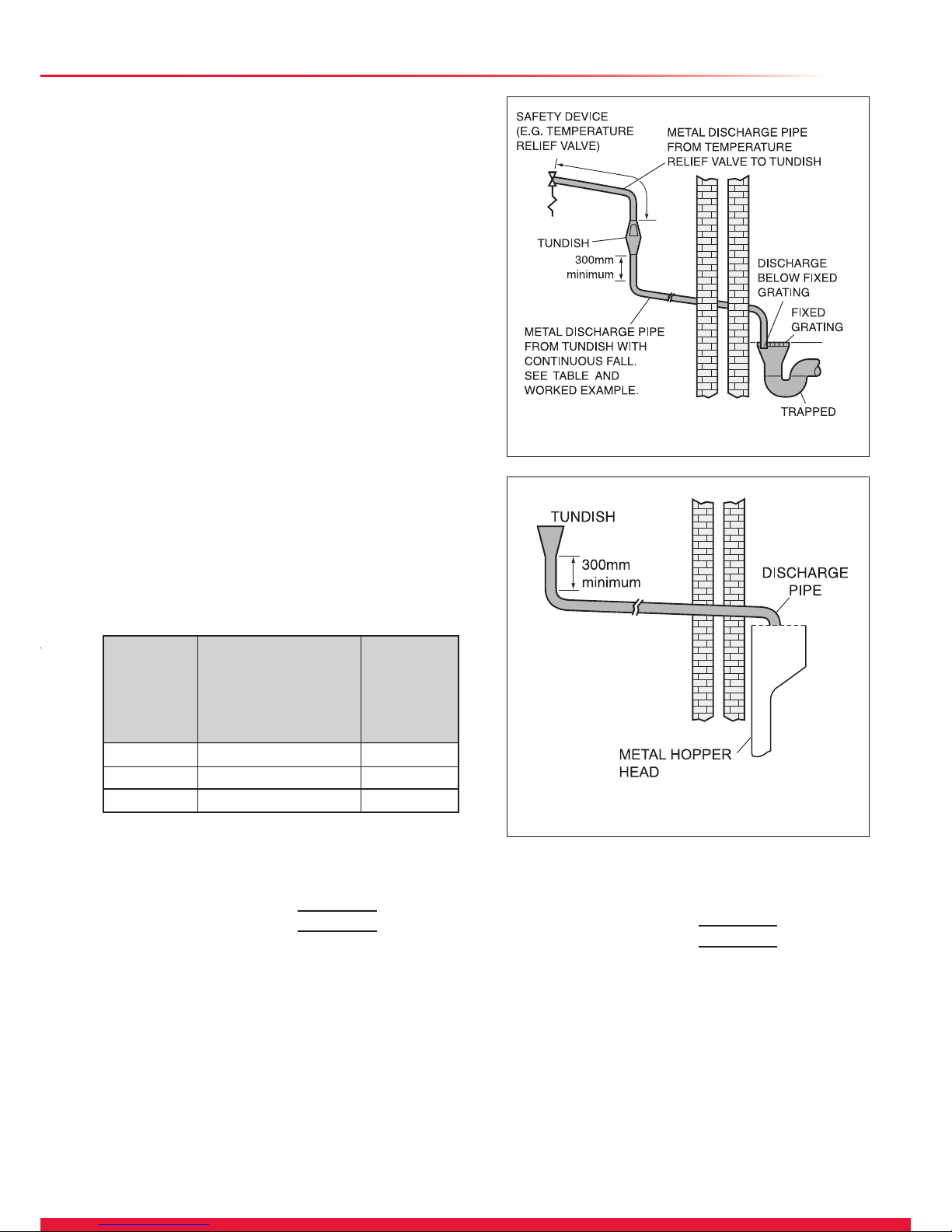

1. The discharge pipe from the tundish can be installed with a

minimum fall of 1:200 and must be terminated in a safe and

visible position (see section 4.4 Discharge pipework).

2. The base chosen for the unit is level and capable of

supporting the weight of the cylinder when full (see section 1

Technical Data).

3. The installation site is frost-free. If necessary provide a frost

protection thermostat.

4. Access is available for user operation of the DHW

temperature control under the front panel.

5. Suitable clearances exist to allow installation, checking and

repressurising of the expansion vessel.

6. The installation site chosen does not result in excessive

”dead leg” distances, particularly to the point of most frequent

use.

7. A suitable cold mains water supply pipe can be provided to

the Glow-worm cylinder direct from the main water stop valve

of the building.

8. The cylinder is factory equipped with adjustable feet to

allow for uneven oor surface.

This product has been assessed and found to comply with

the requirements of the Building Regulations for unvented hot

water storage systems and must not be altered or modied in

any way.

The installation must be carried out by a competent person

approved at the time by the Health and Safety Executive

and be in accordance with the relevant requirements of the

Local Authority, Building Regulations, Building Regulations

(Scotland), Building Regulations (Northern Ireland), and the

bye-laws of the local Water Undertaking. The installation

is subject to Building Regulation approval, notify the

Local Authority of intention to install. In the event of parts

replacement, use only genuine spare parts supplied by Glow-

worm.

3.1 DHW System

The Glow-worm cylinder is provided with all necessary safety

and control devices for unvented DHW operation.

These are as follows:

A Temperature (95°C) and pressure relief valve (7 bar) factory

tted.

B A Thermal cut set at 90°C which when wired to the 2 port

valve will isolate the heat source in the event of failure of

the cylinder thermostat.

C A cylinder thermostat (20°C - 65°C)

D Expansion relief valve (6.0 bar) incorporating a non return

valve.

E Pressure limiting valve (3.5 bar) incorporating a line strainer.

3 Note to Installer

4 Installation

4.2 Mains Water Pressure

The DHW performance of an Glow-worm unvented cylinder

installation will depend on to the available mains water supply

pressure and ow rate. To achieve optimum performance

from the Glow-worm cylinder a suitable cold mains water

supply must be available, i. e. the measured static pressure

from the incoming mains water supply should be at least 2.0

bar. A corresponding ow rate at least 20-25 l/min should be

available.

NOTE: Mains water pressure will be reduce during periods of

peak demand. Ensure that measurements are taken during

these periods.

Example: If the measured cold mains supply pressure is 2

bar static and the cold mains ow rate available is 30 l/min,

the available ow rate of mixed water at 40°C will be 25 l/min

(from 15 l/min hot water from the Glow-worm cylinder @ 60 °C

together with 10 l/min cold water @ 10°C).

The Glow-worm cylinder will operate satisfactorily with water

supply pressures below 2 bar although ow rates will be

reduced. If the supply pressure is below 1 bar the Glow-worm

cylinder should not be installed. Contact Glow-worm for details

on alternative hot water supply systems.

In order to minimise frictional losses minimum 22 mm bore is

recommended for new cold mains supply pipework into the

dwelling although satisfactory performance can be achieved

with 15 mm bore pipework.

Check that the cylinder has been supplied with the following:

Packed inside cylinder carton

• Water control pack (pressure reducing valve, expansion

relief valve; connections for: balanced cold water, secondary

return, expansion vessel)

• Motorised 2 port valve

• Tundish

• Instructions for Use, Installation and Servicing.

Expansion vessel:

• 12 litre for Glow-worm cylinder SS 115/SS 150

• 18 litre for Glow-worm cylinder SS 175/SS 200

• 25 litre for Glow-worm cylinder SS 250/SS 300

• Four compression ttings

Accessory: Mounting bracket No. 0020000000

Prior to installation, ensure that the Glow-worm cylinder is

stored upright in dry conditions.

Please also refer to “General Requirements“ in the installation

instructions supplied with the boiler.

3.2 DHW Secondary Return

A secondary return connection is provided in the water control

pack.

Remove the 3/4 BSP blanking plug from the water control

group using an appropriate tting. Using a WRAS approved

circulation pump which incorporates a check valve to prevent

backow (see g. 6). The secondary connection can be made.

8