Table of Contents

Preface .............................................................3

„

Safety precautions................................................4

Chapter 1 BEFORE USING THE INVERTER....1-1

1.1 Acceptance Inspection .............................. 1-1

1.2 External Views........................................... 1-2

Chapter 2 MOUNTING AND WIRING OF THE

INVERTER........................................2-1

2.1 Operating Environment ............................. 2-1

2.2 Installing the Inverter................................. 2-1

2.3 Wiring........................................................ 2-2

2.3.1 Removing and mounting the terminal

block covers...................................... 2-2

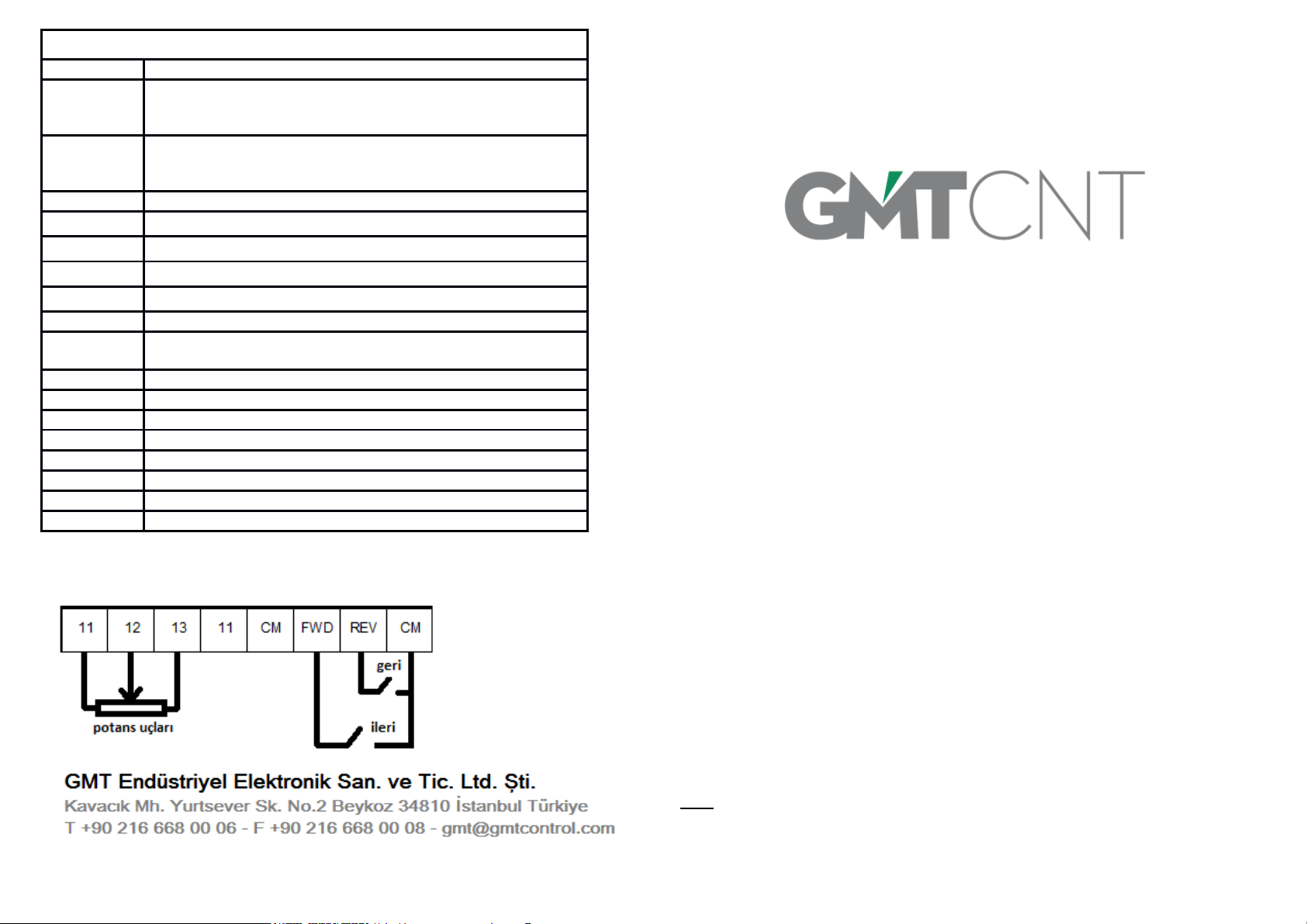

2.3.2 Terminal arrangement and screw

specifications .................................... 2-3

2.3.3 Recommended wire sizes................. 2-5

2.3.4 Wiring precautions............................2-7

2.3.5 Wiring for main circuit terminals and

grounding terminals ..........................2-8

2.3.6 Wiring for control circuit terminals... 2-11

2.3.7 Setting up the jumper switches.......2-18

Chapter 3 OPERATION USING THE KEYPAD . 3-1

3.1 Names and Functions of Keypad

Components.............................................. 3-1

3.2 Overview of Operation Modes...................3-2

Chapter 4 RUNNING THE MOTOR ...................4-1

4.1 Test Run.....................................................4-1

4.1.1 Checking prior to powering on...........4-1

4.1.2 Powering ON and checking...............4-1

4.1.3 Preparation before a test run

--Configuring function code data........4-2

4.1.4 Test run..............................................4-3

4.2 Operation...................................................4-3

Chapter 5 FUNCTION CODES............................5-1

5.1 Function Code Tables ................................5-1

Chapter 6 TROUBLESHOOTING ......................6-1

6.1If an Alarm Code Appears on the LED

Monitor......................................................6-1

6.2If anAbnormal Pattern Appears on the LED

Monitor while No Alarm Code is Displayed

....................................................6-3

Chapter 7 MAINTENANCE AND INSPECTION .7-1

7.1 Daily Inspection..........................................7-1

7.2 Periodic Inspection.....................................7-1

7.3 List of Periodical Replacement Parts.........7-3

7.4Inquiries about Product and Guarantee.....7-4

7.4.1 When making an inquiry....................7-4

7.4.2 Product warranty ...............................7-4

Chapter 8 SPECIFICATIONS.............................8-1

8.1 Standard Models........................................8-1

8.1.1 Three-phase 200 V class series........8-1

8.1.2 Three-phase 400 V class series........8-2

8.1.3 Single-phase 200 V class series .......8-3

8.2Terminal Specifications ..............................8-7

8.2.1 Terminal functions..............................8-7

8.2.2 Connection diagram in operation

by external signal inputs....................8-7

8.3Protective Functions ................................8-11