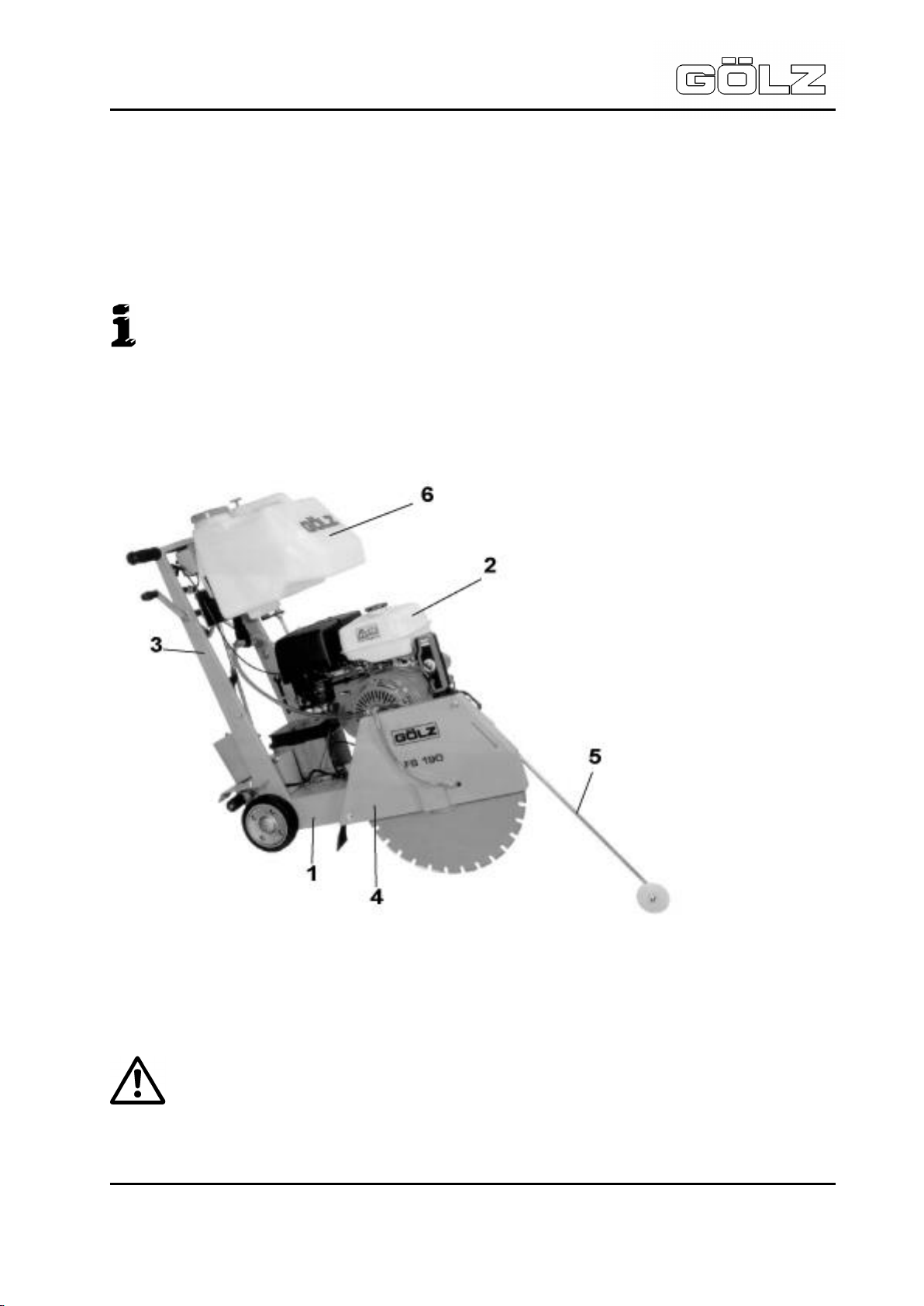

FS 190

Operating instructions

- 7- 02821900988

5005967-04

2.5 Special work related to the maintenance and repair of the machine

Observe the adjustment, maintenance and inspection activities and intervals set out in the operating

manual, including information on the replacement of parts or assemblies! These activities may be

performed by skilled personnel only.

Brief the operating personnel before initiating special repair or maintenance activities. Appoint a

person to supervise such activities. In any work concerning the operation, adaptation to production

requirements, conversion or adjustment of the machine and it’s safety-oriented devices or any work

related to inspection, maintenance and repair, always observe the start-up and shut-down procedures

described in the operating manual as well as the instructions on maintenance activities!

If necessary, secure a large area around the location where maintenance of the machine is to be

performed. Maintenance and repair work may be carried out only if the machine is placed on level and

solid ground and secured against inadvertent movement. If the machine is completely shut down for

maintenance or repair work, it must be secured against inadvertent restarting.

When using a lifting gear for replacing individual parts or large assemblies make sure that the parts/

assemblies are carefully attached to the lifting gear and secured in place to avoid hazardous

conditions. Use only suitable and technically perfect lifting gear and suspension systems with

adequate lifting capacity! Never work or stand under suspended loads! The fastening of loads and the

instructing of crane/industrial truck operators should be entrusted to experienced persons only!

The instructor must be within sight or sound of the operator. Use an intercom system if necessary.

When carrying out overhead work always use specially designed or other safety-oriented ladders and

working platforms. Never use machine parts as a climbing aid! Wear a safety harness when performing

maintenance work at greater heights! Keep all handles, steps, handrails, platforms, landings and

ladders in a clean condition!

Before performing any maintenance/ repair activities clean the machine, especially the connectors and

screwed joints, and remove any oil, dirt and preservative agents. Never use aggressive detergents!

Use lint-free cleaning rags!

Before cleaning the machine with water or other cleaning agents cover or tape up all openings which -

for safety and functional reasons- must be protected against the ingress of water/ steam/ cleaning

agents. Special care must be taken with bearings, electric motors and electronic systems. After

cleaning, make sure to remove all covers/ tapes from the openings. After cleaning, check all cables

and hydraulic fluid lines for leaks, loose connections, chafe marks and damage! Have any defects

found rectified immediately!

Always retighten any screwed connections that have been loosened during maintenance/repair activi-

ties!

Any safety devices removed for set-up, maintenance or repair purposes must be refitted and checked

immediately upon completion of the set-up, maintenance or repair work.

Avoid any operation that might affect the stability of the machine. Always keep a sufficient distance

from the edges of excavations, ditches and slopes!

Before leaving the machine always secure it against inadvertent movement and unauthorized use!

Ensure that all process materials and replaced parts are disposed of safely and with minimum environ-

mental impact!

2.6 Information about special risks electrical energy

Observe the relevant national regulations or standards. Electrical connections must always be kept

free from dirt and moisture. Use only original fuses with the specified rating! Switch off the machine

immediately, if trouble occurs in the electric power supply!

When working with the machine, maintain a safe distance from overhead electric lines. If work is to be

carried out close to overhead lines, the working equipment must be kept well away from them.

Caution, danger! Check out the prescribed safety distances.

If your machine comes into contact with a live wire:

warn others against approaching and touching the machine

have the live wire de-energized