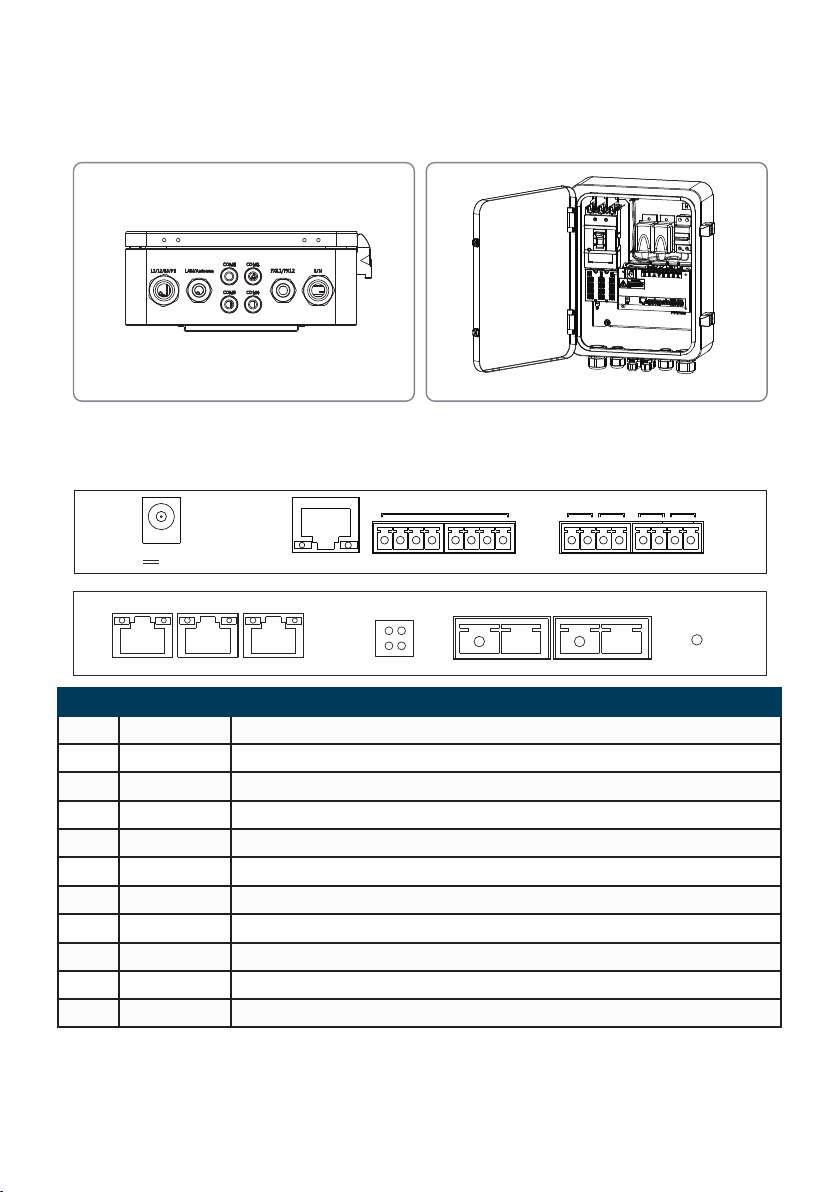

4.5.2 PLC Wiring Instructions

(a) Protective Earth Wiring:

The protective ground wire is connected to the PE of the base plate of inside the SCB3000 enclosure.

(b) Remove the three-phase AC power line cover panel.

(c) Connect the three-phase AC power line.

Notice: Before connecting the AC power line, make sure that the switch upstream of SCB3000 is open.

Three-phase input line voltage range: AC342V~AC800V; AC frequency: 50Hz/60Hz.

The three-phase AC power line is connected to the transformer bus, and then to the circuit breakers L1, L2 and L3 in

the SCB3000 via port (1).

(d) Install the three-phase AC power line cover panel.

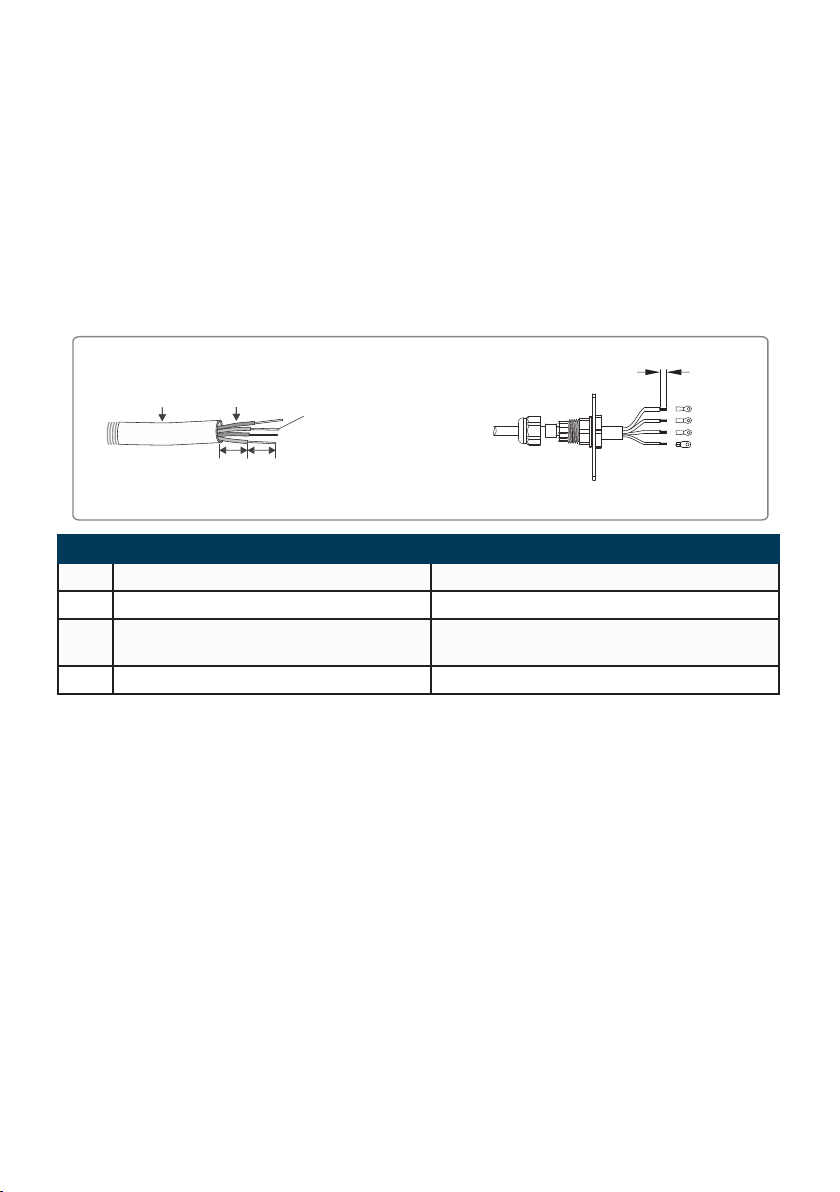

AC Input wire specications and crimping:

Plier Crimping

6~8mm

L1

L2

L3

PE

Flexible stranded copper wire

AB

C D

Code Description Value

A Wire outer diameter No greater than 25mm

B Cross-sectional area of copper conductors Recommend for use: 2.5~4mm²

C Wire length Approximately 130mm (approximately 50mm

for PE wire)

D Copper bare wire length 6~8Mm (5~6mm for PE wire)

4.5.3 Description of RS485 communication wiring

COM1, COM2 and COM3 are RS485 ports for communications with the inverter that can be left

unused if communications with inverter PLC can meet the requirements, users can choose to connect

COM1, COM2 or COM3 for communications with the inverter as needed.

If using the SCB3000 to connect with a environment monitor, the connection can be made to the

COM4 port via the RS485 cable.

Notice: 1. COM1, COM2 and COM3 are used only for communications with the inverter, while COM4 is only

connected to third-party equipment such as environment monitors, and must not be connected incorrectly.

2. For RS485 communication wiring, please use standard RS485 communication twisted pair.

3. The maximum number of inverters connected to each of COM1, COM2 and COM3 is 20 units, with the total of 60

units allowed for the 3 ports.

4. In the ports COM1, COM2, COM3 and COM4, A corresponds to the differential signal +, and B corresponds to the

differential signal.

Wire specications and installation: for RS485 communication cables, shielded twisted pair cables with

a conductor cross-sectional area of 1mm² are recommended for use.

08