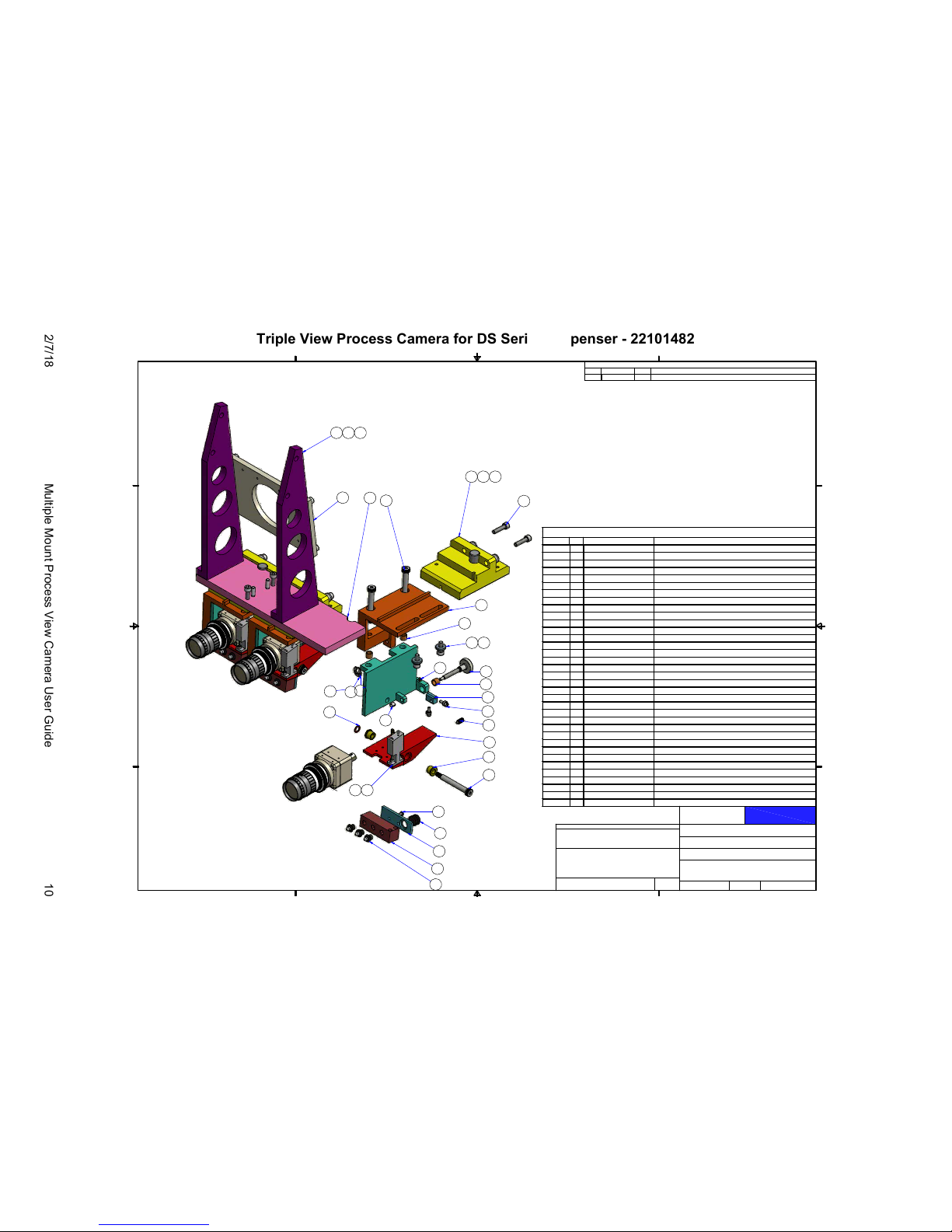

Parts List

DESCRIPTION

PART NUMBER

QTY

ITEM

BEARING,FLANGE,BRZ_1/4ID X 3/8OD X 1/4L

00_003661

WASHER,SPHERICAL #10SCREW10/4146

62

SCREW_SET_10-32X3/8_BRASS TIPPED10_374363

PROCESS VIEW_TRIPLE_CAM SWIVEL221014943

4

PROCESS VIEW_TRIPLE_SPINDLE BASE221014953

5

PROCESS VIEW_TRIPLE_CAMERA INTRFC2210149636

PROCESS VIEW_TRIPLE_LIGHT RISER221014993

7

PROCESS VIEW_TRIPLE_MOUNT MODS2210150038

BOLT_SHOULDER_1/4"_1 1/2_10-242525-004469

BOLT_SHOULDER_1/4_1 3/4_ 10-242525-0045310

DOWEL PIN 1/2 X 1 LONGDA50100311

SHIM_SS_WASHER_1/4ID_3/8ODG6504312

BUSHING, DU - 1/4 ID X 1/4 LGL0301613

GROMMET_1/8"THRU_1/2" OVERALL10_4892314

HOUSING_LIGHT BAR_PROCESS VIEW22101487315

COVER_LIGHT BAR_PROCESS VIEW22101488316

LED ASSY917

SCREW,BUTTON HEAD,4-40 X 1/4 SSTSABSN0440025618

SPRING ANCHOR - 6-32PBT-0119619

10-32 X 1/2LG SHCSSACAN1032050620

CAP SCREW 4-40 X 1/4LG SSTSACSN0440025621

#10 HARD WASHERWFRBH010622

CAM FOLLOWER .250 X .109W10_4326_NO NUT623

PROCESS VIEW_TRIPLE_DRIFT SCREW22101497324

PROCESS VIEW_TRIPLE_CAM BLOCK22101498325

RING,RETAINING,E-STYLE_.250SHAFT,.025THKG1596326

BEARING,SLEEVE,DU_1/8IDX3/16ODX3/16LL0001327

BUSHING, DU - 1/4 ID X 1/4 LGL0301328

WASHER_WAVE_.269ID_.423OD_.07HGTS7012329

BASE PLATE_PROCESS VIEW_3 CAM OPTION22101493130

BRACE_PROCESS VIEW_3 CAM OPTION22101489231

STIFFNER_PROCESS VIEW_3 CAM OPTION22101490132

DOWEL PIN 3/16 X 1/2LGDA18050433

CAP SCREW 10-32 X 1/2LG SSTSACSN1032050834

CAP SCREW 10-32 X 3/4LG SSTSACSN1032075635

1

1

2

2

3

3

4

4

A A

B B

C C

D D

DWG SIZE

DWG NO

SHEET OF

DRAWN BY

DESCRIPTION

ASSEMBLY

FINISH MATERIAL

TOLERANCES UNLESS OTHERWISE SPECIFIED

FRACTIONS B1/32

HEAT TREATMENT

X.XX B0.015

X.XXX B0.005

ANGULAR B0.5`

RUNOUT B0.003 T.I.R.

METRIC

0.0 MM B0.4 MM

0.00 MM B0.1 MM

GPD Global

PROCESS VIEW_3 STATION_3 CAMERAS

22101482

1 1

CBM 10/26/2016

DS SERIES PROCESS VIEW

AS NOTED

NA

0 MM B1.0 MM

REVISION HISTORY

REV DATE BY DESCRIPTION

-- - ORIGINAL ISSUE

AS NOTED

LAST REVISED 11/08/2016

31 34 33

32 35

8 2 11

13

22 20

24

28

23

27

12

3

4

1

10

14

16

15

17

18

19

7

21

5

6

25

30 9

26 29