Table of Contents

23A7633A

NOTE: Photographs may include optional equipment.

Table of Contents

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . 3

Recommended Tools and Supplies . . . . . . . . . . . . . . 4

Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . 4

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . 6

Zerk Fittings ...................................................6

Grease Point Fitting Locations . . . . . . . . . . . . . . 7

Grease Point Fitting Table . . . . . . . . . . . . . . . . . 7

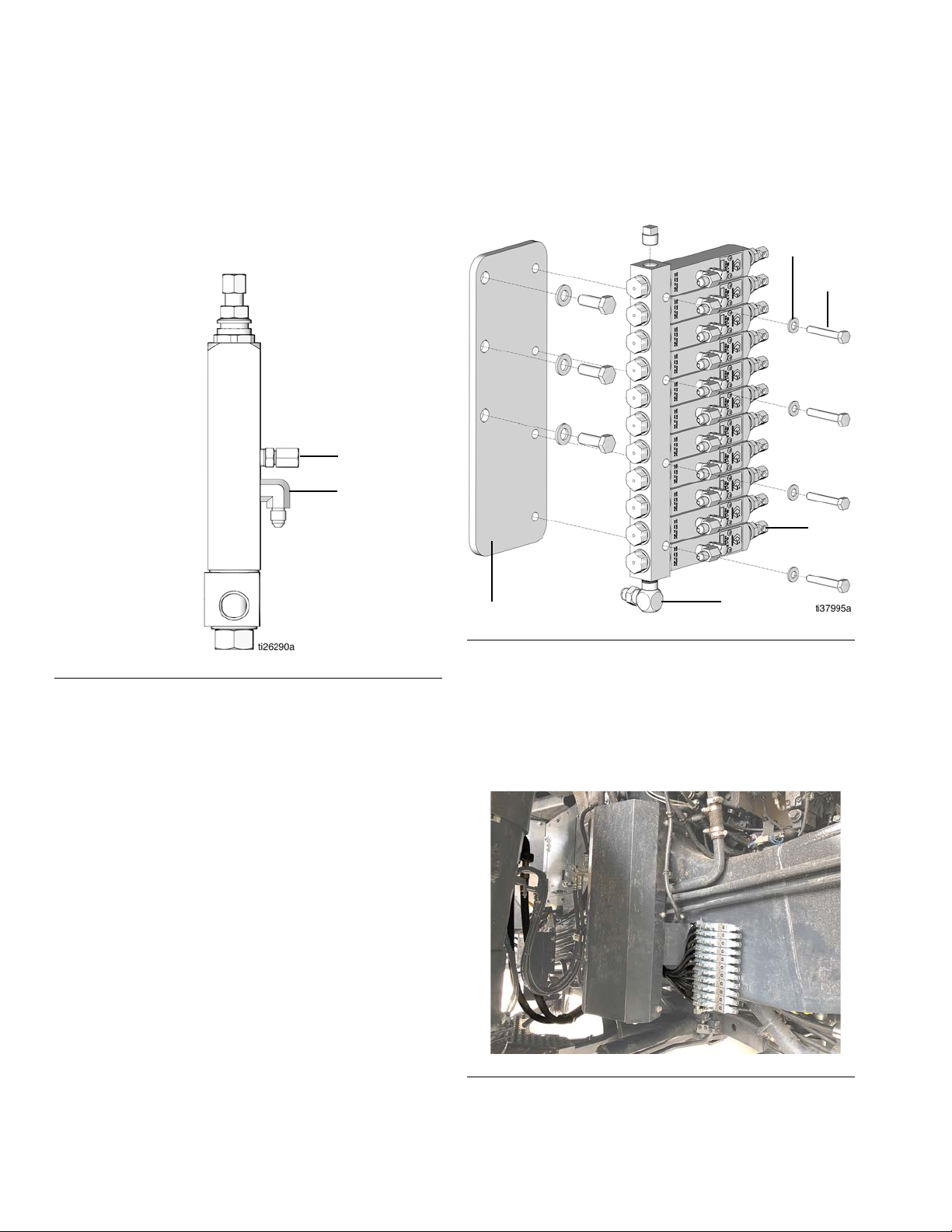

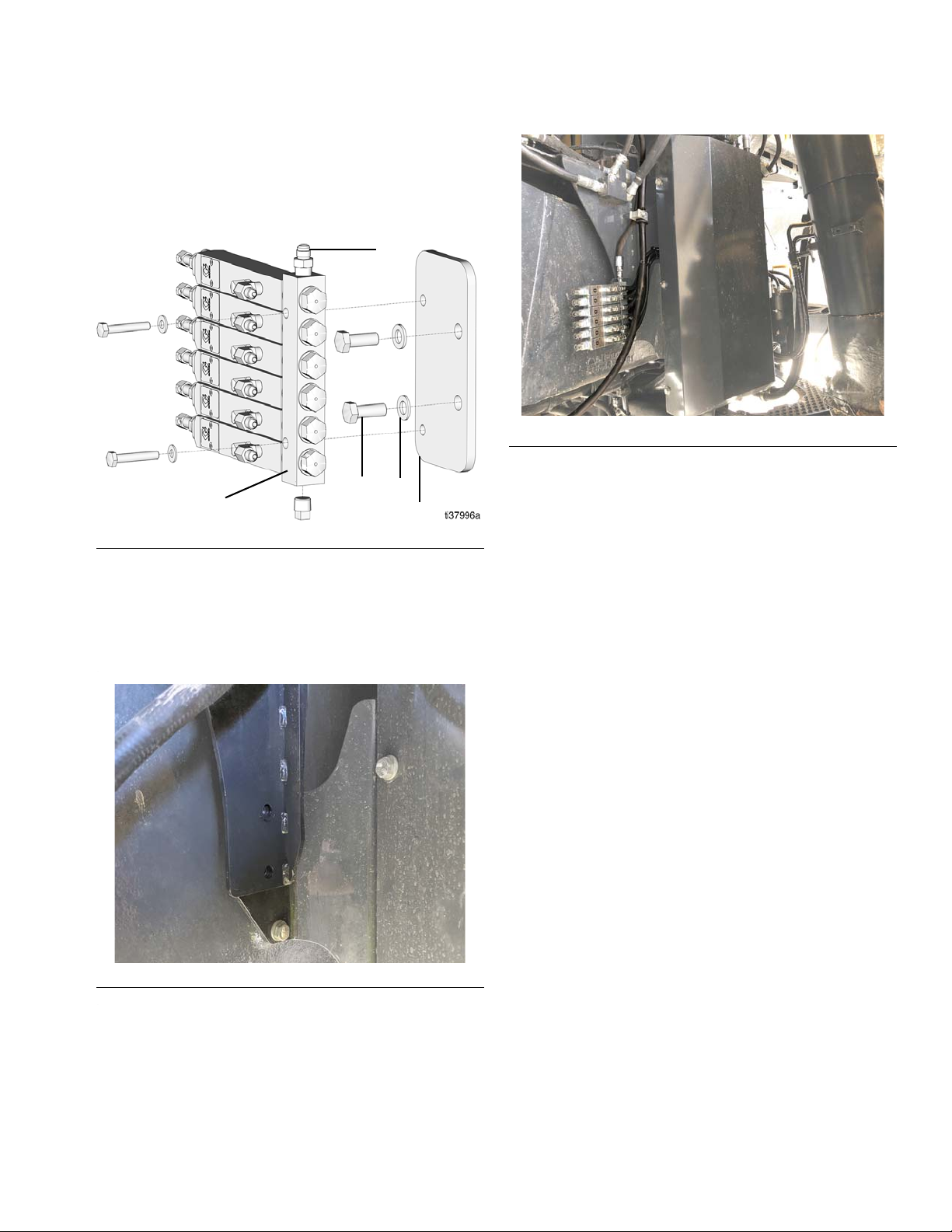

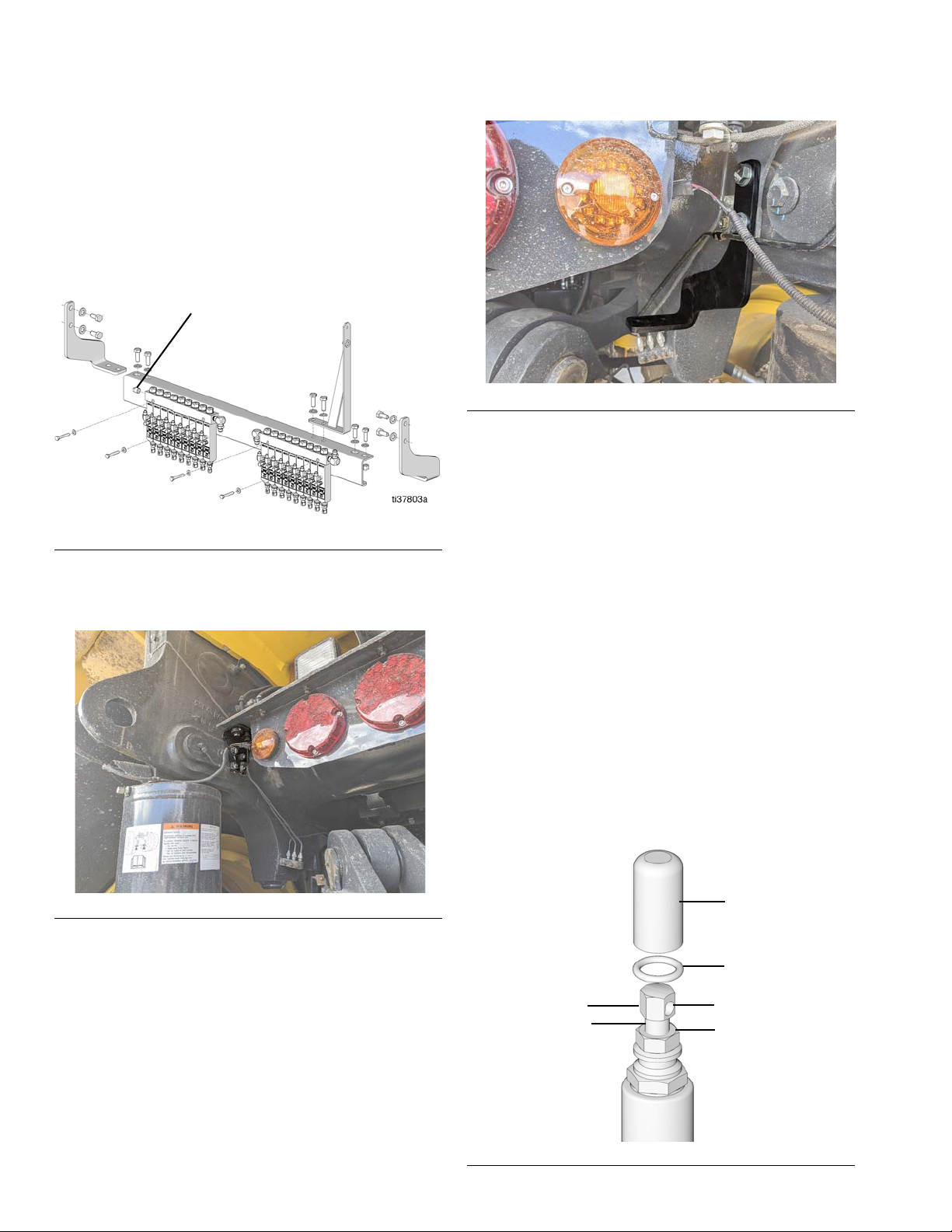

Injector Assembly and Installation . . . . . . . . . . . 8

Left Side Injectors ..........................................8

Right Side Injectors .......................................9

Rear Injectors .............................................. 10

Set the Injector Output ................................. 10

Injector Volume Output Adjustment Table ... 11

P-Clamp Weld Studs . . . . . . . . . . . . . . . . . . . . . 12

Lower A-Arms .............................................. 12

Dump Body Cylinder Pins ............................ 13

Remote Fill Manifold . . . . . . . . . . . . . . . . . . . . . 14

Assembling the Manifold ............................. 14

Remote Fill Manifold Installation .................. 14

Compact Dyna-Star (CDS) Pump Assembly . . . 15

Fitting Table ................................................. 15

Pump Installation . . . . . . . . . . . . . . . . . . . . . . . 15

Pump Harness Extension ............................ 18

GLC X Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Bracket Assembly . . . . . . . . . . . . . . . . . . . . . . . 20

GLC X Cable Routing . . . . . . . . . . . . . . . . . . . . 23

GLC X Power Cable Connection . . . . . . . . . . . 26

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 27

GLC X Controller Component Identification 28

(A) System LED ........................................... 28

(B) Low Level Status LED ........................... 28

(D and E) UP and DOWN Direction Arrows 28

(F) RIGHT Direction Arrow / MANUAL

RUN / ENTER ....................................... 28

(G) LEFT Direction Arrow / Reset ................ 28

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Navigating Setup and Data Entry . . . . . . . . . . . 29

Change Settings . . . . . . . . . . . . . . . . . . . . . . . . 29

Mode ........................................................... 29

End On ........................................................ 29

Low Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Sensor ......................................................... 30

Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Enable a Lock out PIN ................................ 30

Entering a PIN ............................................. 30

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Output 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Date and Time ............................................ 30

Additional Advanced Features . . . . . . . . . . . . . . 30

Hose Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installing the Main Feed Line Junction . . . . . . . 31

Hose Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 31

Hose Assembly Instructions . . . . . . . . . . . . . . . 31

Hose Length Table . . . . . . . . . . . . . . . . . . . . . . 33

Main Fill Line and Remote Fill Lines ........... 34

Right Side Injector Manifold and Main

Feed Line .............................................. 37

Left Side Injector Manifold .......................... 38

Rear Injector Manifold ................................. 38

Secondary Feed Lines . . . . . . . . . . . . . . . . . . . . 39

Left Side Injector Assembly ........................ 39

Right Side Injector Assembly ....................... 41

Rear Injector Assembly. .............................. 42

P-Clamp Installation . . . . . . . . . . . . . . . . . . . . . 44

Fill the Injector Secondary Feed Hoses . . . . . . . 45

Fill Main Lines and CDS . . . . . . . . . . . . . . . . . . 45

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . 52