OPERATION

STARTUPSHUTDOWNANDCARE

OF

UNIT

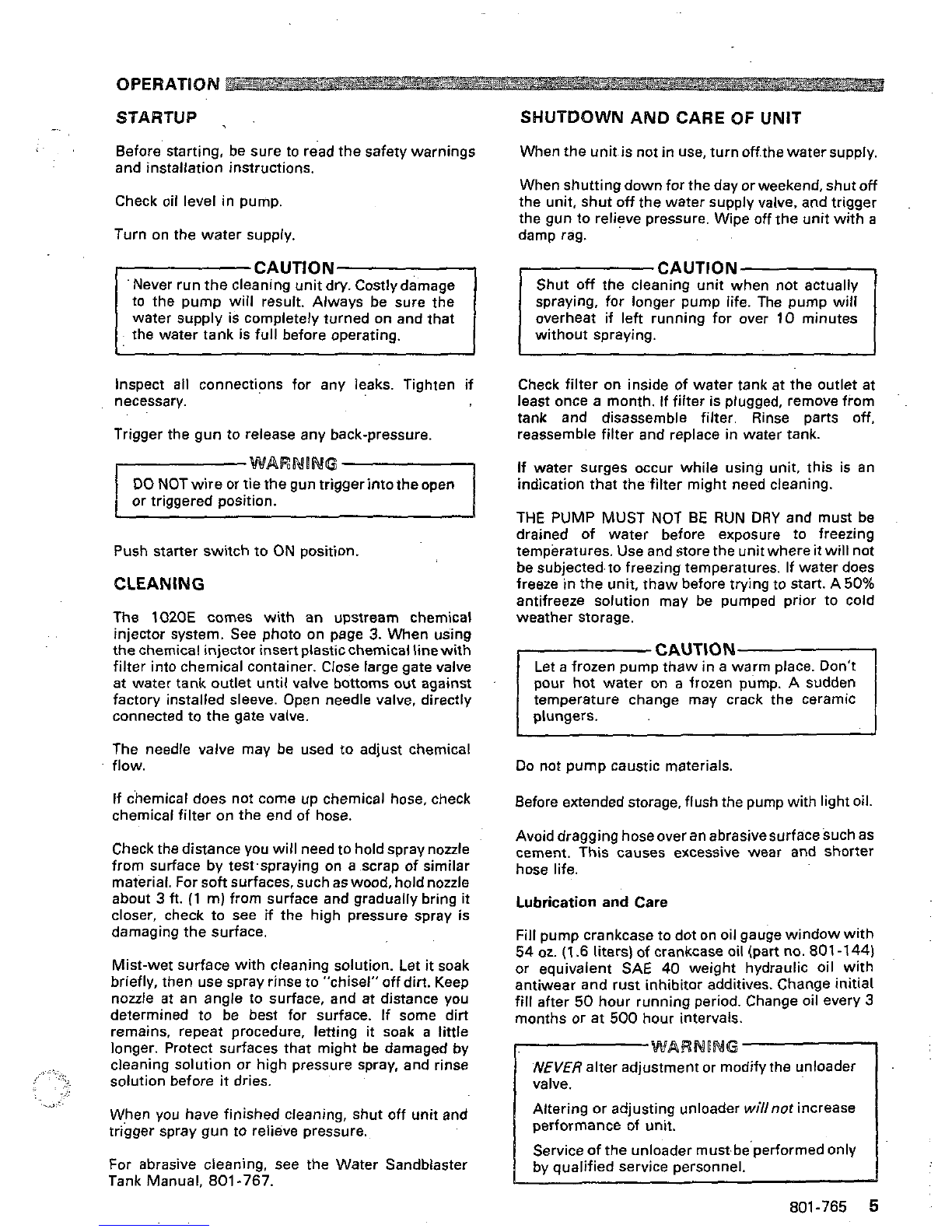

Before'starting, be sure to read the safety warnings

and installation instructions.

Check oil level in pump

Turn on the watersupply.

water supply is completely turned on and that

the water tank is full before operating.

necessary.

Inspect

all

connectionsforany leaks. Tighten if

Trigger the gun to release any back-pressure.

WARNUNG

or triggered position.

DO

NOTwireor tie the gun trigger into theopen

Push starter switch toON position.

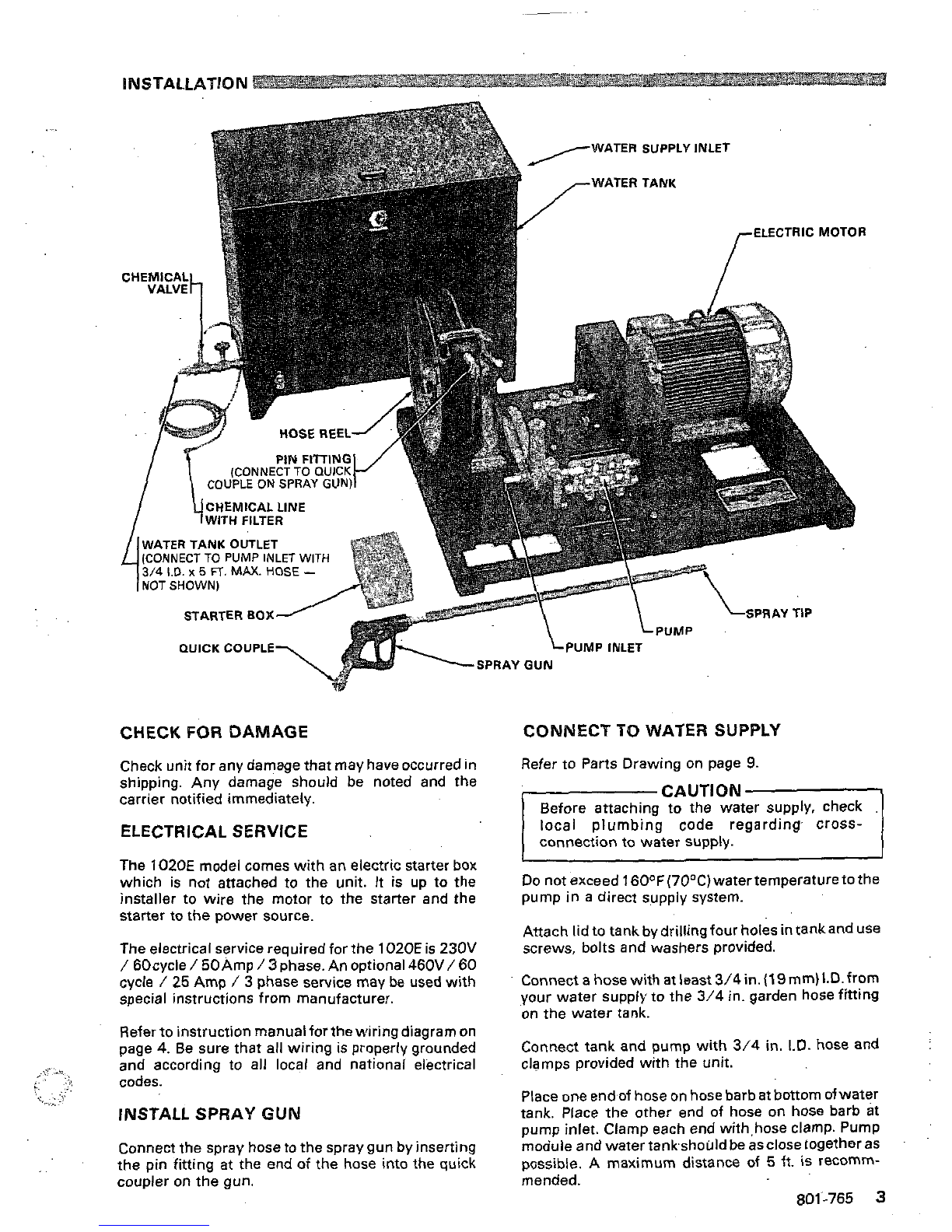

CLEANING

The

1020E

comes

with

anupstreamchemical

the chemical injector insert plasticchemical linewith

injectorsystem. See photo on page 3. When using

filter into chemical container. Close large gatevalve

factory installed sleeve. Open needle valve, directly

at water tank outlet

until

valve bottoms out against

connected to the gate valve.

Theneedlevalvemaybe used

to

adjustchemical

flow.

chemical filter on the endof hose.

If chemical does not come up chemical hose, check

Check thedistance you

will

need to hold spraynozzle

from surface by test.spraying on a scrap of similar

material. For soft surfaces, suchaswood, holdnozzle

closer,check to see

if

thehighpressurespray

is

about

3

ft.

(1

m) from surface

and

gradually bring

it

damaging the surface.

Mist-wet surface

with

cleaning solution. Let

it

soak

briefly, then use spray rinse to "chisel"

off

dirt.

Keep

nozzle

at

an

angletosurface,andatdistanceyou

determinedtobebestforsurface.Ifsomedirt

remains,repeatprocedure,letting

it

soak a little

longer.Protectsurfaces thatmightbe damaged by

solution before

it

dries.

cleaning solution or high pressure spray. and rinse

When you have finished cleaning, shut off

unit

and

trigger spray gun to relieve pressure.

Tank Manual,

801 -767.

Forabrasivecleaning,seetheWaterSandblaster

When the unit is not

in

use, turn off.the watersupply.

When shutting down for the dayor weekend,shut

off

the unit, shut

off

the water supplyvalve, and trigger

the gun to relieve pressure. Wipe

off

the unit

with

a

damp rag.

CAUTION

spraying,forlongerpumplife. The pump

will

overheatifleftrunningfor over

10

minutes

without spraying.

Check filter on inside

of

water tank at the outlet at

least once a month. If filter isplugged, remove from

tank and disassemble filter. Rinse parts

off,

reassemble filter and replace

in

water tank.

Ifwatersurgesoccurwhileusingunit,thisis

an

indication that the.filter might needcleaning.

THE PUMPMUST NOT

BE

RUN DRY andmustbe

drainedofwaterbeforeexposuretofreezing

temperatures. Use and store the unit where

it

will

not

be subjected. to freezing temperatures. Ifwater does

freeze

in

the unit,

thaw

before trying to start.

A

50%

antifreezesolutionmaybepumpedpriortocold

weather storage.

CAUTION

pour

hot

wateron afrozenpump.

A

sudden

temperaturechangemaycracktheceramic

plungers.

Do not pumpcaustic materials.

Before extended storage, flush the pump

with

light oil.

Avoid dragging hoseover an abrasivesurfacesuchas

cement,Thiscausesexcessivewearandshorter

hoselife.

Lubrication

and

Care

Fill pump crankcase to dot on oilgauge window

with

54

oz.

(1.6

liters)

of

crankcase oil(part no.

801 -144)

orequivalentSA€

40

weighthydraulicoil

with

antiwear and rust inhibitor additives. Change initial

fill after

50

hour runningperiod. Change oil every

3

months or at

500

hour intervals.

'N€V€/?

alter adjustmentor modify the unloader

Altering or adjusting unloader

willnot

increase

performance of

unit.

Service

of

the unloader must.be performed only

by qualified service personnel.

801-765

5