WWW.AIRLESSCO.COM TEL: 805-523-0211 FAX: 805-523-1063

WWW.AIRLESSCO.COM TEL: 805-523-0211 FAX: 805-523-1063

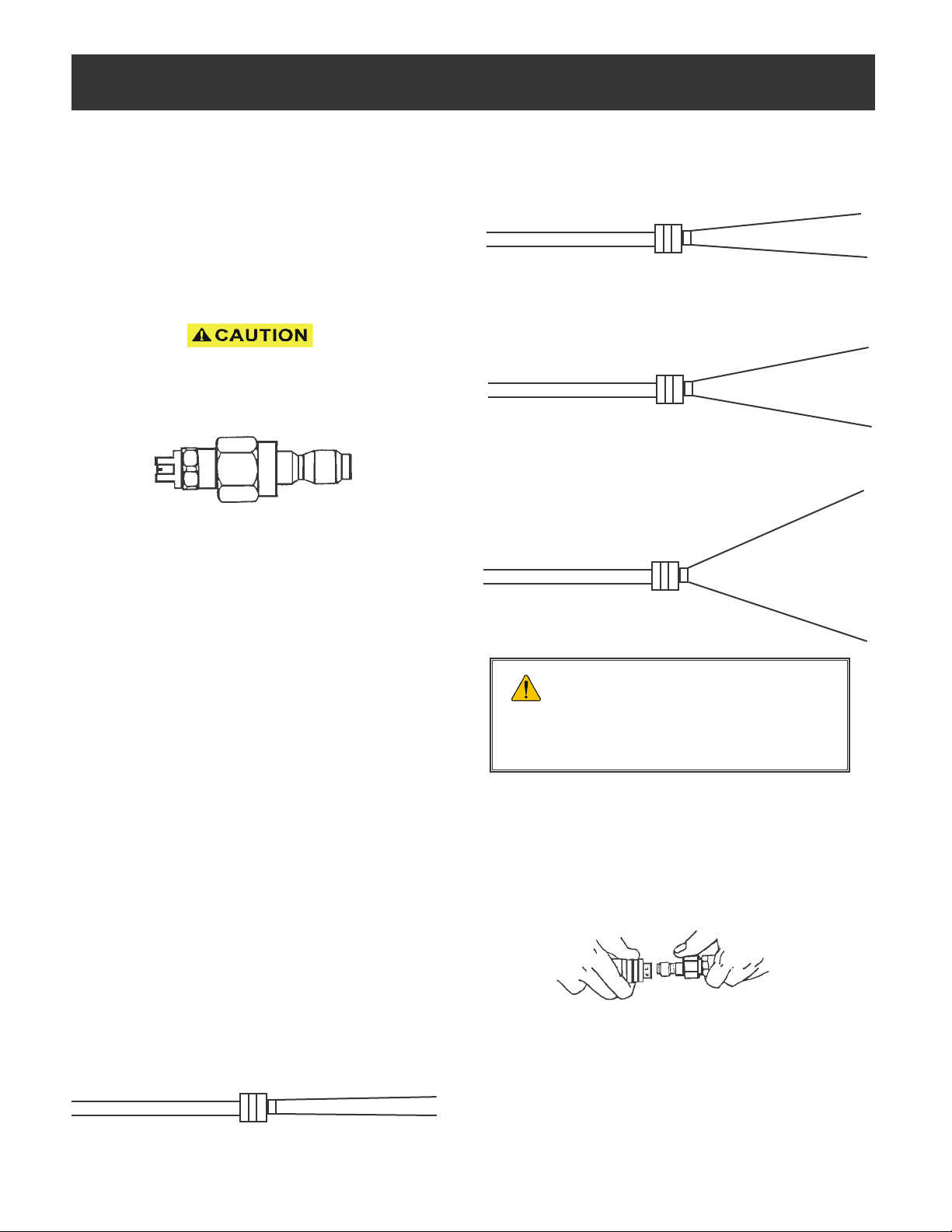

TIPS OR NOZZLES

The Quick Couplet Tips or Nozzles are inserted into the

end of the wand by means of a Quick Coupler. Tips are

supplied in the four most popular sizes & can do many

jobs for you. You MUST seat the tip into the quick coupler

rmly and make sure the quick coupler is closed. If you

have a leak at the tip around the quick coupler, you have

lost the O-Ring inside the quick coupler. If lost, the O-Ring

MUST BE REPLACED!

Failure to lock the quick coupler into place can result in

personal injury and loss of the O-Ring on a female coupler.

Danger signals are indicated by water leakage.

Learning what each tip can do for you will make your

AIRLESSCO machine more valuable and will allow you

to do your cleaning jobs faster and more effectively. By

experimenting, you will nd that different tips do the job

better and moving the wand closer to and farther from the

area to be cleaned will also change the way the machine

will work for you.

You should always start each new job away from the target

and move closer as you see the need. Be careful, you can

damage some surfaces if the pressure is too concentrated

and too close.

NOZZLE SELECTION GUIDE

The pressure and volume of a pressure washer is deter-

mined by the size of the opening (orice) in the nozzle.

There are numbers on the nozzle which explain it’s size.

The rst two numbers indicate the size of the spray angle.

(00 means 0 degree, 15 means 15 degrees etc…) The last

number indicates the size of the orice. This is not a mea-

surement of an inch, but a standardized measurement.

THE 0 DEGREE NOZZLE –

This is the blasting nozzle. It delivers a very concentrated

stream of water. Care should be used to avoid damaging

wood or fragile surfaces. WARNING: This nozzle must

not be used on rental machines supplied to homeowners or

non-contractors.

TIPS AND NOZZLES

THE 15 DEGREE NOZZLE – 3/4"

This is a chiseling nozzle. The spray should be directed at a

45 degree angle to the surface and used like a scraper to re-

move paint, grease and dirt. This is the most used tip of all.

THE 25 DEGREE NOZZLE – 5-6”

This is a ushing nozzle. It gives a wider coverage and is

used if the area being cleaned would be damaged by a nar-

rower tip.

THE 40 DEGREE NOZZLE – 8-10” –

This is a wash nozzle. Its wide spray pattern disperses the

water pressure over a large area and is recommended

for rinsing and moderate washing.

TIPS WILL WEAR IN TIME. THE MORE

YOU USE A TIP, THE MORE YOUR TIP

WILL WEAR. A WORN TIP WILL CAUSE A

SIGNIFICANT DROP IN PRESSURE. CHECK

AND REPLACE YOUR TIPS FREQUENTLY.

QUICK COUPLER

The quick coupler allows you to attach different devices to-

gether quick and secure. To use, simply slide the collar back

and insert the plug. Make sure the plug is securely seated.

It’s always a good idea to “tug” on the two parts to make

sure they are rmly seated together.

Always make sure the O-Ring is in place inside the quick

coupler. To see if the O-Ring is in place, make sure the Pres-

sure Washer is off and all system pressure has been relieved,

then you may look into the quick coupler at the collar (fe-

male) side of the quick coupler. You will be able to see the

O-Ring inside. If the O-Ring is missing, it must be replaced

to ensure a good pressure seal.

0°

15°

25°

40°

Socket Plug

7