FOR

PROFESSIONAL USE ONLY.

OBSERVE

ALL

WARNINGS.

Read

and

understand

all

instruction

manuals

before

operating

equipment.

EQUIPMENT MISUSE HAZARD

General Safety

Any misuse of the equipment or accessories, such

es

over-

pressurizing, modifying parts, using incompatible chemicals

and fluids, or using worn or damaged parts, can cause them to

rupture and result in serious bodily injury, such as splashing

fluid in the eyes or on the skin, fire, explosion, or propew

damage.

NEVER alter or modify any part of this equipment; doing

so

could cause

it

to malfunction.

damaged parts immediately.

CHECK all equipment regularly and repair or replace worn or

ALWAYS read and follow the fluid and solvent

manufacturer's literature regarding the use of protective

clothing and equipment.

System Pressure

This pump can develop

16

bar

(230

psi/ MAXIMUM

WORK-

ING

PRESSURE.

at

12.4

bar

(180

psi) MAXIMUM INCOM-

cessories are rated to withstand the maximum working

ING AIR PRESSURE. Be sure that all equipment and ac-

pressure of this pump. DO NOT exceed the maximum working

pressure of any component or accessory used in the system.

Fluid

Compatibility

BE

SURE that

all

fluids and solvents used ere chemically com-

the back cover. Always read the fluid and solvent manufac-

patible with the wetted parts shown in the Technical Data on

turer's literature before using them in this pump.

Pressure Relief Procedure

To

reduce the risk of serious bodily injury, including splashing

follow

this procedure whenever you shut

off

the pump, when

in the eyes or on the skin, or injury from moving parts, always

checking or servicing any part of the system. when installing,

cleaning or changing nozzles, and whenever you stop dispens-

Ing.

1.

Shut

off

the air to the pump.

2.

Close the bleed-type master air valve (required in your

system).

3.

Hold

a

metal partof the dispensing valve firmly to the side

of

a

grounded metal pail, and actuate the valve

to

relieve

4.

Open the drain valve (required

i?

your system), having

a

pressure.

5.

Leave the drain valve open until you are ready to dispense

container ready to catch the dramage.

again.

If

you

suspect that the nozzle or hose

is

completely clogged,

or that pressure has not been

fully

relieved after following the

steps above, VERY SLOWLY loosen the hose end coupling

and relieve pressure gradually, then loosen completely. Now

clear the nozzle or hose.

FIRE

OR

EXPLOSION HAZARD

Static electricity

is

created by the flow of fluid through the

pump and hose.

If

wefy

part of the equipment is not properly

grounded, sparking may occur, end the system may become

hazardous. Sparking may also occur when plugging in or

unplugging

a

power supply cord. Sparks can ignite fumes

from solvents and the fluid being dispensed, dust particlesand

other flammable substances, and can cause fire or explosion

and serious bodily injury and propew damage.

while using this equipment, STOP SPRAYING

IM-

If you experience any static sparking or even

e

slight shock

MEDIATELY.-Check the entire system for proper grounding.

tified and corrected.

Do not use the

syam

again until the problem has been iden-

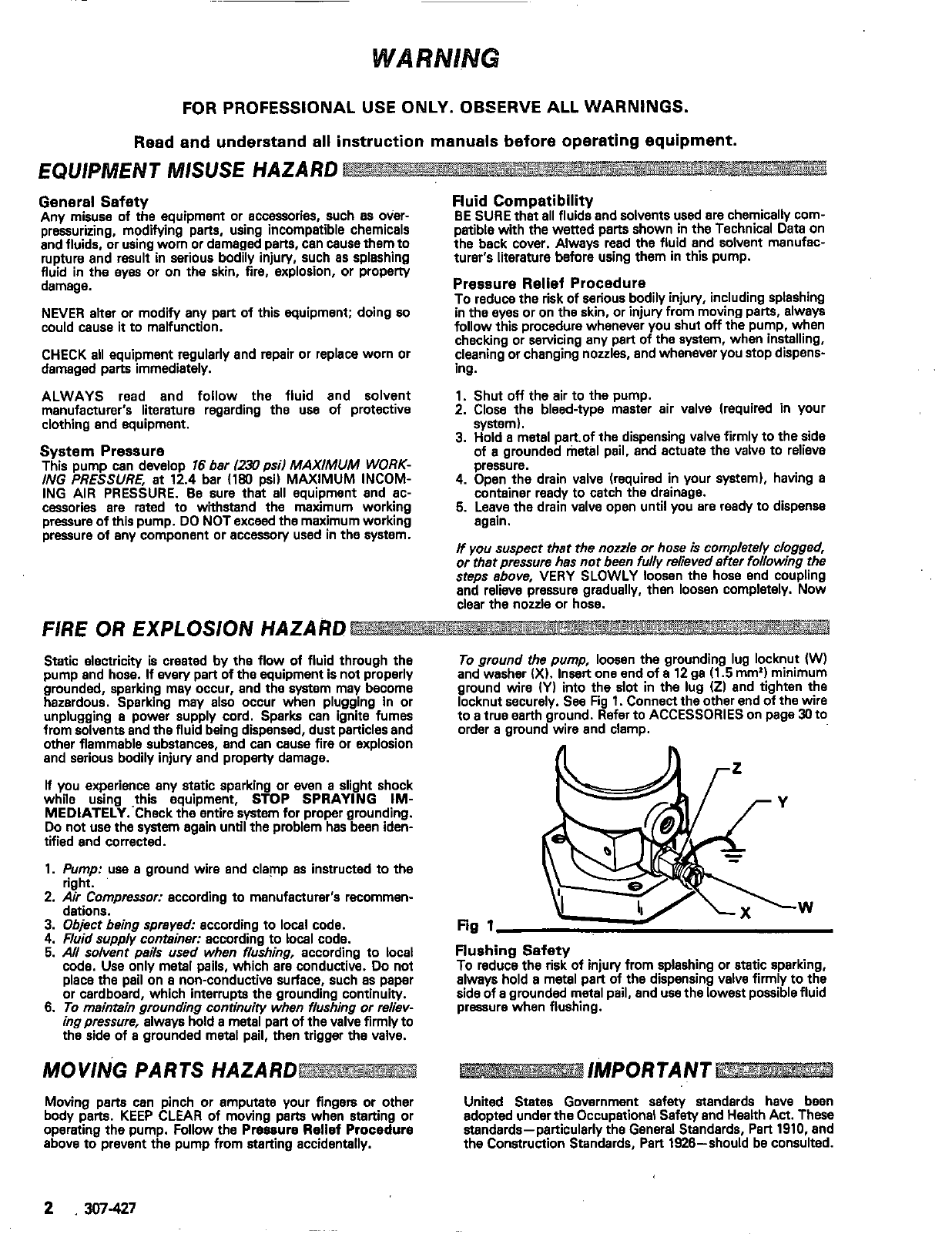

1.

Pump:

use

a

ground wire and clamp

as

instructed to the

2.

Air Compressor: according to manufacturer's recommen-

3.

Object being sprayed: according to local code.

4.

Fluid

supply container: according to local code.

5.

All

solvent pails used when flushing, according to local

code. Use only metal pails, which are conductive. Do not

place the pail on

a

non-conductive surface, such as paper

6.

To

maintain grounding continuity when flushing or re/iev-

or cardboard, which interrupts the grounding continuity.

ing

pressure, always hold

a

metal part of the valve firmly to

the side of

a

grounded metal pail, then trigger the valve.

right.

dations.

MOVING PARTS HAZARD

body parts. KEEP CLEAR of moving parts when starting or

Moving parts can pinch or amputate your fingers or other

operating the pump. Follow the Pressure Relief Procedure

above to prevent the pump from starting accidentally.

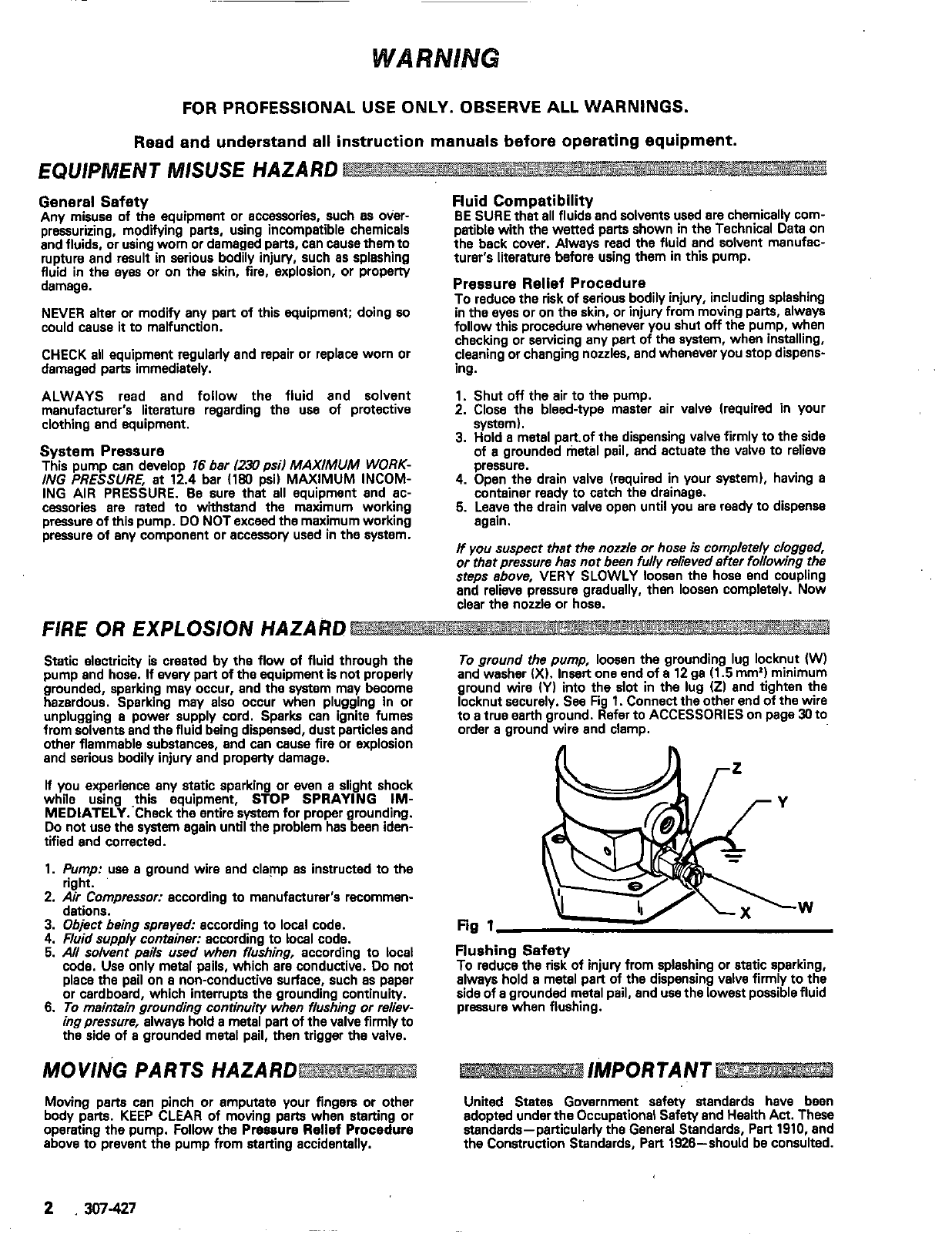

and washer

(X).

Insert one end of a

12

ga

(1.5

mm') minimum

To

ground the pump, loosen the grounding lug locknut (W)

ground wire (Y) into the slot in the lug

(ZI

and tighten the

to

a

true earth ground. Refer to ACCESSORIES on page

30

to

locknut securely. See Fig

1.

Connect the other end of the wire

order

a

ground wire and clamp.

Flushing Safety

To reduce the risk of injury from splashing or static sparking,

always hold

a

metal part of the dispensing valve firmly to the

side of

a

grounded metal pail, and use the lowest possible fluid

pressure when flushing.

IMPORTANT

United States Government safety standards have been

adopted under the Occupational Safety and Health Act. These

standards-particularly the General Standards, Part

1910,

and

the Construction Standards, Pert 1926-should be consulted.

2

,30747