!nstallation

Mountings A CEUTION

The pump exhaust air may contain contaminants

Ventilate to a remote area if the contaminants

could affect your fluid supply. See Air Exhaust'

Ventilation on page 8.

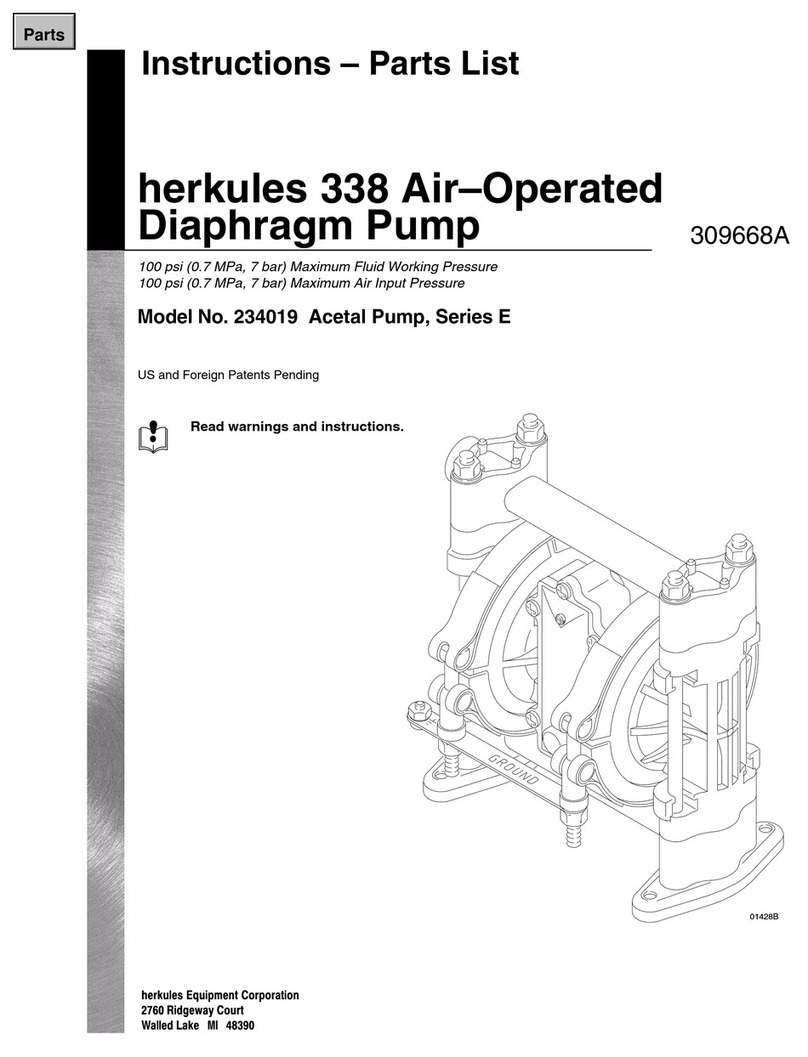

1. Be sure the mounting surface can support the'

weight of the pump, hoses, and accessories, as

well as the stress caused during operation.

2. For all mountings, be sure the pump is bolted

directly to the mounting surface.

3. For ease of operation and service, mount the

pump so the air valve cover (2), air inlet, and fluid

inlet and outlet ports are easily accessible.

4. Rubber Foot Mounting Kit 236452 is available to

reduce noise and vibration during operation.

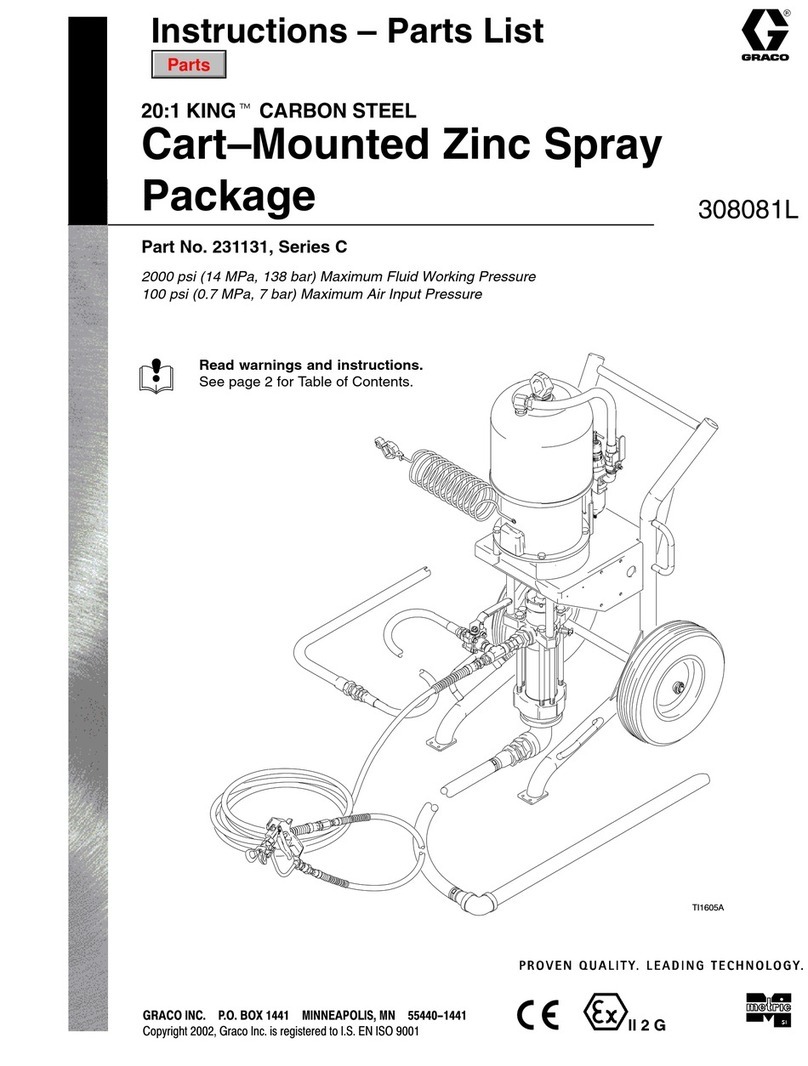

Air Line

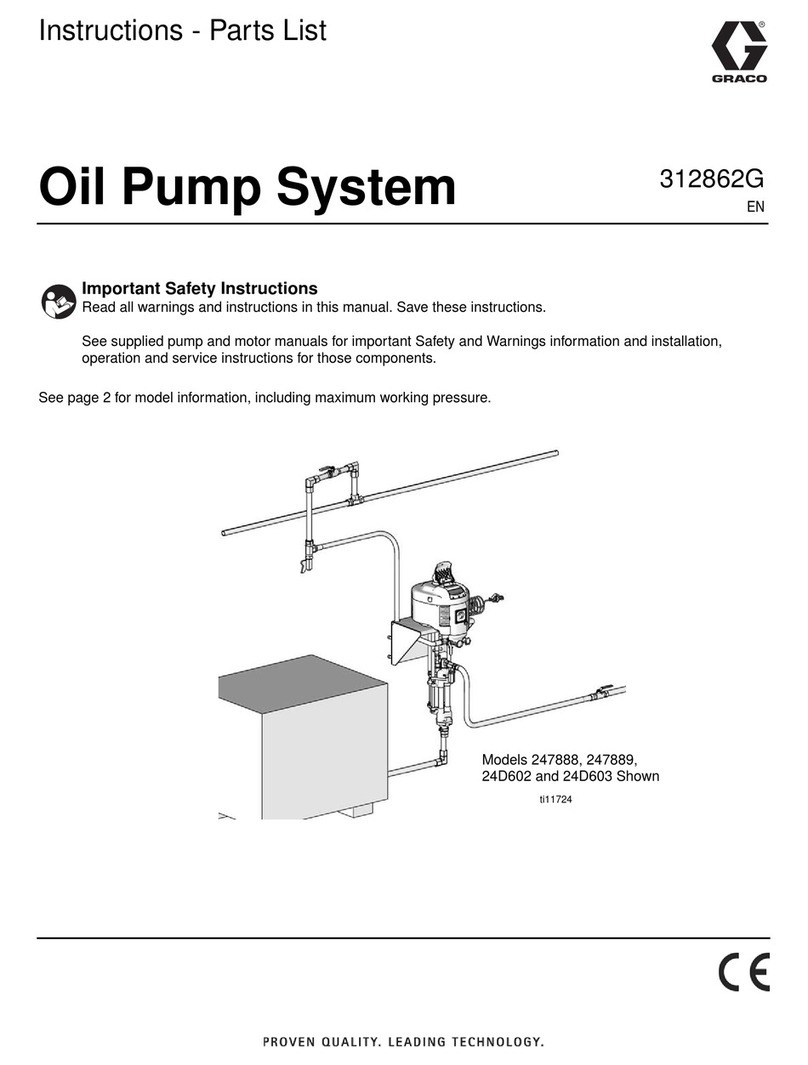

lnstall the air line accessories as shown in Figs.

24 on pages 6 and 7. Mount these accessories

on the wall or on a bracket. Be sure the air line

supplying the accessories is grounded.

a. lnstall an air regulator (C) and gauge to control

the fluid pressure. The fluid outlet pressure will

be the same as the setting of the air regulator.

b. '' Lbcate one bleed-type mlster air valve (B)

close to the pump and use it to relieve trapped

air. See the WARNING above. Locate the

other master air valve (E) upstream from all air

line accessories and use it to isolate them

during cleaning and repair.

c. The air line filter (F) removes harmful dirt and

. moisture from the compressed air supply.

2. lnstall a grounded, flexible air hose (A) between

the accessories and lhe 112 npt(f) pump air inlet

(N). See Fig.5. Use a minimum 3/8'(9.5 mm) lD

air hose. Screw an air line quick disconnect

coupler (D) onto the end of the air hose (A), and

. screw the mating fitting into the pump air inlet

snugly. Do not connect the coupler (D) to the fitting

until you are ready to operate the pump.

Fluid Suction Line

1. Use grounded fluid hoses. The pump fluid inlet (R)

is 1" npt(f). See Fig. 5. Screw the fluid fitting into

the pump inlet securely.

2. lf the fluid inlet pressure to the pump is more than

25o/o of lhe outletworking pressure, the ballcheck

valves will not close fast enough, resulting in

inefiicient pu mp operation.

3. At inlet fluid pressures greater than 15 psi (0.1

MPa, 1 bar), diaphragm life will be shortened. I

4. See the Technical Data on page 29 for maximum

suction lift (wet and dry)

Fluid Outlet Line

1. Use grounded fluid hoses (L). The pump fluid

outlet (S) is 1l npt(f). See Fig. 5. Screw the fluid

fitting into the pump outlet securely. i

.t''

2. lnstall a fluid drbin valve (J) near the fluid outlet.

See the WARNING above, and Figs. 24 on

pages 6 and 7.

3. lnstalla shutoff valve (K) in the fluid outlet line

A bleed-type master air valve (B) is required in

your system to'relieve airtrapped between this'

valve and the pump. Trapped air can cause the

pump to cycle unexpectedly, which could result in

serious injury, including splashing in the eyes or on

the skin, injury from moving parts, or contamination

from hazardous fluids. See Fig. 3.

WD

7

A fluid drain valve, (J) is required to relieve pres-

sure in the hose if it is plugged. The drain valve l

reduces the risk of serious injury including splash-

ing in the eyes or on the skin, or contamination I

from hazardous fluids when relieving pressure.'ln=

stall the valve close to the pump fluid outlet. See

Fig. 3.

IIIAENINTC

308-479 r 5