5

OPERATION

Pressure

Relief Procedure

T

o reduce the risk of serious bodily injury

, including

fluid splashing in the eyes or on the skin, or injury

from moving parts, always follow this procedure

whenever

you shut of

f the pump, when checking

or

servicing any part of the dispensing system, when

installing,

cleaning or changing nozzles, and when

-

ever

you stop dispensing.

1.

Shut of

f the dispensing valve.

2. Shut of f the bleed–type master air valve (re-

quired

in your system), on the main air line.

3.

Close the bleed–type master air valve

(supplied

with your pump).

4. Trigger

the dispensing valve to relieve pressure.

If you suspect that the dispensing valve, nozzle or

hose

is completely clogged, or that pressure has not

been fully relieved after following the steps above,

VERY

SLOWL

Y open the pump bleeder valve, hav

-

ing a container ready to catch the drainage. Leave

the

pump bleeder valve open

until you are ready to

dispense again. VER Y SLOWLY loosen the hose

end coupling and relieve pressure gradually , then

loosen

completely

. Now clear the nozzle or hose.

WARNING

Keep

hands and fingers away from the priming pis

-

ton

and pump intake during operation and whenever

the

pump is charged with air

. During operation, the

priming

piston extends beyond the intake housing

to

pull

material into the pump, and can severely injure

or

amputate a

hand or finger caught between it and

the

intake housing. Always follow the

Pressure Re

-

lief Procedure W arning above before checking,

clearing, cleaning, flushing or servicing any part of

the

pump.

The

air motor piston and fluid piston (located inside

the

air motor cylinder and coupling) also move when

air

is supplied to the motor

. Do not place your hand

or

fingers into the air motor coupling cavity while the

pump

is operating.

As the ram is raised and lowered, the wiper plate,

ram tubes, and pump mounting bracket move. T o

reduce

the

risk of pinching or amputation of fingers,

keep

your hands away from the

wiper plate, lip of the

fluid can, pump bracket and ram tubes while the

pump

is operating.

To reduce the risk of serious injury and damage to

equipment, DO NOT shut of f the air supply to the

ram

when the ram

is raised. Doing so will cause the

pump

to fall uncontrolled to the bottom.

WARNING

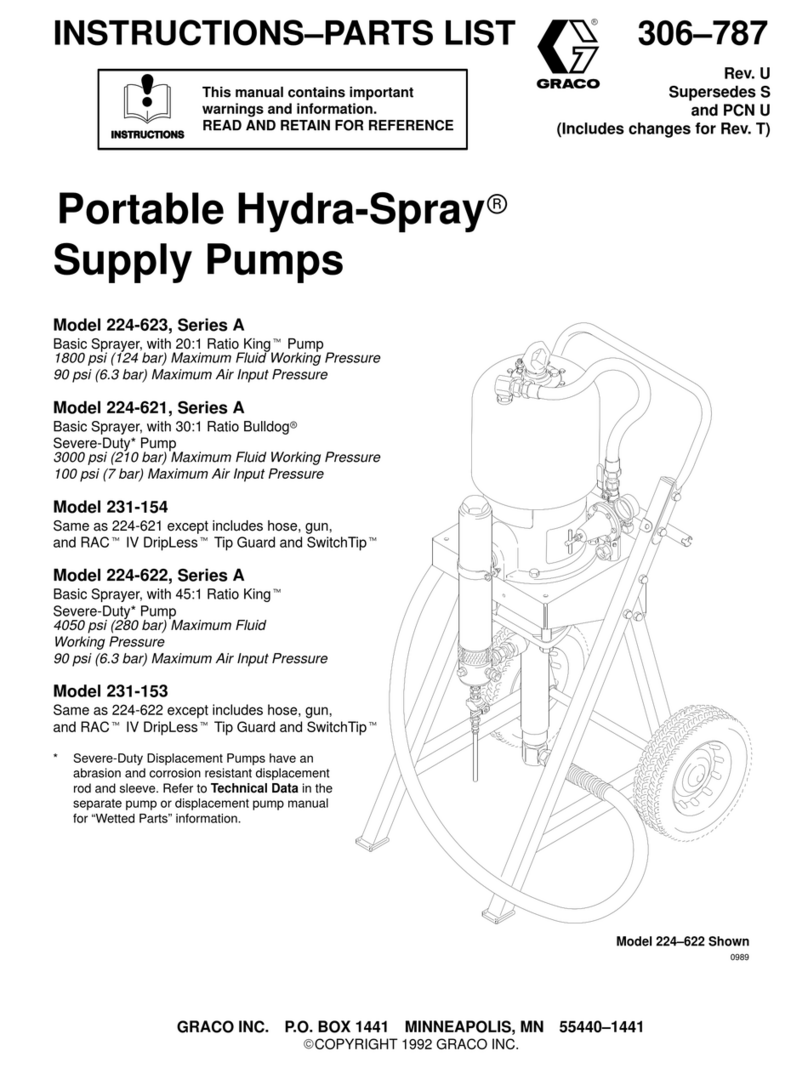

Starting and Adjusting the Ram

1.

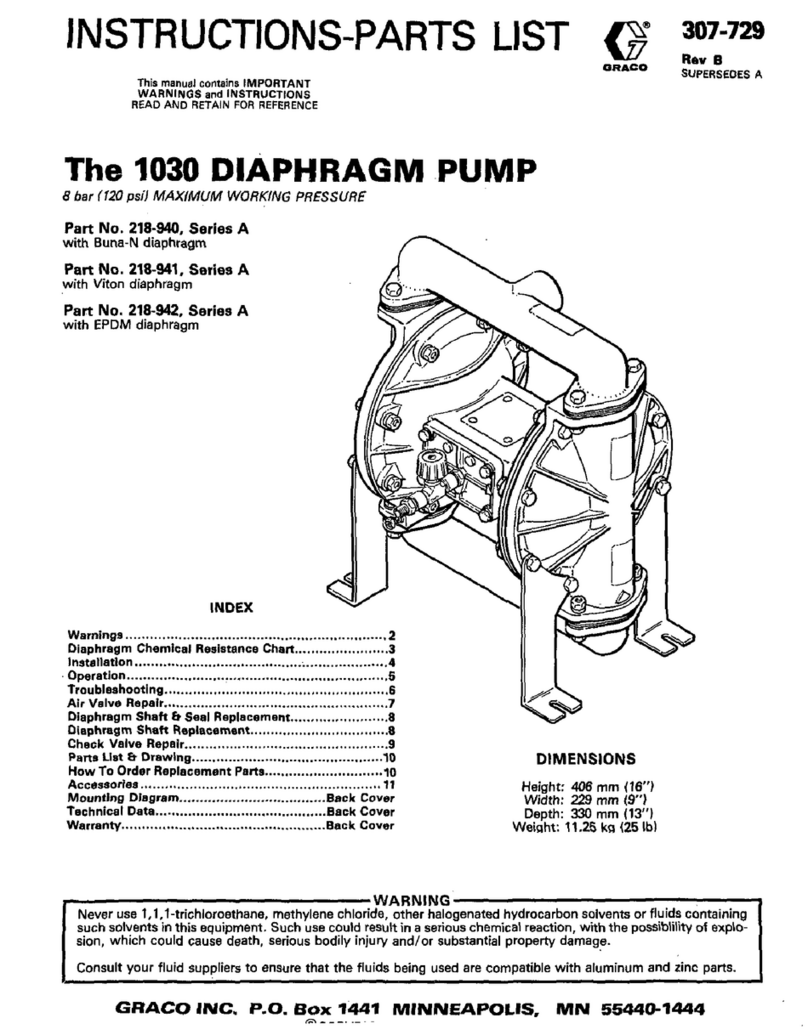

Refer to Fig 1. Be sure all air regulators and bleed–

type air valves are closed.

2. Open

the air valve

in the main air line and set the ram

air

regulator (227b) to 2 bar (28 psi). Set the ram di

-

rector valve switch (236) to the UP position and let

the

ram rise to its full height. T

o change the speed at

which

the ram raises and lowers, adjust the air regu

-

lator

to increase or decrease the air volume.

3. Check

that the fluid can is not dented or out of shape,

which

will damage the wiper plate

and cause leakage

around

the wiper

.

Cut of

f the top of the fluid can with

the

can opener

, or remove the bottom of the can. Be

sure

that the edge is free of burrs, which will damage

the wiper plate. If necessary , bend the edge back

with

a pliers so the wiper plate will enter the can easi

-

ly.

Lubricate the wiper

ring (305) to help the plate en

-

ter

the can easily

.

4. Set

a full can of fluid on the ram base, centering it un

-

der

the wiper plate (300).

5. Loosen

the wiper plate bleed valve (303) enough

to

allow air trapped under the wiper plate to escape.

With

your hands away from the lip of the can and the

wiper

plate, set

the director valve switch (236) to the

DOWN position and lower the ram until the wiper

plate

enters the can. Reduce the air pressure when

the plate enters the can.

NOTE: If the wiper plate does not enter the can easily ,

increase the ram pressure; once it enters the

can,

immediately reduce the pressure.

6. Continue to lower the ram until fluid appears at the

wiper plate vent hole. Tighten the wiper plate bleed

valve

(303) securely

. See Fig 1.

7. Clamp the can in place with the clamps (224) and

wing

screws (239), being sure the

clamp catches the

lip

of the can.

Priming the Pump and Pumping Fluid

1. Be

sure the pump air regulator (227a) is closed. Then

set

the ram air regulator (227b) to about 1.5 bar

(22

psi).

Set the director valve switch (236) to DOWN.

2. Open

the bleed–type master air valve (208). Set the

pump

air regulator (227a) to 2.0 bar (28 psi).

3. Open the pump bleeder valve (125) to allow air to

bleed

from the pump. When the pump is fully

primed,

close

the valve.

4. Keep the director valve switch (236) in the DOWN

position

while the pump is operating.

NOTE: Adjust

the air pressure to the ram as needed, but

DO NOT increase it to a level where fluid is

forced

past the wiper plate.

Changing Fluid Cans

1. Stop the pump. Close the bleed–type master air

valve (208), but leave air pressure on to the ram.

Open

the dispensing valve and relieve all fluid pres

-

sure

in the system.

2.

Set the director valve switch (236) to UP

.

3. Push in the air assist valve (218) and hold it in until

the

wiper plate clears the top of the can.

4. Loosen

the clamps (224) and remove the empty can.

Set

the full

can on the ram base and position it under

the

wiper plate.

5. Lower

the ram and adjust the position of the can rela

-

tive

to the wiper plate, as explained under

“Starting

and

Adjusting the Ram”.

Clamp the can in place.