2Grand Solar Inc. Blazing Tubes Manual

Page 2of 12 Grand Solar Inc. Blazing Tubes Manual

2) SYSTEM DESCRIPTION AND

OPERATIONAL PRINCIPLE

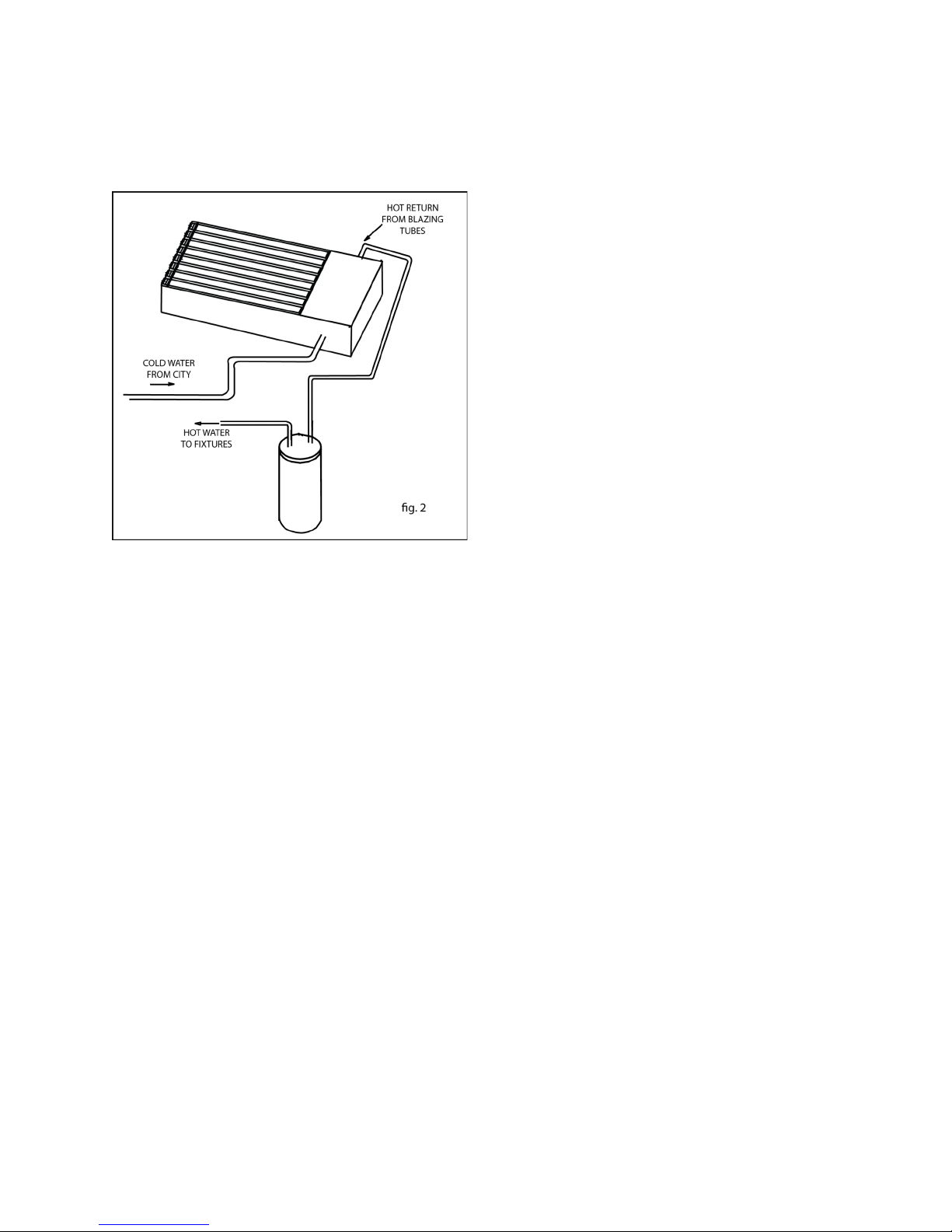

The Blazing Tubes is an integral collector stor-

age system. Systems combine the collector and

storage tank in a single roof-mounted unit. sys-

tems, in general, serve as pre-heaters for con-

ventional electric or gas water heaters. In some

parts of the world the Blazing Tubes may serve

as the sole water heater or will be used in con-

junction with a tankless, wall-mounted instanta-

neous gas water heater.

The Blazing Tubes also is referred to as a “pas-

sive” system because it does not require me-

chanical pumps, thermostats, sensors, wiring or

electricity to make hot water. Your Blazing

Tubes will neither freeze nor overheat during

prolonged periods of disuse if installed and main-

tained in accordance with the instructions con-

tained in this manual.

The inherent simplicity and durability of the Blaz-

ing Tubes makes it a popular choice for the con-

tinental U.S. Sunbelt or markets outside the U.S.

where persistent hard freezes do not occur.

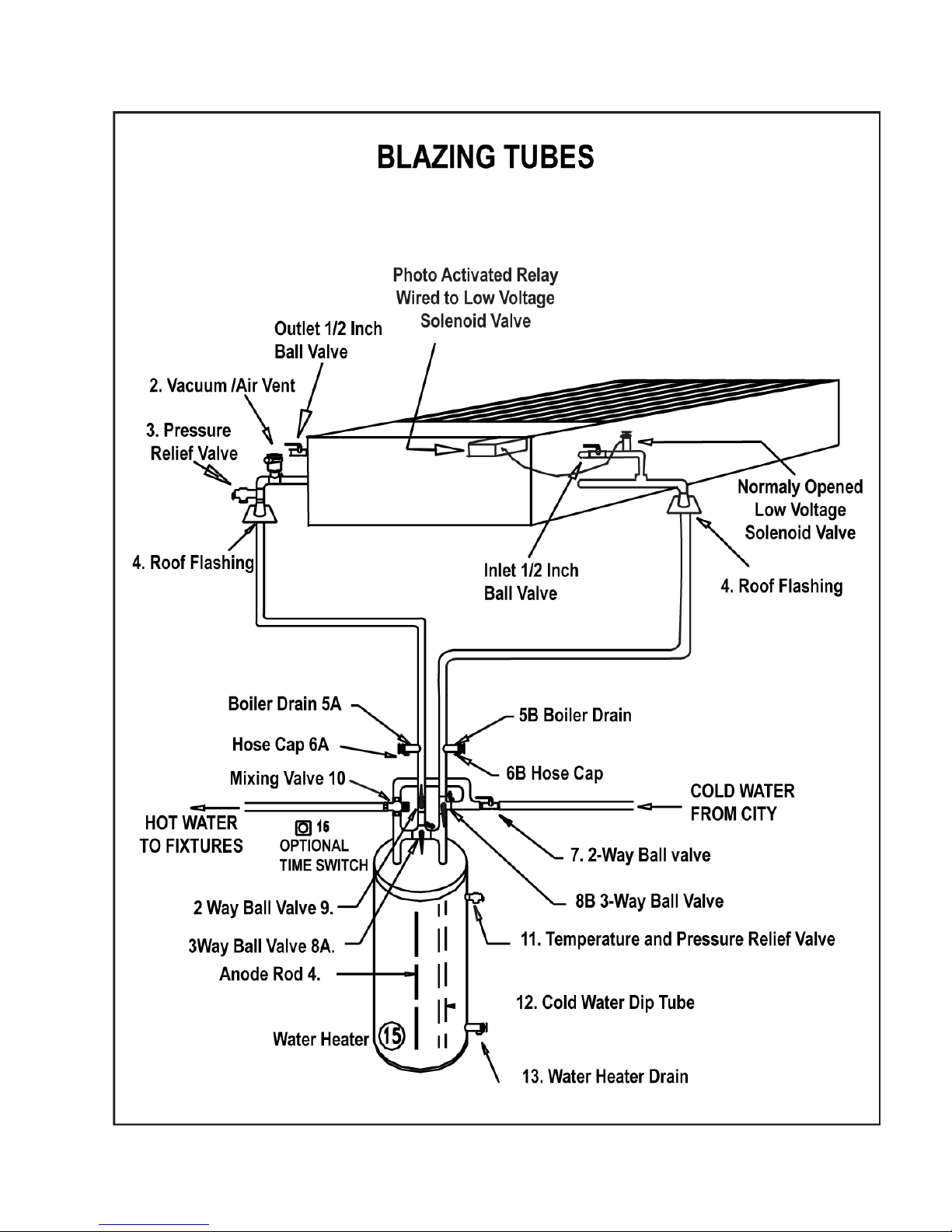

The Blazing Tubes System combines collection

and storage of solar heated water within eight 5”

glass vacuum tubes. Mechanically attached to

these tubes are eight EPDM boots, which house

eight copper heat exchangers, plumbed in se-

ries. Insulation surrounds these boots and their

internal heat exchangers, helping conserve the

heat collected by the glass tubes. These tubes

get filled with non-pressurized water, which acts

as a thermal battery for collected solar energy.

Pressurized domestic water flows though the

copper heat exchangers upon demand. Each

Blazing Tubes unit supplies 40 gallons of solar

hot water in a completely passive manner. The

Blazing Tubes system is used in conjunction with

any conventional gas, oil or electric water heater.

3) INSTALLATION

REQUIREMENTS -GENERAL -

A. Permits

The contractor shall obtain all required permits

and approvals.

B. Code

The installation shall conform to all federal, state

and local regulations, codes, ordinances and

standards governing solar water heating system

installations, and the contractor shall adhere to

sound building safety and trade practices. Spe-

cial consideration must be given to building code

requirements for roof loading and the penetration

of structural members and fire rated assemblies.

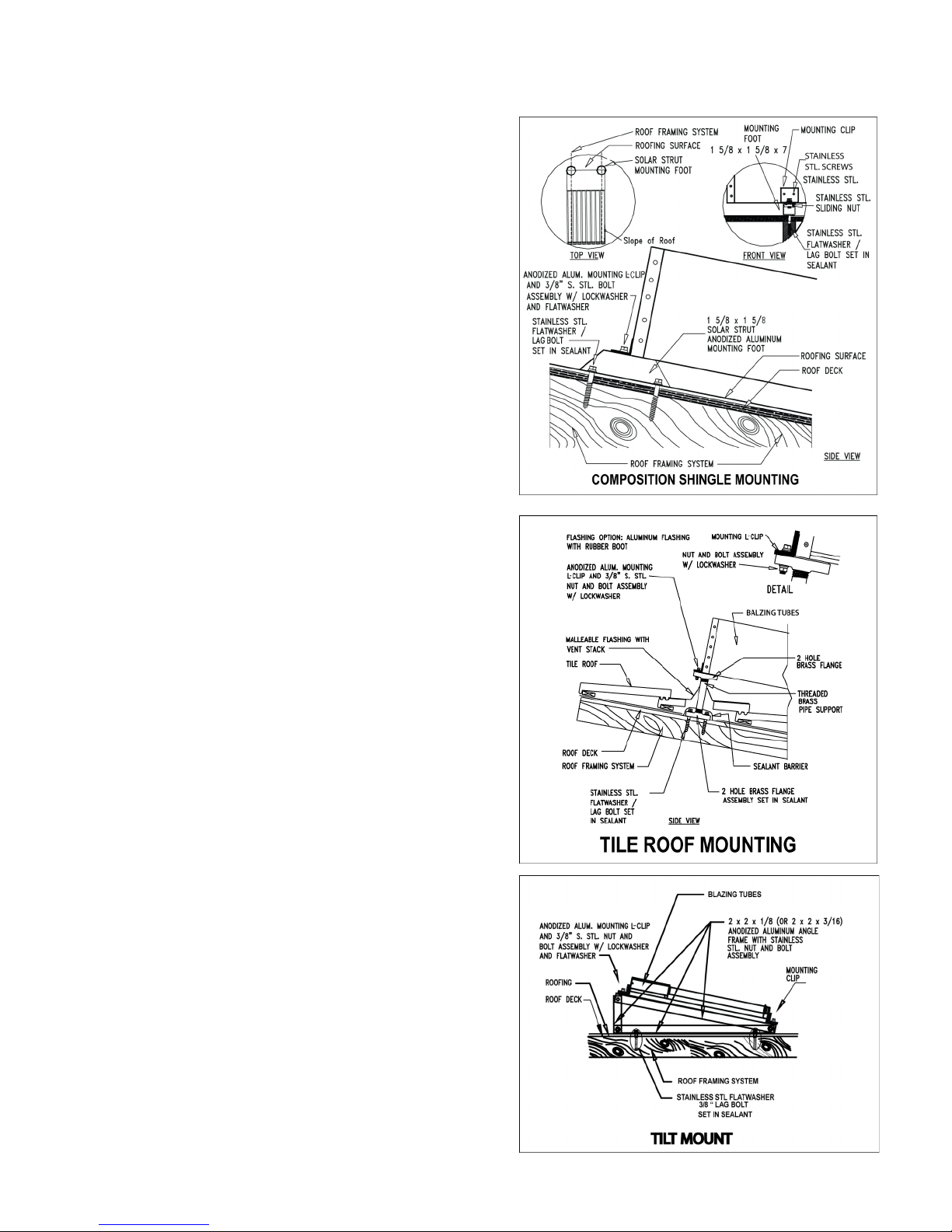

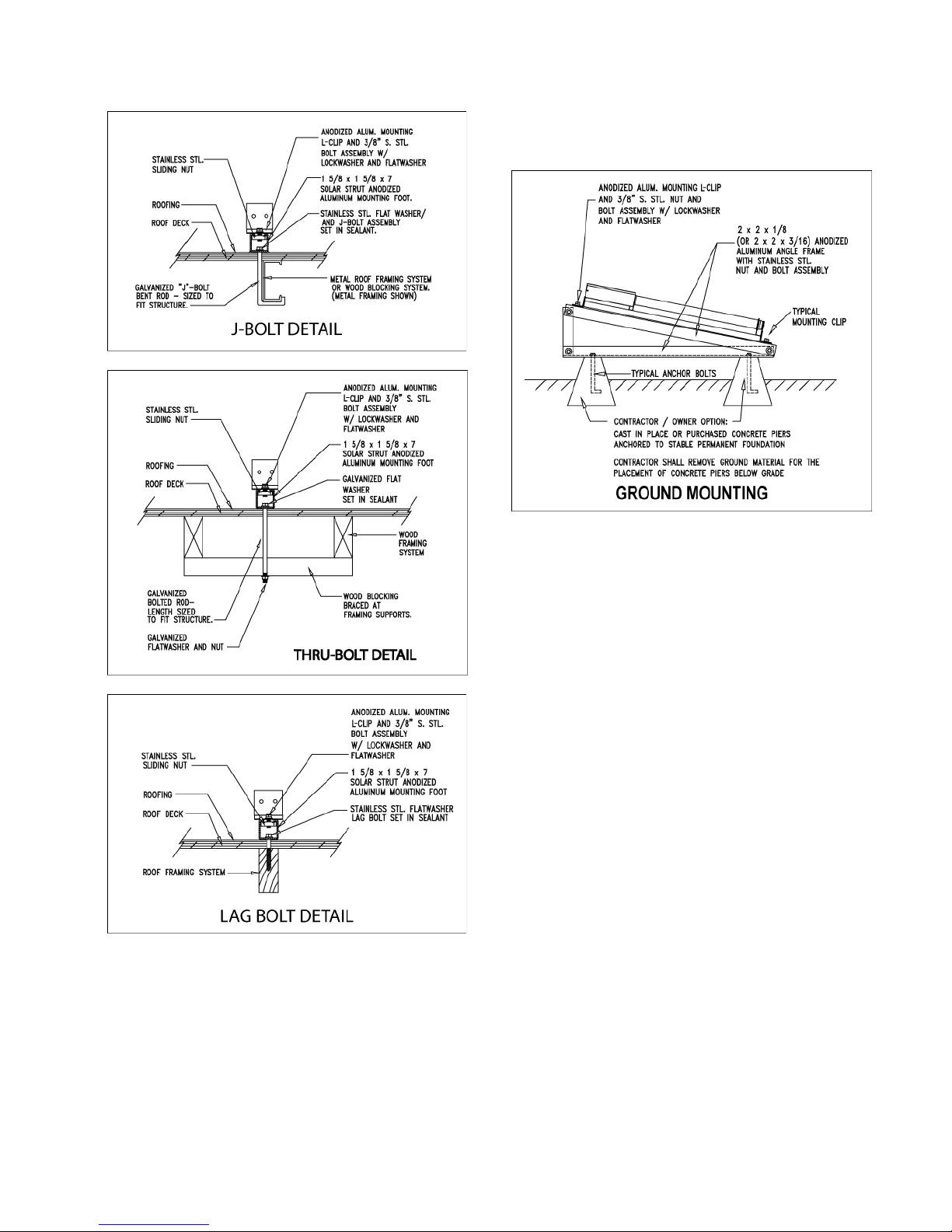

C. Structural & Shading Considera-

tions

The Blazing Tubes must be located in a structur-

ally sound area of the roof that will be unshaded

for the majority of the day all year round. Adja-

cent buildings and trees should be checked for

possible winter shading. An instrument such as

the Solar Pathfinder can be used for solar site

analysis. (Solar Pathfinder can be reached at

605-528-6473).

D. Roof and Site Inspection

Before the installation, the contractor shall in-

spect the condition of the roof and notify the

homeowner of any existing roof damage or nec-

essary repairs.

E. Confirmation of Installation Site

The homeowner and contractor shall confirm the

location of all roof and ground mounted compo-

nents in advance of the installation.