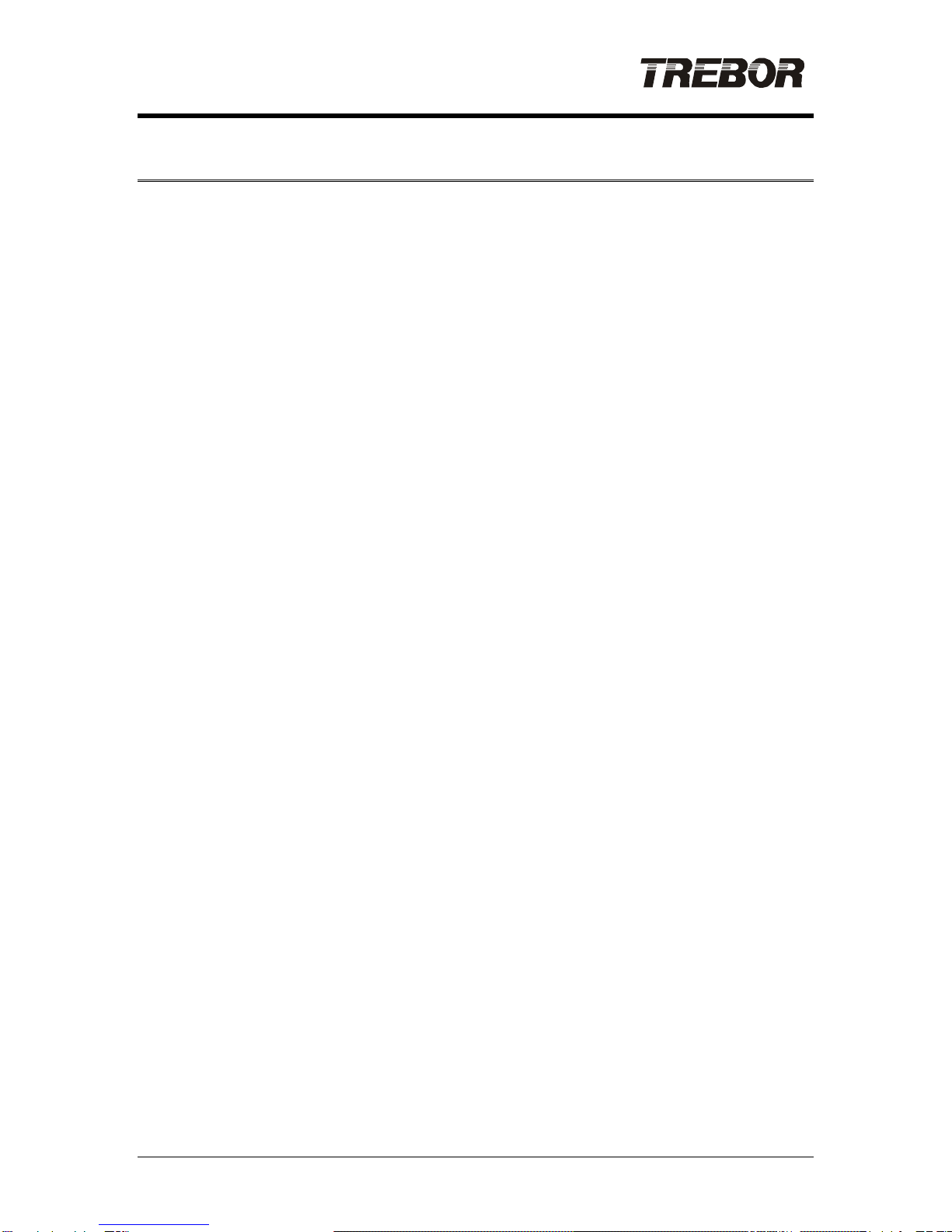

2472 DI HEATER OPERATION / MAINTENANCE MANUAL CONTENTS

CONTENTS

1INTRODUCTION........................................................................................................................3

2SAFETY .....................................................................................................................................4

2.1 SAFETY MESSAGE CONVENTIONS ............................................................................4

2.1.a Danger..............................................................................................................4

2.1.b Warning............................................................................................................4

2.1.c Caution .............................................................................................................5

2.2 EQUIPMENT SAFETY....................................................................................................5

2.3 INTERLOCKS.................................................................................................................5

2.3.a Over Temperature Controller Interlock (OTC) ..................................................5

2.3.b Low Pressure Switch Interlock..........................................................................6

2.3.c Liquid Level Sensor Interlock ...........................................................................6

2.3.d Panel Interlock Switches(is this section ok?)....................................................6

2.3.e Leak Sensor .....................................................................................................7

2.3.f Overpressure Burst Fitting................................................................................7

2.4 EMERGENCY OFF (EMO)..............................................................................................8

2.5 LOCKOUT / TAGOUT.....................................................................................................8

2.5.a Preliminary........................................................................................................8

2.5.b Definitions.........................................................................................................8

2.6 SEISMIC PROTECTION.................................................................................................9

3INSTALLATION .......................................................................................................................10

3.1 UNPACKING.................................................................................................................10

3.2LOCATION....................................................................................................................10

3.3 UTILITY REQUIREMENTS...........................................................................................11

3.4 HOOK-UP .....................................................................................................................13

3.5 REMOTE HOOK-UP.....................................................................................................16

4OPERATION ............................................................................................................................17

4.1 GENERAL.....................................................................................................................17

5START-UP ...............................................................................................................................19

5.1 PRE-START INSPECTION...........................................................................................19

5.1.a Verify Shipping Condition ...............................................................................19

5.1.b High Power Terminals ....................................................................................19

5.1.c Electrical Inspection........................................................................................19

5.1.d Plumbing Leak Check.....................................................................................19

5.2 SYSTEM ON.................................................................................................................20

5.3 TEMPERATURE CONTROLLER..................................................................................20

5.4 HEATER MODULE POWER.........................................................................................21

5.5 POWER DISTRIBUTION INDICATORS.......................................................................21

6SHUT DOWN ...........................................................................................................................22

6.1 HEATER CLEANOUT...................................................................................................22

7MAINTENANCE.......................................................................................................................23

7.1 REPAIR INSTRUCTIONS.............................................................................................23

7.1.a Heater Element Check....................................................................................23

7.1.b Fuse Replacement .........................................................................................23

7.1.c Draining the System .......................................................................................24

7.1.d Leaks..............................................................................................................24

7.1.e Overpressure Relief Replacement..................................................................25

7.1.f Heater Replacement.......................................................................................26

7.2 SPARE PARTS.............................................................................................................27

7.3 PREVENTIVE MAINTENANCE SCHEDULE................................................................27

7.4 HEATER CALIBRATION...............................................................................................28

8TROUBLESHOOTING.............................................................................................................31

8.1 TEMPERATURE CONTROLLER DOES NOT DISPLAY..............................................31

8.2 ALARM SOUNDS .........................................................................................................31

8.3 HEATER ELEMENT STATUS LED IS ON....................................................................32

9WIRING SCHEMATIC..............................................................................................................33

10 WARRANTY.............................................................................................................................34