CRF-1 Operating Manual Page 2 of 60 33801-V4 DMN S90

Contents

1. Introduction.....................................................................................................................6

1.1. Product Description....................................................................................................... 6

1.2. Product Accessories...................................................................................................... 6

2. How to use this Operating Manual ...............................................................................6

3. Safety Information..........................................................................................................7

3.1. CRF-1 Series Controlled Rate Freezer......................................................................... 7

3.2. Cryopen Nucleating Tool............................................................................................... 7

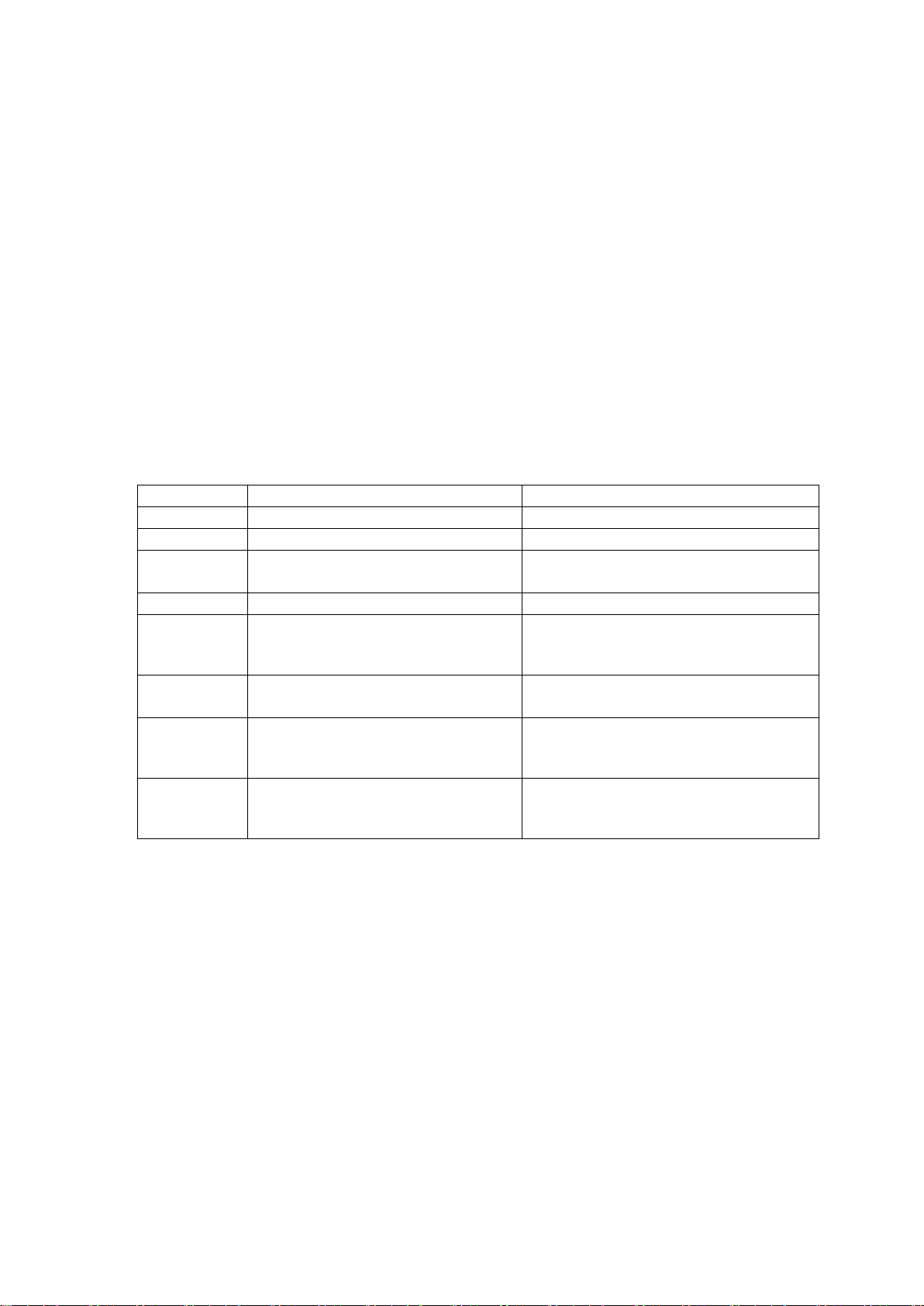

4. Technical Specification .................................................................................................8

4.1. Operating Conditions..................................................................................................... 8

4.2. Electrical Details............................................................................................................ 8

4.3. Models Available ........................................................................................................... 8

4.4. Performance.................................................................................................................. 8

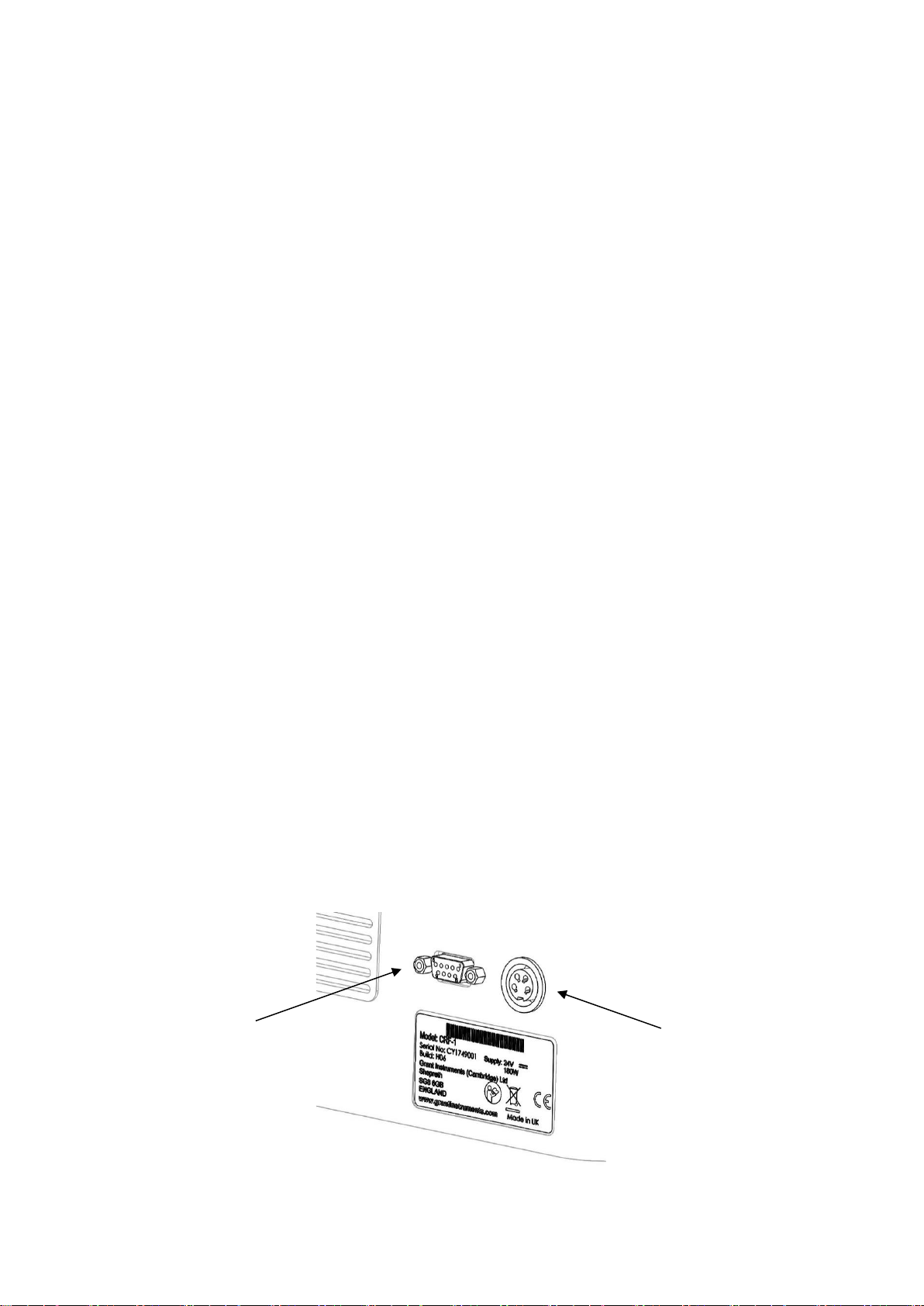

5. Installation.......................................................................................................................9

5.1. Unpacking ..................................................................................................................... 9

5.2. Freezer Position ............................................................................................................ 9

5.3. Electrical Connection..................................................................................................... 9

5.4. PC Setup..................................................................................................................... 10

5.5. Switching the Freezer On............................................................................................ 10

6. Grant CRF Software .................................................................................................... 11

6.1. Installation and set up ................................................................................................. 11

6.1.2. Logging in.................................................................................................................... 14

6.1.3. CRF-1 connection & synchronisation.......................................................................... 15

6.1.4. Software overview....................................................................................................... 15

6.2. Establishing communications with the freezer unit ..................................................... 16

6.3. Running a profile......................................................................................................... 18

6.3.1. Selecting the profile & details...................................................................................... 18

6.3.2. Running the profile ...................................................................................................... 19

6.4. Creating reports........................................................................................................... 19

6.4.1. Generating a run report............................................................................................... 19

6.4.2. Running a TSV log file conversion.............................................................................. 20

6.4.3. Generating an event log report ................................................................................... 21

6.5. Editing and creating profiles........................................................................................ 21

6.5.1. Editing an existing profile ............................................................................................ 22

6.5.2. Setting the parameters of a profile.............................................................................. 23

6.5.3. Saving & loading profiles............................................................................................. 26

6.5.4. Creating & restoring backups...................................................................................... 27

6.6. Designing and configuring reports .............................................................................. 29

6.6.1. User defined report header ......................................................................................... 29

6.6.2. Report template storage location ................................................................................ 31

6.7. Configuring the software ............................................................................................. 31

6.7.1. Log file configuration options ...................................................................................... 31

6.7.2. Report configuration options ....................................................................................... 33

6.7.3. Profile configuration options........................................................................................ 33

6.7.4. Event log configuration options................................................................................... 33

6.7.5. Format configuration options....................................................................................... 33

6.7.6. Communication configuration options......................................................................... 34

6.8. Users........................................................................................................................... 34

6.8.1. Creating new users ..................................................................................................... 34

6.8.2. Editing existing users .................................................................................................. 35

6.8.3. Deleting existing users ................................................................................................ 35

7. Operating Procedure for the CRF-1 Freezer............................................................. 36

7.1. Pre-operation Checks.................................................................................................. 36

7.2. Nucleating Tool Preparation........................................................................................ 36

7.3. Sample Preparation..................................................................................................... 36

7.4. Starting the Freezing Cycle......................................................................................... 39

7.5. Sample Nucleation ...................................................................................................... 39

7.6. End of Freezing Profile................................................................................................ 42

7.7. Stopping the Cycle and Generating a Report. ............................................................ 42