GRASEN GSCS75067A-T08 User manual

Luoyang Grasen Power Technology Co.,Ltd.

Luoyang Grasen New Energy Technology Co.,Ltd.

40kW DC Charger Manual

Luoyang Grasen Power Technology Co.,Ltd.

June,2019

Luoyang Grasen Power Technology Co.,Ltd.

Luoyang Grasen New Energy Technology Co.,Ltd.

Preface:

In order to enable you to use 40kW EV DC charger safely, you can remove it in time

when you encounter a fault, please read the instructions carefully before use.

The charger is suitable for lithium-ion power batteries, providing energy output not

greater than the rated power, and maintaining high output voltage and current

accuracy; the display is the most important man-machine interface for the charger.

Display the state of charge, battery pack status, fault status, etc.

The charger strictly implements IEC 61851-1-2010 (Electric Vehicle Conductive

Charging System-Part 1: General Requirements) DIN SPEC 70121-2014-en (Electric

Vehicle-Hybrid Charging System, Electric Vehicle Charging Station for Controlling DC

Charging Digital communication with electric vehicles)

This manual is only applicable to 40kW series EV DC charger. The content of the

manual will be updated without any notice with the upgrade of control software and

display interface software.

Please keep the instruction manual for future reference.

Luoyang Grasen Power Technology Co.,Ltd.

Luoyang Grasen New Energy Technology Co.,Ltd.

Content

Operating Conditions and Safety Matters................................................................................................3

1. Overview............................................................................................................................................... 4

1.1 Function Description.......................................................................................................................4

1.2 Appearance Instruction.................................................................................................................. 4

1.2.1 Operational Zone..................................................................................................................... 4

1.2.2 Charging Connection Device....................................................................................................5

1.3 Main Technical Parameter..............................................................................................................5

2.Method of Application...........................................................................................................................6

2.1 Installation Instruction....................................................................................................................6

2.1.1 Structure Installation............................................................................................................... 6

2.1.2 Electrical Installation Instruction............................................................................................. 8

2.1.3 Outline Dimension Drawing.....................................................................................................9

2.2 Power-On Preparation..................................................................................................................10

2.2.1 Requirements for the Operators........................................................................................... 10

2.2.2 Inspection Matters before Use..............................................................................................10

3.Equipment Storage and Maintenance Instruction........................................................................10

3.1 Charger Storage.........................................................................................................................10

3.2 Charger Maintenance............................................................................................................... 11

4. Warranty............................................................................................................................................. 15

3

Luoyang Grasen Power Technology Co.,Ltd.

Luoyang Grasen New Energy Technology Co.,Ltd.

Operating Conditions and Safety Matters

(1) Operating Environment

Working temperature: -20℃~50℃;

Working Humidity: 5%~95%;

Atmospheric Pressure: 80kPa~110 kPa

(2) Safety Matters Instruction

1) Charger should be operated according to operation instruction provided by Luoyang

Grasen Power Technology Co.,Ltd.

2) Non professionals are forbidden to open charger cabinet and dismantle screen

touch without permission, sharp objects are forbidden to operate on the screen.

3) If there is stop halfway, first click “stop” button manually,then pull out charging

connector. Forbid inserting and pulling out charging connector directly during charging,

otherwise charging connector and charger will be burnt out and even the operators will get

burnt.

4) Any operation irrelevant to charging during the charging is forbidden.Other

operations should be done after clicking “stop” button on the charger and charging connector

disconnects with the vehicle.

5) Under urgent circumstances,press red emergency stop button on the charger and

cut down charger internal power supply.

6) Smoke and fire is forbidden around the charger and pay attention to ventilation.

7) The fuse must be replaced with the same type fuse and can’t be replaced by

copper and iron wire.

4

Luoyang Grasen Power Technology Co.,Ltd.

Luoyang Grasen New Energy Technology Co.,Ltd.

8) When there is high voltage or default, it should be repaired by professionals in risk

of danger.

9) Charger upper circuit breaker and power distribution cabinet should be

chosen,installed and operated by professional electricians;

10) It is recommended to turn off the power under severe weather such as

thunderstorm. If there is water accumulation in the charger, please contact the

manufacturer's personnel to deal with it before using it.

11) Charging cable unit weight is heavy,longer cable is easy to drag and under force,

adding the risk of cable twist,bump to and influence product service life. Therefore, pulling

hard and twisting charging cable is forbidden. Charging cable must not be twisted to make

charging socket under force when charging.

12) When inserting or pulling out charging connector, shaking the charging connector

is forbidden and it must insert or pull out with vertical force.

If the following conditions occur,please cut down the power in time and inform the

professionals for maintenance.

Abnormal sound inside the charger

Abnormal sound inside the charger

Abnormal smell or smoke inside the charger

No indication or responsive in charger display screen

An unrecoverable failure alarm in charger

Notice:Before power-on operation, please ensure good connection between device

shell and ground, otherwise there is danger of electric shock.

5

Luoyang Grasen Power Technology Co.,Ltd.

Luoyang Grasen New Energy Technology Co.,Ltd.

1.Overview

1.1 Function Description

This integrated DC charger can realize single connector fast charging, fast feed as well

as two connectors equal power charging at the same time.

1.2 Appearance Instruction

1.2.1 Operational Zone

Operation zone includes indicator, display screen, card reader zone and emergency

stop button. Indicator can show power supply, charging connector and fault status, display

screen is used for showing charging information, card reader zone is used for identifying

charging card and providing simple operation instruction, emergency stop button is used for

cutting off power supply under emergency situation to avoid accidents and normal outrage is

not suggested to use.

1-1 Charger Operational Zone Diagram

1.3 Main Technical Parameter

Serial

No.

Technical Index

Name

Technical Index

Content Remarks

1Input cable voltage 380V+15%

2Input Voltage Type Three Phase AC Three phase five wire

system

6

Luoyang Grasen Power Technology Co.,Ltd.

Luoyang Grasen New Energy Technology Co.,Ltd.

3AC Grid Frequency 50Hz±10%Hz

4 Output Voltage 200—750V Continuous adjustable

5Output Current 0—66.6A

Above 600V, constant

power, continuous

adjustable, stable output

6 Rated Output Power 40kW Above 600V,meet

constant power output

7Output Voltage Error ≤0.5%Full output range

8 Output Current Error

Output current≥30A:≤±1%

Output current<30A:≤±0.3A Full output range

9Stabilized voltage

precision ≤0.5%Full output range

10 Stabilized current

precision ≤0.5%Full output range

11 Ripple factor ≤0.5%Full output range

12 Average efficiency ≥94% Load at 50% and above

13 Power factor ≥0.99 Load at 50% and above

14 Leakage current ≤10mA

15 Power frequency

withstand voltage 2500VAC 1 min no insulation

breakdown and flashover

16 Insulation resistance ≥20MΩ Test voltage 1000VDC

17 Noise ≤60dB

18 Protection IP54

19 Cooling Method Air Cooling

2. Method of Application

2.1 Installation instruction

2.1.1 Structure installation

(1)Foundation drawing

40kW charger adopts ground installation and the installation should be reliable and

fastened, the following foundation is suggested:

7

Luoyang Grasen Power Technology Co.,Ltd.

Luoyang Grasen New Energy Technology Co.,Ltd.

2-1 Foundation Drawing

(1)Dismantle Instruction

(2) When installing, dismantle the cabinet wooden box pallet, remove the protection

plate,use the forklift to move the charger cabinet to the ground , then fasten the cabinet on

the abutment with bolt washer and nut, then put the protection plate back to the original

location.

2-2 Dismantling Instruction

Back

Left

Right

Charging pile operation face(front)

Embedded 4-M12 bolts,

installation size 475x230(mm)

inlet hole

Waterproof cover

M12 nut

Ø12 washer

M12 bolt

Protection

plate 1

Protection

plate 2

8

Luoyang Grasen Power Technology Co.,Ltd.

Luoyang Grasen New Energy Technology Co.,Ltd.

Installation Notes:

Drainage measures should be made at charger installation location to avoid charger

immersion to affect normal usage.

When installation,it should guarantee charger left and right side within 2 meters

without obstacles to ensure the charger heat dissipation and there should be enough

distance for easy operation in front of charger.

After fastening cabinet on the foundation, its installation vertical inclination should be

less than 5%, when fastening, nut tightening torque suggested is 28.5N·m.

Operation site should avoid direct sunshine and outside shade(rain-proof) shed

should be added.

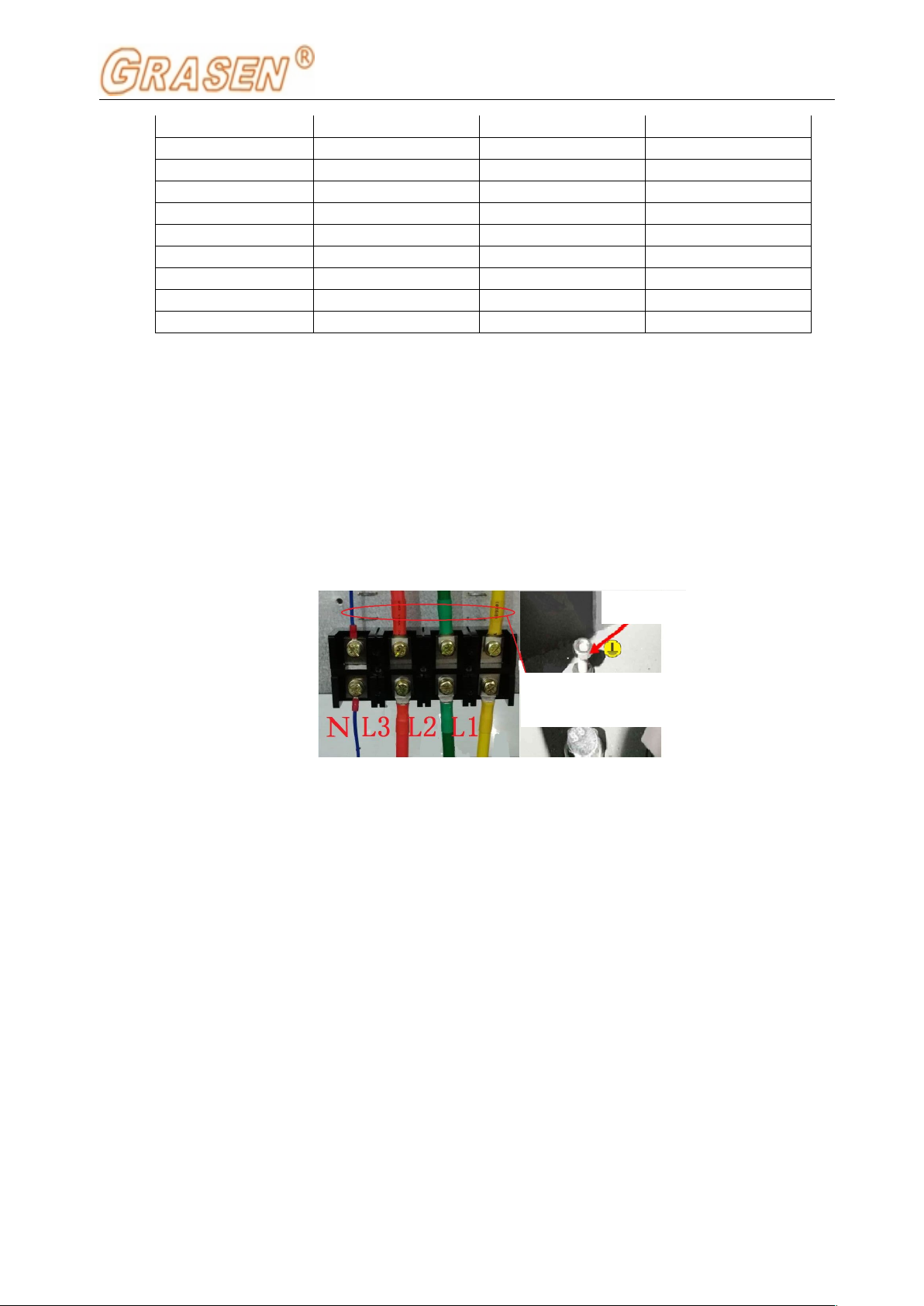

2.1.2 Electrical Installation Instruction

DC charger electrical installation must be done by the professional technician

and the charger input adopts three phase five wire system AC power supply,

maximum input current:77A, the cable and inlet terminal specification is as below:

Cable

Specification Inlet Terminal

YJV-3*16+2*10 SC16-6×3+SC10-6×2

Copper cable in accordance with GB 50217 and GB/T 12706.1 is recommended, adopting

terminal compression which matches with cable section, the exposed part of terminal joint

adopts heat shrinkable sleeve or insulation tape for insulation protection.

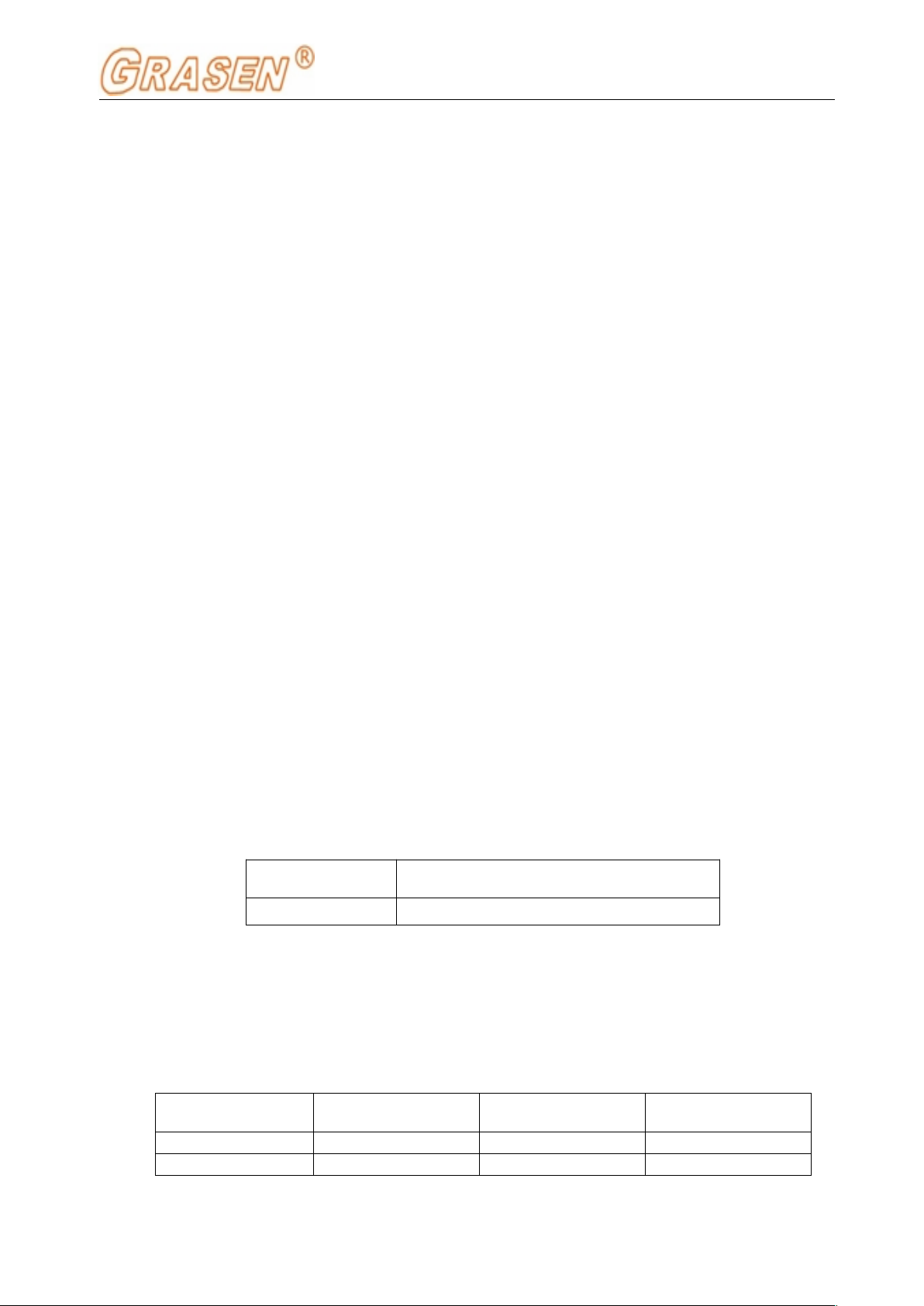

Requirement for tensile strength of compression terminals of every size is as below:

Conductor Size

(mm2)

Pressure Tensile

Strength(N)

Conductor Size

(mm2)

Pressure Tensile

Strength(N)

0.13 (AWG#26) 13 30 2300

0.2 (AWG#24) 22 38 2500

9

Luoyang Grasen Power Technology Co.,Ltd.

Luoyang Grasen New Energy Technology Co.,Ltd.

0.3 (AWG#22) 36 50 2900

0.5 (AWG#20) 58 60 3200

0.75 (AWG#18) 89 80 3500

1.25 200 100 3900

2 290 125 4000

3.5 540 150 4100

5.5 780 200 4400

8 980 250 4600

14 1400 325 4800

22 1800

If the conductor size used is not included in the table, it can choose appropriate

size corresponding tensile strength for test.

AC inlet is from charger bottom into charger, to AC input terminal and ground

terminal inside the charger. AC input must be connected according to inlet notes, the

zero line and phase can’t be connected reversely, otherwise leading to charger

unrecoverable fault.Charger upper breaker and distribution panel is chosen and

operated by professional electricians, torque 24N· m is suggested by electrician for

installation.

2-3 Electrical Wiring Diagram

Notice:First dismantle the terminal baffle when connecting the wire, then tighten the

terminal screw with socket wrench, it is forbidden to use screwdriver for operation

2.1.3 Outline Dimension Drawing

Inlet ground screw

Insulation heat shrinkable

sleeve

Table of contents