7

WORK SAFELY - FOLLOW THESE RULES

CAUTION

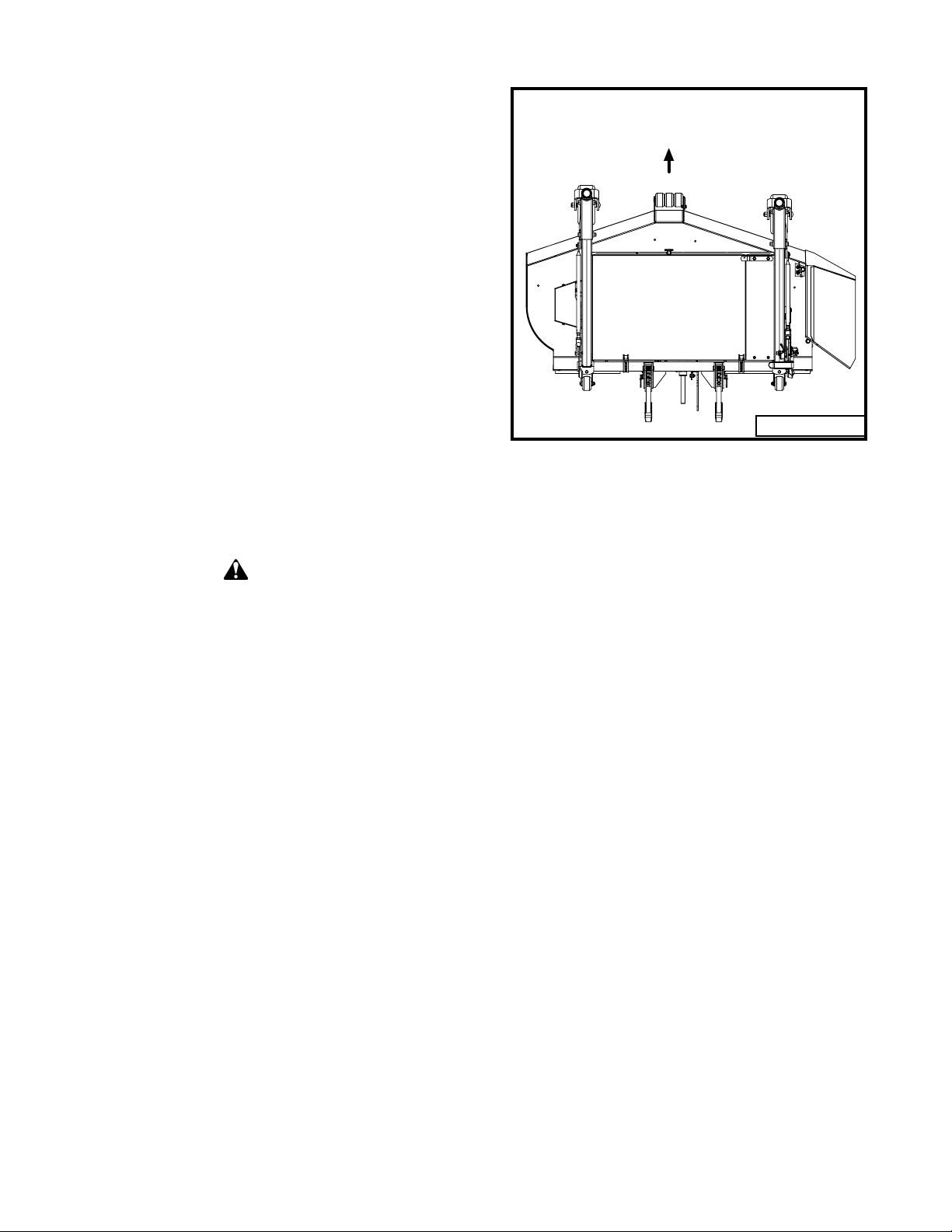

accessory installation instructions).

Inspect area to be cut and remove stones,

branches and other debris that might be

thrown causing injury or damage.

Never permit any person, other than the op-

erator, to ride or board the tractor or

implements at any time.

Operate only in daylight or good artificial

light.

OPERATIONAL SAFETY

Read “Operation” section of this manual be-

fore attempting to operate this unit.

Fenders serve as shields. Do not operate

without them.

Keep bystanders away from equipment

while it is in operation.

Keep children and pets a safe distance away.

Never direct discharge toward anyone if dis-

charge shield is installed.

Start engine from operator’s seat after disen-

gaging tractor power takeoff and placing

steering levers into the neutral swing-out

position.

Keep hands and feet away from underneath

mower while engine is running. Stay clear of

all moving parts on tractor and attachments.

If your tractor is equipped with a ROPS

(Roll-Over Protective Structure), you must

wear your seat belt.

Protect against noise. Wear suitable hearing

protection devices to protect against objec-

tionable noise.

Never allow anyone behind tractor or in

front of implements when operating.

Do not operate in reverse unless absolutely

necessary and then only after careful obser-

vation of the entire area behind you.

If operator must dismount to make adjust-

ments the engine must not be running.

Do not move steering levers from forward to

reverse or reverse to forward position rap-

idly. The sudden change could cause loss of

control and/or damage to equipment.

Do not operate on steep slopes.

Do not stop, start or change directions sud-

denly on slopes.

The designed and tested safety of this

equipment depends on it being

operated within the limitations as

explained in this manual. Read

manual before operating.

TRAINING

Safety instructions are important! READ

THIS MANUAL AND ALL SAFETY

RULES.

Know your equipment’s controls and how to

stop tractor, engine and attachments quickly

in an emergency.

To avoid accident or injury, do not allow

anyone to operate this equipment without

proper instruction. Any person who operates

this equipment MUST be instructed in and

capable of the safe operation of the unit, its

attachments and all controls.

Do not allow children or unqualified indi-

viduals to operate equipment.

PREPARATION

Always wear relatively tight and belted

clothing to avoid entanglement in moving

parts. Wear sturdy, rough soled work shoes.

Never operate tractor or implements in bare

feet, sandals or sneakers.

Ensure attachments are properly mounted,

adjusted and in good operating condition.

Make sure driveline spring-activated lock-

ing collar slides freely and is seated firmly in

the tractor PTO groove.

Remove accumulated debris from attach-

ment and tractor to avoid fire hazard.

Ensure all safety shielding is in good condi-

tion and properly installed.

Ensure either the discharge opening restric-

tion plate, discharge shield or complete

vacuum attachment is installed.

Ensure all safety decals are installed and in

good condition.

Use correct counterweights when certain at-

tachments are installed (see specific