PREFACE

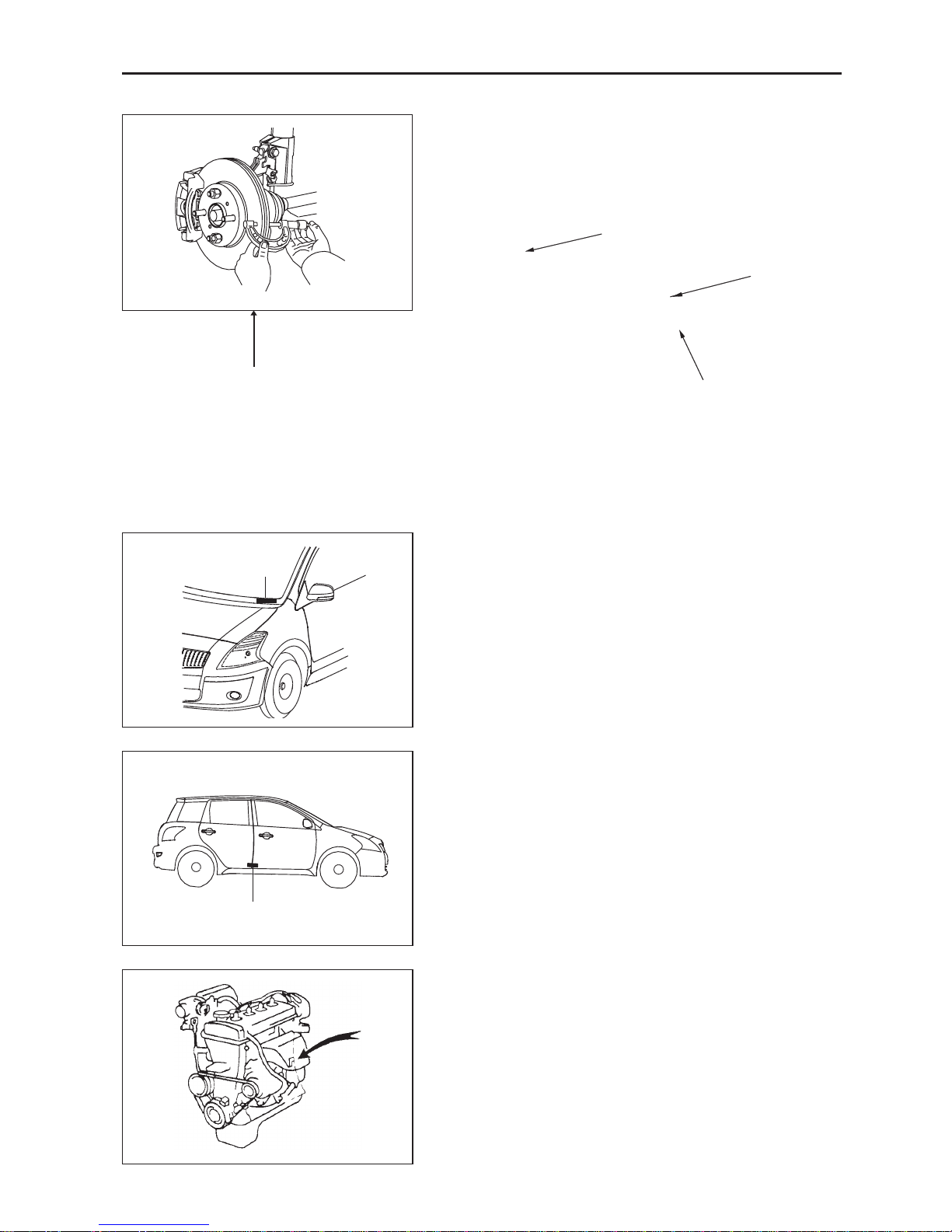

GWFLORID will build 1.3L (GW413EF, GW4G13) or 1.5L (GW4G15) gasoline engines, in which the

GW4G13 and GW4G15 engines will both incorporate the newest VVT technology which meets the Euro IV

emission standards. GWFLORID features McPherson technology on its chassis system. With an ultra light

body made from structural steel and high-intensity front and rear fender impact beams as well as a collision

impact absorption system, it is able to maintain the cab's integrity and safety to greater extent. We wrote this

maintenance manual in order to meet the demand of Great Wall after-sales service technicians. This manual

mainly introduces the areas of importance in regard to maintenance and care, and removal and installation of

each system's assembly and maintenance technical parameters.

To reduce the possibility of injury or property damage, read and follow the instructions carefully:

This manual is provided by the Great Wall Motor Co., Ltd, and is written for the technician use. Any

maintenance or repair without proper prior training and tools or devices may result in personal injury of the

person performing the maintenance or others in the vicinity. It is also possible that damage to the vehicle will

occur or will lead to mechanical failure during normal operation.

Correct vehicle maintenance and repair is essential for the safety of the person performing regular

maintenance as well as the vehicle itself. If there is any component that needs to be replaced, use a

component with the same serial number or a serial number specied by the Great Wall Motor Co., Ltd. Never

use any part that has not been authorized by the Great Wall Motor Co., Ltd.

Any maintenance procedure introduced in this manual is effective for maintenance and repair. Some of

these procedures need specially designed tools.

Therefore, before using any vehicle part following any maintenance procedure or working with a tool

that has not been authorized by the Great Wall Motor Co., Ltd, check to make sure that none of the above

will endanger the safety of the person performing the work or the correct operation of the vehicle.

This manual includes multiple "Warnings" and "Cautions," which should be strictly followed, so as to

reduce the possibility of injury during maintenance or repair. Improper maintenance or repair of the vehicle

may cause potential safety hazards. These "Warnings" and "Cautions" are not exhaustive. It is impossible for

the Great Wall Motor Co., Ltd, to warn against all the potential dangers caused by not properly following the

instructions.

Please read carefully the "Areas of Importance" before carrying out any maintenance or repair on the

airbag system's components or its surrounding electrical components. Action contrary to any of the "Areas of

Importance" may lead to the deployment of the airbag, resulting in injury or unnecessary repair of the airbag.

To avoid accidental deployment of the airbag and its resulting injury, we suggest repairing the airbag

system before other vehicle systems if the airbag and the other vehicle systems both need repairing.

We have received generous support and help from many professional technicians during the preparation

of this manual. We would like to express our heartfelt gratitude to all of them.

Although we have tried our best to write this manual well, we do not guarantee that the entire content

in this manual is absolutely correct. Users may not make any legal claim against the Great Wall Motor Co.,

Ltd. in regards to this manual. Any loss caused by using this manual is not our responsibility. Because of

the writer's limited experience, there are likely mistakes in this manual, therefore we welcome any user

comments, suggestions, and corrections.

Great Wall Motor Co., Ltd. reserves the nal right of explanation.

Editor

May 2008