page 3/47

CONTENT

page.

1. DESCRIPTION AND ADVANTAGES OF HOT AIR GENERATOR FROM SERIES

“PELLETHERM V.5/GENERATO”..............................................................................................4

2. TECHNICAL DATA FOR HOT AIR GENERATOR FROM SERIES

“PELLETHERM V.5/GENERATO”..............................................................................................6

3. CONSTRUCTION DESCRIPTION OF AUTOMATED HOT AIR GENERATOR

FROM SERIES “PELLETHERM V.5/GENERATO”..............................................................10

4. MOUNTING AND INSTALLATION................................................................................16

4.1. GENERAL CONDITIONS:...............................................................................................16

4.2. NORMS AND REGULATIONS.......................................................................................16

4.3. INSTALLATION OF THE GENERATOR......................................................................17

4.4. POSITIONING OF THE GENERATOR FOR EASY MANUPULATION..................17

4.5. CONNECTING THE GENERATOR TO A CHIMNEY.................................................18

4.6. СONNECTING THE GENERATOR TO AN AIR-FUNNEL FOR SUPPLYING THE

HEATING SYSTEM WITH HOT AIR .........................................................................................21

5. INITIALIZING THE APPLIANCE IN OPERATION......................................................23

5.1. GENERAL FUEL REQUIREMENTS .........................................................................23

5.2. INITIALIZIATION OF AUTOMATED PELLET HOT AIR GENERATOR FROM

SERIES “PELLETHERM V.5/GENERATO” IN OPERATION..............................................23

5.2.1. INTERFACE CONTROL PANEL OF AUTOMATED PELLET HOT AIR

GENERATOR FROM SERIES “PELLETHERM V.5/GENERATO”.....................................24

5.2.2. CONNECTION PANEL OF HOT AIR GENERATOR FROM SERIES

“PELLETHERM V.5/GENERATO”............................................................................................26

5.2.3. GENERATOR POWER SUPPLY.................................................................................26

5.2.4. GENERATOR SWITCH ON..........................................................................................27

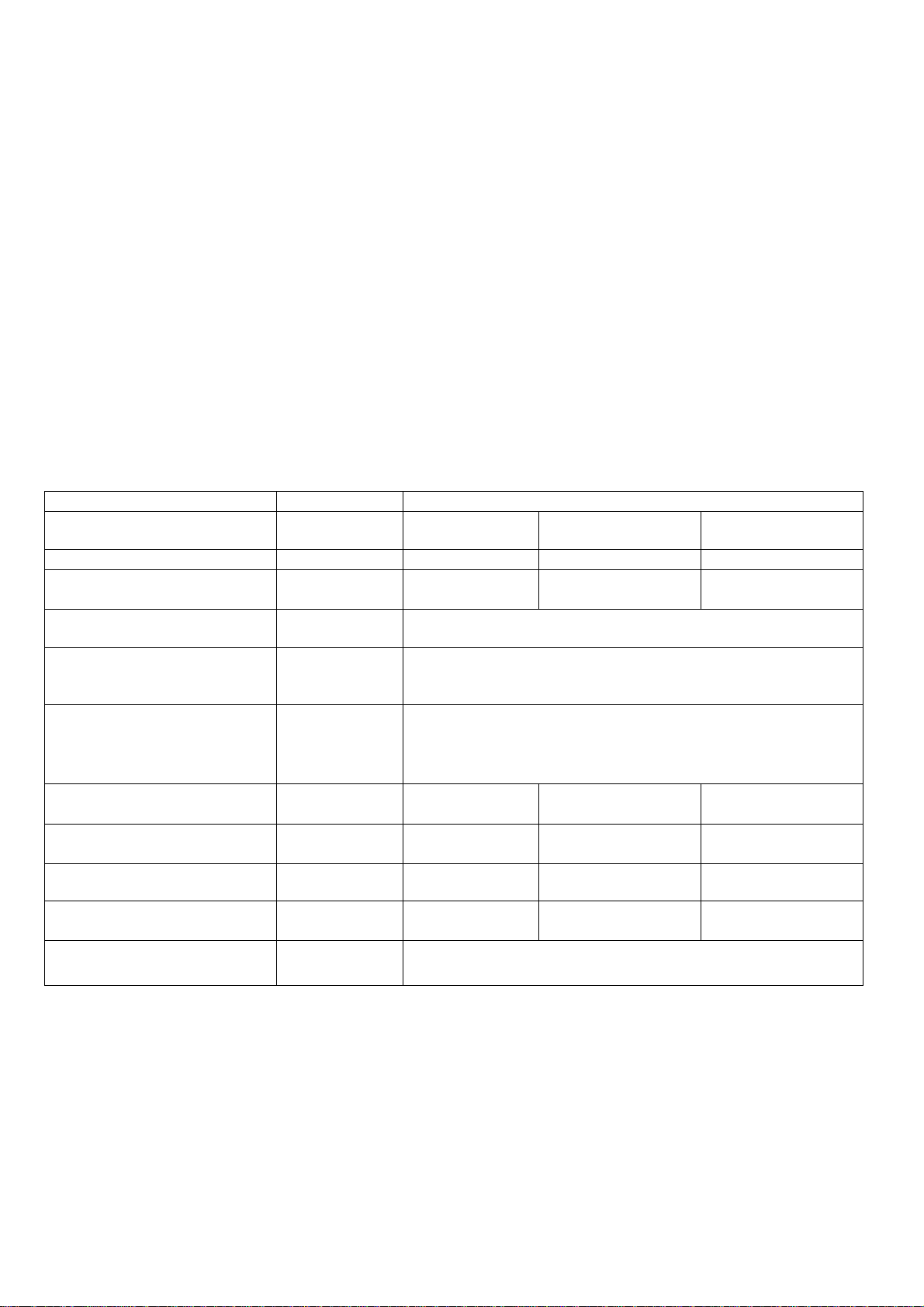

5.2.5. PARAMETERS FOR OPERATION ADJUSTMENT OF THE GENERATOR. .....28

5.2.6. ADJUSTING THE GENERATOR FROM SERIES “PELLETHERM

V.5/GENERATO” ACCORDING TO THE HEATING OUTPUT, CONSUMED BY THE

HEATED BUILDING/ CONSUMING APLLIANCES...............................................................31

5.2.7. CHANGING THE CONTROL MODULE OPERATION PARAMETERS. ..............34

5.2.8. NOMINAL OPEARATION MODE OF THE GENERATOR......................................36

5.3. REGULATING THE GENERATOR HEATING OUTPUT.......................................37

5.3.1. DECREASING THE GENERATOR HEATING OUTPUT. .......................................37

5.3.2. INCREASING THE GENERATOR HEATING OUTPUT..........................................37

5.3.3. ADJUSTMENT OF PARAMETERS FOR SUPPLYING THE HEATING AIR

FUNNEL SYSTEM........................................................................................................................38

5.4. STOPPING THE GENERATOR OPERATION. .......................................................38

5.5. GENERATOR SWITCH OFF......................................................................................38

5.6. INTRODUCING THE USER WITH THE APPLIANCE MAINTENANCE AND

ADJUSTMENT PROCEDURES.................................................................................................39

5.7. CLEANING THE GENERATOR.................................................................................39

5.8. SAFETY AND UNPREDICTED RISKS.....................................................................41

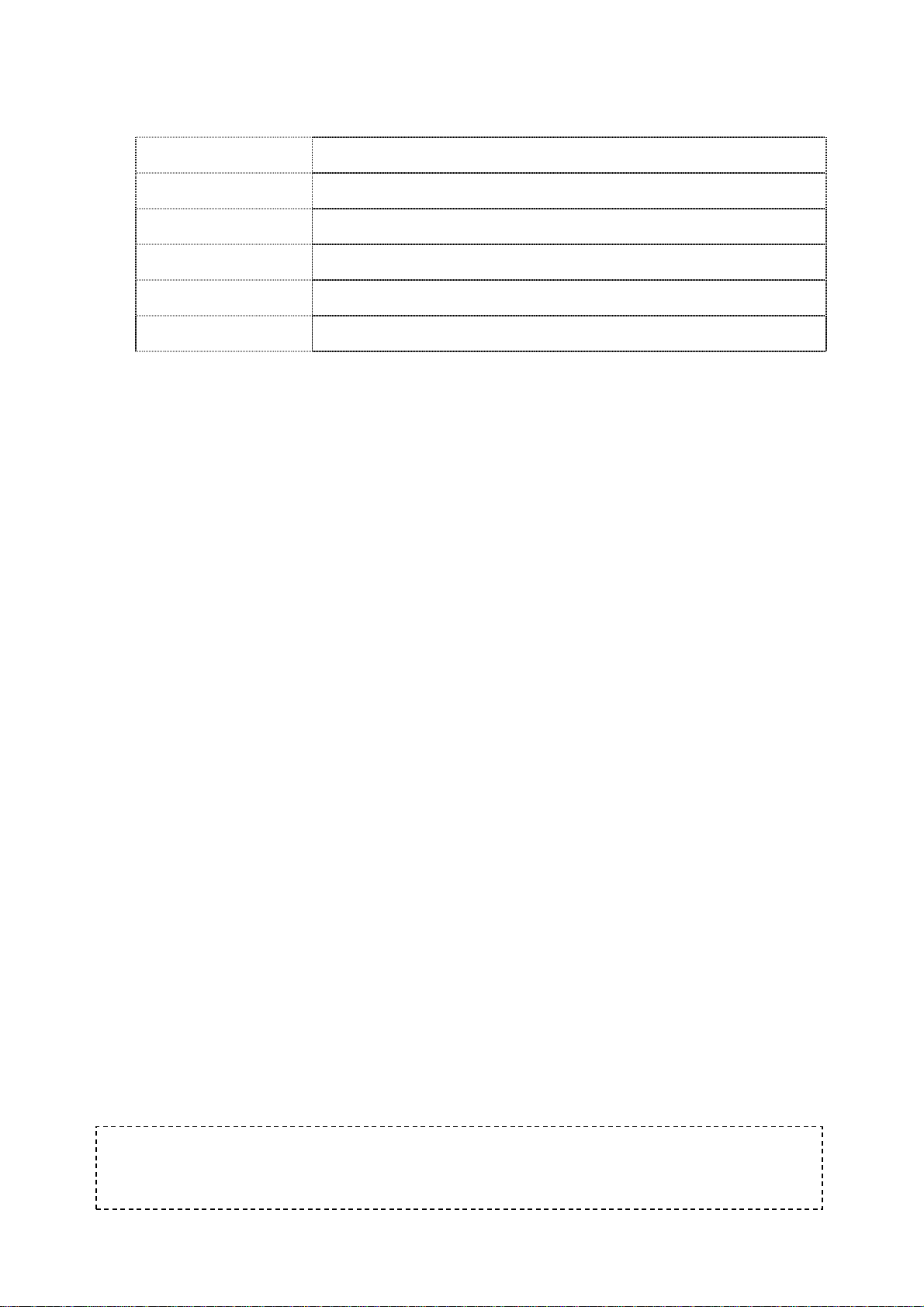

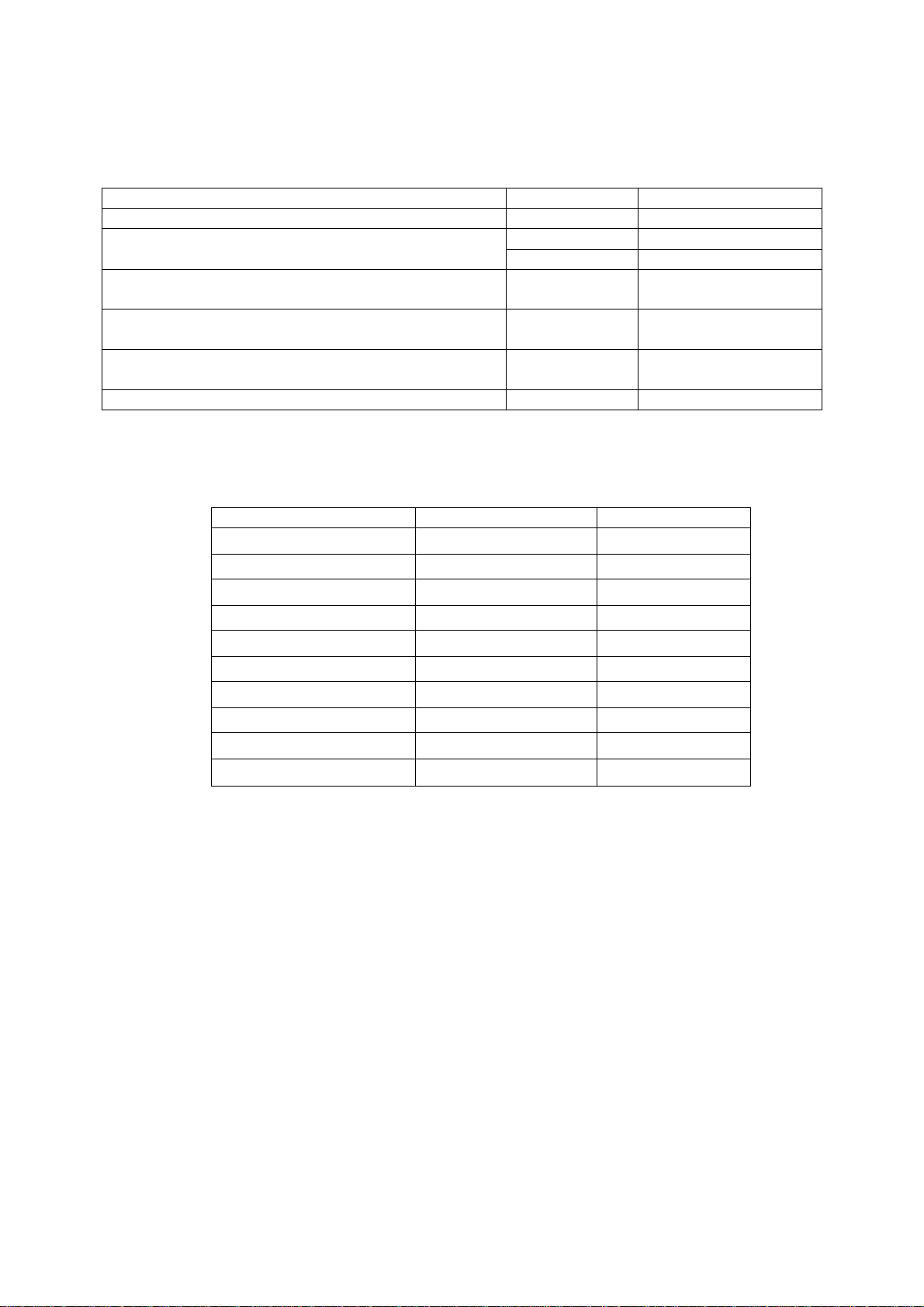

5.9. FAILURES AND TROUBLESHOOTING..................................................................42

5.10. COMPLETION OF THE APPLIANCE WARRANTY CARD....................................44

5.11. ACTIVITIES AFTER THE APPLIANCE LIFE CYCLE PERIOD EXPIRY. ..........44

6. WIRING DIAGRAM OF THE APPLIANCE...................................................................45