PBS SAFIR 5L User manual

PG 01-31

AUXILIARY POWER UNIT

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

ISSUED ON 4/2015

April 2015

2

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

AUXILIARY POWER UNIT

SAFIR 5L

OPERATION AND SERVICE MANUAL

PG 01-31

Issued on April 2015

This document is the property of

PBS Velká Bíteš, a.s.

and it is illegal to copy, use or promulgate it as a whole or in parts for any other purpose

without prior written consent of the Manufacturer.

3

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

LIST OF CHANGES AND CORRECTIONS

Change number Subject of change Validity Pages No. Performed by, date

L-KSS-3874

The parameters changing of the control box

based on the requirements from the

operation APU

From seriál

number APU

S5L 029

11, 59, 60

Bc. Tučková

17.2.2016

4

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

LIST OF CONTENTS

LIST OF CHANGES AND CORRECTIONS.................................................................................................................... 3

LIST OF CONTENTS........................................................................................................................................................ 4

LIST OF ILLUSTRATIONS.............................................................................................................................................. 5

INTRODUCTION .............................................................................................................................................................. 6

1.BASIC TECHNICAL DATA .................................................................................................................................... 7

Auxiliary Power Unit......................................................................................................................................... 7

Fuel System ....................................................................................................................................................... 8

Oil System ......................................................................................................................................................... 9

Air System ....................................................................................................................................................... 10

Control and Regulation System ....................................................................................................................... 11

Actuating System............................................................................................................................................. 12

2.OPERATION INSTRUCTIONS ............................................................................................................................. 21

Pre-Start Preparation........................................................................................................................................ 21

APU Actuation................................................................................................................................................. 21

Engine Actuation ............................................................................................................................................. 21

APU Cold Turn................................................................................................................................................ 21

APU Switch off................................................................................................................................................ 21

Monitoring and Signaling Equipment.............................................................................................................. 21

3.OPERATIVE LIMITS ............................................................................................................................................. 22

Actuation Repeatability ................................................................................................................................... 22

Low Temperature Operation............................................................................................................................ 22

Power Supplies ................................................................................................................................................ 22

Compressor Protection..................................................................................................................................... 22

Control System Protection ............................................................................................................................... 22

Air Intake Limits (in 100 % Mode) ................................................................................................................ 22

Permissible Overload with APU Switched off ............................................................................................... 23

Fluids in Use.................................................................................................................................................... 23

APU Actuation in flight................................................................................................................................... 24

Other Limits..................................................................................................................................................... 24

4.SERVICE INSTRUCTIONS ................................................................................................................................... 25

General Survey ................................................................................................................................................ 25

Assembly and Operation Instructions.............................................................................................................. 25

Instructions for Replacement of APU In-Operation ........................................................................................ 27

Activation ........................................................................................................................................................ 27

Definitions of Periodic Work........................................................................................................................... 28

Time-limits of Activity – Technical Resource................................................................................................. 30

Scope of Periodic Work................................................................................................................................... 30

Checking Techniques....................................................................................................................................... 33

5.DEWAXING AND PRESERVATION IN OPERATION .................................................................................... 51

Dewaxing – on Delivery from the Manufacturer (replacement parts, after repair, etc.) .................................. 51

Dewaxing after 3 Months Preservation, Performed In-Operation. .................................................................. 51

First Actuation of APU.................................................................................................................................... 51

Preservation Valid for 30 Days........................................................................................................................ 51

Internal Preservation Valid for 3 Months +18-9 Days ........................................................................................ 51

Preservation Valid for 1 Year .......................................................................................................................... 52

Preservation and Packing for Shipping Devices to the Manufacturer............................................................. 52

6.DEFECTS AND TROUBLESHOOTING.............................................................................................................. 53

General Survey ................................................................................................................................................ 53

Explanatory Notes to the Schematic Diagrams................................................................................................ 54

List of Algorithms for APU Function Monitoring and Troubleshooting......................................................... 55

5

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

APPENDIX:

Pages

APPENDIX No.1 Technical and operating manual of Control Box LUN 3594.04 34

APPENDIX No.2 Dimensional Drawings 9

Auxiliary Power Unit SAFIR 5L P/N 490100.02

Block of Filter and Servo P/N 490740.01

Fuel Pump P/N 490720.01

Return Fuel Filter LUN 7616-8

Oil Tank P/N 490620.03

Oil Pump LUN 6320-8

Anti-surge valve P/N 490330.03

Ignition exciter P/N 81550.01

Control box LUN 3594.04

APPENDIX No.3 Auxiliary Power Unit SAFIR 5L – Interface Control Document (ICD) 2

LIST OF ILLUSTRATIONS

Fig.

No. Page

1. Fuel System Diagram 13

2. Oil System Diagram 14

3. Air System Diagram 15

4. Wiring Diagram with control box LUN 3594.04 16

5. APU Function Flow Chart 17

6. Timing Behavior of APU Start and Operation 18

7. Time Behavior of APU Protective Circuits 19

8. Kinematic Diagram of APU Gear Box 20

9. Oil Pump LUN 6320-8 41

10. Broken-out Section of APU Air Generator 42

11. Permissible Defects of the Combustion Chamber 43

12. Sectional View of the Block of Filter and Servo 490740.01 44

13. Sectional View of the Return Fuel Filter LUN 7616-8 45

14. Broken-out Section of the Oil Filter 490131.01 46

15. Oil Tank 490620.03 47

16. Ignition Plug 85500.11 instalation 48

17. Interconnecting conductor 490510.01 48

18. Speed Transmitter LUN 1326.03-8 49

19. Electric-Starter 490110.01 50

6

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

INTRODUCTION

This Manual is intended for technicians and mechanics, who support the operation of the Auxiliary Power Unit SAFIR

5L.

It contains instructions for all work that will occur during the APU operation in the time till the complete overhaul.

The adherence to these instructions is the prerequisite of achieving a reliable operation and endurance of APU. The

minute command of these instructions is, therefore, in the interest of the operating organization.

The non-observance of these instructions during operation or troubleshooting, which is not allowed by these

instructions, divest the user of warranty and the Manufacturer is not liable for possible damages arising thereof.

7

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

1. BASIC TECHNICAL DATA

Auxiliary Power Unit

Identification, type: SAFIR 5L

Description: Turbo-reactive engine with automatic control and air

outtake from compressor

Compressor: single stage, radial

Technical parameters for standard conditions: See article 1.4

Combustion chamber:

Turbine:

Operating speed (100%):

Idling speed (89%):

APU weight without exhaust pipe

Weight with accessories

annular

two- stage, axial flow

51 900 rpm

46 400 rpm

31 kg

42 kg

Fuel: T1,T2,ТS-1

according to:

GOST 10227-86

JET A, JET A-1, JET B

according to:

- DERD 2494 (Brit. Specification)

- MIL-T-83133D (US Specification)

JET A-1

according to:

- DEF STAN 91-91

- AFQRJOS

- STAS 3754-77

JP 8,

according to:

- DERD 2453 (British Specification)

- MIL-T-83133D (US Specification)

RP-1,

according to:

(GB 6537-86)

RP-2,

according to:

(GB1788-79

)

RP-3,

according to:

(GB 6537-86)

Cleanness the fuel must conform to the class 10-11 according to GOST 17216-71 or 7 - according to NAS 1638

Oil: AEROSHELL TURBINE OIL 500 a 560,

according to:

MIL-L-23699D

MOBIL JET OIL II,

according to:

MIL-L-23699D

IPM10,

according to:

ОSТ38.01294-83

MS – 8P,

according to:

ОSТ38-01163-78

B3-V ,

according to:

TU38-101-295-85

HP-8B,

according to:

GB 439-1990

Cleanness the oil must conform to the class 14 according to GOST 17216-71 or 10 - according to NAS 1638

Warning: The using of other fuels and oils with the APU manufacturer permission only!

Power supply: Accumulator 24 V, 25 Аh

(charged at least to 75 % of its nominal capacity)

Number of actuations per 1 charge of the accumulator: at least 4

Operation voltage range: 23,5 – 28,5 V

Height for start of APU and engine and

air intake for the airplane air conditioning: 26 500 ft (8 000 m)

Ambient temperature range for reliable function of

APU:

-60 °С+60 С(-76 F +140 F), (with the restrictions

under article 3.2)

Time of APU operation in maximum mode (100%): 120 min. max.

Repeatability of APU actuation and engine see article 3.1

Fuel consumption: 70 kg/hour max.

Oil consumption: 150 cm3/ hour max.

8

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

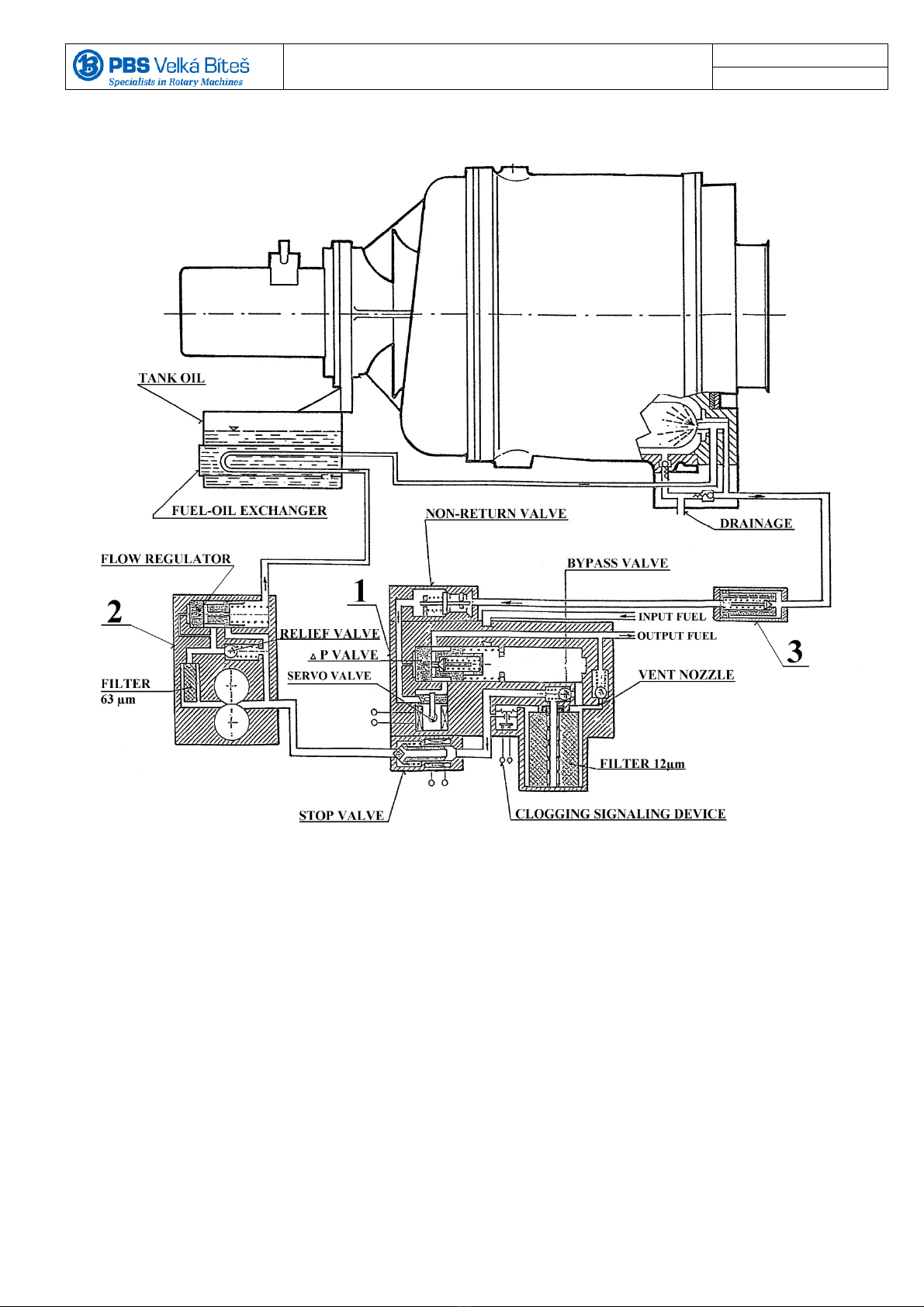

Fuel System

Description:

flow rate:

Max. pressure

low-pressure, with constant input flow rate, with twelve

bypass nozzles and throttled output

130±5 l.hour-1

1,3±0,1 MPа

Working fuel temperature -40 ÷ +60 °C

Block of Filter and Servo: 490740.01

-filter efficiency 12

m

-signaling of clogging switches on, when pressure loss in the filter element

reaches 359 kPа

-filter relief valve turns on, when pressure loss in the filter element reaches

5512 kPа

-electromagnetic valve opened when energized, max. current consumption 1,5 А

-servo-operated valve current consumption 0-150 mА

modulation 250 Hz – 500 mV

-non-return valve opens when pressure exceeds 10 kPа

-thermoregulator 32 С(89.618 F)

-air-relief valve opens at pressure amounting to 20 kPа

-slide-valve adjustment at 10010 kPа

Fuel pump: 490720.01

-type single stage, gear-type

-filter 63

m

-delivered quantity 130±5 l.hour-1 (depended on operation mode)

-pressure 1,3±0,1 MPа

Fuel - oil exchanger: Tubular

Fuel nozzle: bypass (with fuel bypassing)

-number of nozzles: 12

Fuel ramp drainage valve: DV-1

-closes at fuel pressure amounting to: 15+10 kPа

Combustion chamber drainage valve: DV-2

-closes at air pressure amounting to: 36+2-8 kPа

Return fuel filter: LUN 7616-8

-filter efficiency 12

m

-bypass set to 305 kPа

9

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

Oil System

Description: autonomous, directly deaeration with open circulation

-flow rate 45 l.hour-1

-oil pressure 210 kPаmax.

-minimum oil pressure

-operating oil temperature

885 kPа

-40 ÷ +140 °C (-40÷284 F)

Oil tank: 490620.03

-total volume 2 l

-"MAX." level mark volume 1,3 l

-”MIN” level mark volume 0,8 l

-level indicator Glass pipe

-relief valve opens at pressure amounting to 40+5-10 kPа

-drain plug with magnet

-filler neck with quick-closing valve and screen

filter efficiency 200

m

-fuel - oil exchanger tubular

-output filter, filter efficiency 80

m

Oil pump: LUN 6320-8

-description single stage

-drive from APU gear

-change-over ratio 1:7

Oil filter: 490131.01

-filter efficiency 35

m

-differential pressure indicator

LUN 1491.22

switches on, when the filter element losses reach 405kPa

-cleaner relief valve opens, when pressure losses in the filter element reach

555 kPа

-pressure switch of oil filter

LUN 6751-8

switches on, when pressure decreases to 805 kPа

-electromagnetic valve opens when energized, current consumption

with voltage 27 +1 VDC < 1,5 А

Electromagnetic valve: 486611.01

-function opens when under voltage (alive)

-current consumption < 350 mА

Electromagnetic fuel valve: LUN 2475-8

-function opens when under voltage (alive)

-current consumption < 1,5А.

10

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

Air System

Carakteristic

Air parameters behind anti-stall bleed valve at 100 %

speed mode (for ISA, H=0m)

Output

-air flow ≥1920 kg.h-1

-air presure ≥348 kPa

-warming of the air in the compressor

-air inlet temperature

190 С(374 F)

-60 ÷ +60 С(-75.982 °F ÷ +140,018 °F)

Venturi tube:

-purpose

33 mm

APU protection

(part of the anti-stall bleed valve, restricting the air

quantity from the compressor and protect turbine

overheating)

Anti-surge valve 490330.03

-closing initiation at the Venturi tube over-pressure

of

55±5 kPа

-opening initiation at the Venturi tube over-pressure

of

70±5 kPа

visor in the output throat of the anti-stall bleed valve

27 mm

11

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

Control and Regulation System

Description: electronic

Speed transmitter: LUN 1326.03-8

-purpose produces the input signal for electronic control

-type electromagnetic

-output voltage 1 V on 2145 Hz 5 %

-location on the APU gearbox

-tooth-wheel with circumferential holes number of holes: 36

-conversion ratio rpm / Hz 11,668

Temperature Transmitter

-purpose

-type

-number off transmitter

LUN 1371.01-8

produces the input signal for electronic control

Thermocouple CHROMEL-ALUMEL

3

Control box: LUN 3594.04

-purpose - controls the APU speed according to the mode selected

- controls the function of electric accessories

- type

- performs the APU closing

- digital

-preset modes - full operating speed 100 % 51 900 rpm

- idling speed 89 % 46 400 rpm

-APU protections (levels of setup) - maximum speed 109 % 56 660 rpm

- sub-speed 79 % 41 200 rpm

- closing during actuation, when the

exhaust gas temperature does not reach

150 С(302 F) within

13 sec.

- closing of APU during actuation, when

sub-speed (70 %) is not reached within

35 sec.

- high temperature of the exhaust gases is

signalized, when the temperature reaches

850± 15 С

(1562±59 F)

- In case of exceeding the set exhaust gases

temperature - the control box will perform

decrease of turbine speed until reaching of

the set temperature of the exhaust gases.

800 ± 15 °C

(1472±59 F)

Signaling on the control panel in the pilot’s

compartment which will not cause closing of APU:

- rotation speed 89 %

- rotation speed 100 %

-high gas temperature

-clogging of the oil filter

-clogging of the fuel filter

Detailed description of technical characteristic and operating work of the Control Box LUN 3594.04 see Enclosure

No. 1) – document PRP-2011-602-02-801, Technical and operating manual.

12

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

Actuating System

Ignition exciter P/N 81550.01

type high-energy

nominal voltage 28 V

output voltage 2,5-3 kV

number of outputs (for ignition plug) 1

Type of ignition plug

The interconnecting conductor (length1100mm)

85500.11

490510.01

Electric-starter

type 490110.01

output on 4600 rpm 1,25 kW

maximum terminal voltage 26 V (see article 3.10)

maximum speed 28 800 rpm

change-over ratio 1:1,96

clutch overrunning, centrifugal, torque - slip

slip moment 10+0,5 Nm

13

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

1 – BLOCK OF FILTER AND SERVO 490740.01

2 – ELECTRIC FUEL PUMP 490720.01

3 – RETURN FUEL FILTER LUN 7616-8

Fig.1. Fuel System Diagram

14

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

1 – OIL TANK 490620.03

2 – OIL PUMP LUN 6320-8

3 – OIL FILTER 490131.01

4 – ELECTROMAGNETIC VALVE 486611.01

5 – ELECTROMAGNETIC FUEL VALVE LUN 2475-8

Fig.2. Oil System Diagram

FILTER

80 μm

15

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

1 – ANTI-SURGE VALVE 490330.03

Fig.3. Air System Diagram

ø33

Bleed nozzle

ø27

16

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

Fig.4 Wiring Diagram with Control Box LUN 3594.04

17

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

Fig. 5. APU Function Flow Chart

APU - Auxiliary Power Unit SAFIR 5L

FP - Fuel Pump

EV1 - Electromagnetic Fuel Valve of Filter and Servo Block

EV2 - Electromagnetic Valve of Oil Filter

EV3 - Electromagnetic Valve of Oil Tank - air vent.

EV4 - Electromagnetic Valve of Oil Drain

ES - Electric Starter

EU - Ignition Exciter

ATS - Pneumatic Starter

TP - Speed Transmitter

EC -Control Box

EV1, EV2, EV3, EV4 - open

FP, ES, EU - when nergized

Timing circuit

2 – 10 – 13 – 35 s - actuated

APU Start up

After 2s Control Systém

does not have adequate

signal from TP

Sub-speed reached in 35s ES, EU

disconected from thepower supply

Timing 13 s

reached at the exhaust

gases

temperature˂150°C

(

302°F

)

Timing 35

s finished before

reaching

sub-s

p

eed

The APU speed reached

idlin

g

APU CUT – OFF

by pilot

Inadequate oil pressure

after 30s

of APU operation

By switching

off the svitch

„DELAY

STOP“

Decrease the rotational

speed at idle and two

minutes waiting at idle

in order to cool the

turbine.

EV1, EV2, FP - disconnected from power supply

Timing 180s - actuated

After 180s EV3, EV4 switched off

from the power supply

By switching off the svitch

„EMERGENCI STOP“

The APU reached

The operating speed

APU CUT – OFF

by automatic protection system

Two brakers and

switch switched

RUN

Push the

START BUTON

18

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

rpm

% min-1

110

100

90

80

70

60

50

40

30

20

10

0

56650

51900

46400

41200

0 5 10 15 20 25 30 35 40 45 50 100 200 300 400 500 600

Times

1. Initiation of the start APU after switching on of the power supply circuit by switching on the relevant breakers and

switches "RUN" and push down the "START BUTON"

2. Ignition of fuel in the combustion chamber

3. Start of electronic control function

4. Attainment of sub-speed (80 %)

5. Attainment of idling (89 %)

6. Reaching operating speed (100 %), cold and hot start of the main engines

7. APU cut-off by pilot, after finishing the main engine starting, by switching off the switch „DELAY STOP“

Reaching idle (89 %), and two minutes waiting at idle in order to cool the turbine

8. Automatic shutdown of the APU running.

9. Stop the APU rotor

Minimum total running time APU which is necessary for the successful launch of the two main engines is five minutes.

Immediate interruption of the function APU is possible to switching off the switch "EMERGENCY STOP"

APU start, operation and switch off

permissible range of the speed APU

Fig. 6. Timing Behavior of APU Start and Operation

2

3

4

5

6 7

8 9

10

1

19

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

1. APU switch off resulting from inadequate signal level of the speed transmitter

or from a speed transmitter circuit failure

2. APU switch off resulting from failure to achieve exhaust gas temperature of 150 oC (302 oF)

(no ignition of the combustion chamber) within 13 s after the start

3. APU switch off resulting from failure to achieve APU sub-speed within 35 s

4. APU switch off after 35 s resulting from low oil pressure

5. APU switch off resulting from reaching over-speed

6. APU switch off resulting from decrease of APU speed bellow the lowest permissible value

7. Decrease of oil pressure during APU operation after 35 s timing

8. End of pressure switch bridging (14 s) and interruption of the APU function resulting from low oil pressure

APU start, operation and switch off in the Idling Mode

APU start, operation and switch off in the 100 % Speed Mode

permissible range of speed

Fig. 7. Timing Behavior of APU Protective Circuits

20

SAFIR 5L

OPERATION AND ATTENDANCE MANUAL

PG 01-31

1. Electrоstarter Conversion ratio 1:1,96

2. Oil Pump Conversion ratio 1:7

Fig. 8. Kinematic Diagram of APU Gear Box

Table of contents

Popular Portable Generator manuals by other brands

Champion

Champion 42436 Owner's manual & operating instructions

Generac Power Systems

Generac Power Systems Mobile Power MMG185 Specifications

IPC

IPC SG-70 instruction manual

Olympus

Olympus OME-L200 instructions

Koshin America Corporation

Koshin America Corporation GEH-7200EX Insert

Global

Global 8550-SD operating manual