Green Panther GP-4019BP-P User manual

Note: Please read the following instructions before use. This book contains important information on SAFETY, ASSEMBLY, OPERATION

& DISCLAIMER: DUE TO CONSTANT UPGRADATION, FEATURES AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

GP-4019BP-P

BRUSH CUTTER BACK PACK

USER MANUAL

2

GENERAL INSTRUCTIONS FOR SAFETY OPERATION

All our company products are delivered with an Owner’s manual. Please read it carefully to get

acquainted with the operation of your unit. For further details, consult your dealer.

Before Operation

Protect head (eyes and ears), feet and hands with safety hat, ear cover, goggles, safety shoes

and protective clothes.

Dress properly, do not wear loose clothing or jewelry that could become caught in moving parts

of the unit.

Never let a child operate the machine.

Be sure to check bolts and other fasteners to see if any of them have become loose or missing.

Cutting blade

- The cutter blade is very sharp, handle it with care.

- To install the blade correctly, read the instructions in this manual thoroughly.

- The Cutter fixing blot is left threaded, turn counter-clockwise to tighten, clockwise to loosen.

Fuel

NEVER OPERATE THE ENGINE WITH GASOLINE ONLY.

The engine requires a fuel mix of 25 parts regular gasoline to I part quality two- cycle oil

Do not fill the fuel tank while the engine is running or still warm. The fuel should be poured into

the fuel tank when the engine is cold.

Do NOT SMOKE WHEN FUEL IS ADDED, and when you are working with the machine.

Keep an open flame away becaruse fuel vapors are flammable.

Never smoke or allow a flame to come close to the unit while mixing fuel, filling the tank or

maintaining the unit.

Fuel should be stored in a dry and cool place.

During Operation

The unit should be operated in a well wentilated area.

Keep children away.Onlookers should be kept at a safe distance from the work area, at least 7 -

8m(30 feet).

Keep all parts of your body and clothing away from the blade when starting or running the

engine.

While cutting, hold the machine firmly with both hands, and stand with feet well-balanced and

your body balanced.

3

GENERAL INSTRUCTIONS FOR SAFETY OPERATION

The operator must obey the local regulations of cutting area.

Never carry the unit with the engine running.

For safety, the unit should not run in full throttle without any load.

Don’t run the unit without a muffier.

During a heavy work, be always with a partner.

When making a repair or adjustment, the unit must be stopped and the fuel completely drained.

For Long-term Storange

Drain all fuel from the carburetor, fuel tank and fuel lines.

Repair any damage which has resulted from use.

Clean the unit with a clean rag, or the use of high pressure air hose.

Put a few drops of engine oil into the cylinder through the spark plug hole, and spin the engine

over several times to distribute oil, then reinstall the spark plug.

Cover the unit and store it in a dry area.

Brush Cutter is composed of three major units;engine, flexible shaft and drive shaft.

1. Assembling drive shaft (Fig. I)

Insert the flexible shaft into the joint pipe of Drive Shaft to the end and tighten the joint pipe bolt

by engaging the bolt to the slot of flexible shaft.

NOTE:Make sure to align square end of flexible inner shaft with square hole of drive shaft by

slightly rotating drie shaft. So that they arc connected firmly.

2. Assembling flexible shaft (Fig.2)

Remove temporarily installed PIN. Insert flexible shaft into clutch case to the end by inserting

square end of flexible inner shaft into square hole of adaptor m Clutch Case. Then screw-in the

PIN by engaging the pin the slot of flexible shaft.

4

3.Throttle cable and stop cord

Put throttle cable and stop cord through cable passage of shaft grip,then connect each terminal

with each proper position respcctively.(Fig.3)

Finally,clamp those connected throttle cable and stop cord together to flexblc shaft with two wire

clamp bands provided.(Fig.4)

4. Haldle (Fig.5)

Remove the handle bracket A.

Set the handle on, and attach the handle bracket A with two bolts slightly. And adjust position of

the handle according to your working style. Then fix it firmly with the bolts.

5. Safety cover(Fig.6)

1) Install the safety cover on the shaft with the safety cover bracket and the screws proivded.

2) Tighten the rcrews after setting the safety cover bracket at the appropriate position.

5

6. Blade

I) When installing a steel blade, fit the blade as shown in the fig. 7

2) When installing or removing a blade, lock cutter holder with lock handle to tighten or to

untighten

as shown in Fig. 8

NOTE: As the blade fixing bolt is left threaded, tum it counter-clockwise and take a special care

not to hurt your fingers by the blade. Be sure to check if it has been fitted correctly.

Adjust shoulder belt length as you feel appropriate before starting engine.

I. Filling the fuel (Fig.9)

1) This engine uses a fuel mix of 25 parts regular gasoline to I part of two-cycle oil. The fuel

should be premixed prior to pouring into the fuel tank. It is recommended a quality twocycle oil

be used in the fuel mix.

CAUTION:FAILURE TO MIX OIL WITH GASOLINE WILL RESULT IN SEIZURE

AND SEVERE DAMAGE TO THE ENGTNE.

2) Be sure to check bolts and other fasteners to see if any of them have become loose or missing.

OPERATING PROCEDURES

6

2. Starting

I) Open the fuel cock. (Fig. I 0)

2) Move the throttle lever to start position or about I /4 full throttle, in case of metal lever.

(Fig. II)

NOTE: Staring with full throttle causes sudden high revolution of Blade, which is dangerous,

so please avoid it.

3) Set the choKe lever to CLOSE. (Fig. 12)

4) Pull the recoil starter briskly, TAKING CARE TO KEEP THE HANDLE in your grasp, while not

allowing it to snap back.

5) When you hear con:bustible sounds a couple of times, move the choke lever back to as it is

(open position). Then pull the recoil starter briskly.

6) After starting the engine,allow it about 2-3 minutes to warm up before subjecting it to any load.

CAUTION : Biade may turn and flexible shaft may swing as engine starts. Do not let the

blade touch any object when engine starts.

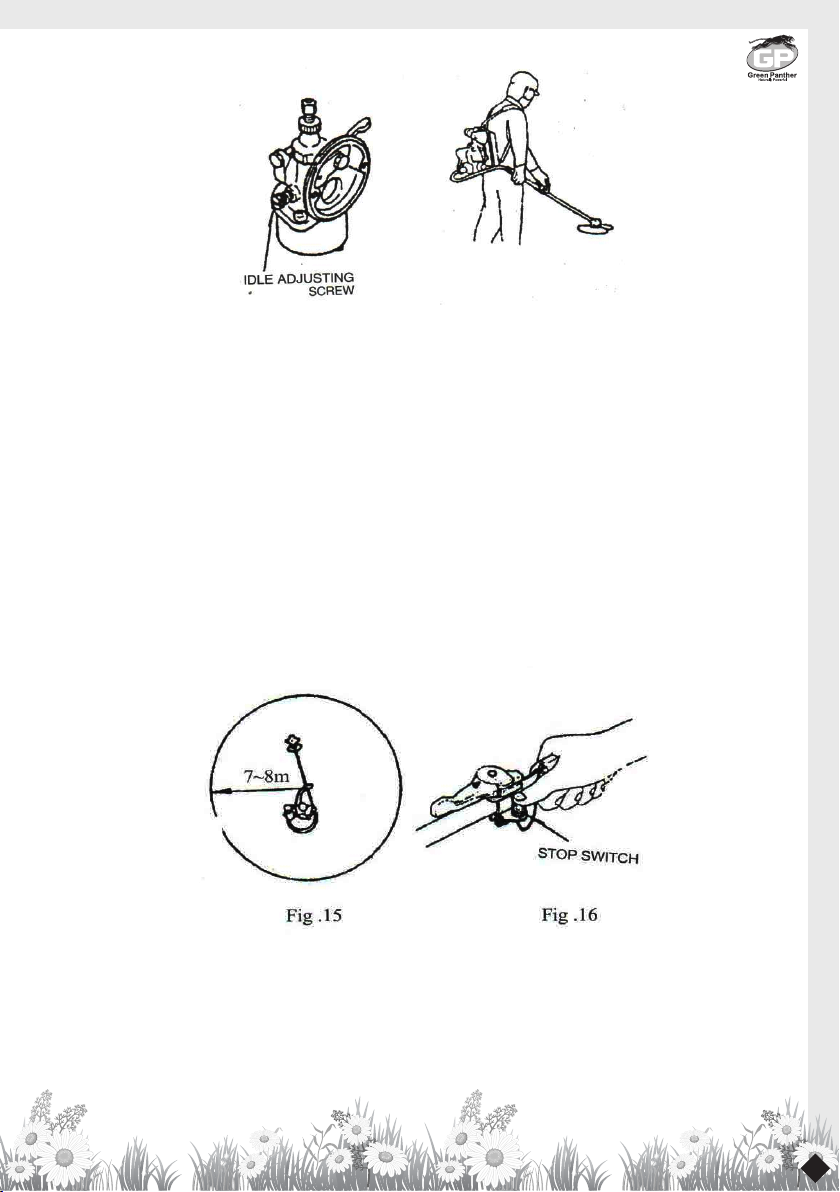

* Adjustment (Fig. 13)

When the idle speed is too high or too low,adjust it with the idle speed adjusting screw.

In case that the blade keeps turning at the idling speed, turn the idle adjusting screw

counterclockwise.

3. Ilow to carry (Fig.l4)

I) First, hold the handle with your left hand and bend yourself down. Slip your right arm into the

right belt.

2) Transfer the shaft to your right hand and reaching back,slip the left arm through the other belt.

3) When the engine unit is mounted on your back, grip the shaft as shown in the figure.

7

4. Cutting

I) The blade turns counterclockwise, therefore be advised to operate the cutter from right to

leftward for efficient cutting.

2) When working on a slope,the blade should allow the contour from top to bottom, with the

operator looking down to the left.

3) Keep the onlookers out of the working area at least 7~8m (30ft). (Fig. IS)

4) Special care

If the cutter should strike against stones or the like, stop the engine and cutter and make sure that

the cutter and related parts are in normal condition.

When grass or vine twines round the cutter, stop the engine and blade and remove grass or vine.

5. Stopping

1) Decrease the engine speed, and depress the stop button until engine has stopped. (Fig. 16)

8

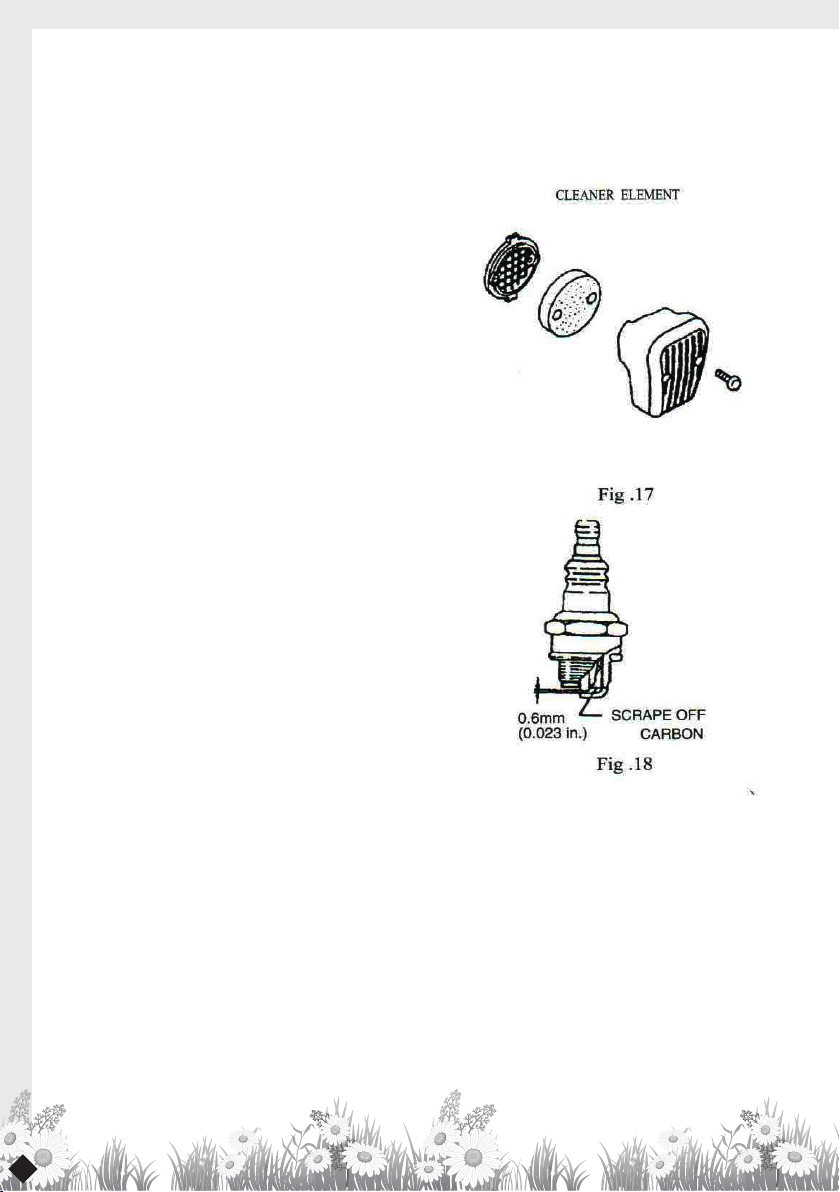

3. I. Periodical check

l) Cleaning

l - l Clean the cleaner element. (Fig. 17) I - 2 Scrape

off the carbon from the spark plug gap (standard

gap is 0.6mm or 0. 023in. ). (Fig. 18) 1 - 3 Clean the

cylinder exhaust port and muffler.

Remove the grasses or dusts entered in the

cylinder cover or fan case cover (otherhwise they

may cause a trouble such as an overheating).

2) Inspect carefully for any fuel or oil leaks.

3) Check all nuts, bolts, screws, etc., making sure

they are tightened and secured as they should be.

4) Lubricate Gear Case, every 50 hours of use.

5) When lubrichting flexible shaft, apply grease

in the flexible pipe of clutch case side. (It is

recommended to apply grease after every 10 hous

of use.)

2.Storage

I) Completely drain the fuel out of the tand and the

carburetor.

2) Keep the engine always to be highter than gear

box part.

3) Clean the unit carefully and keep it from

moisture.

Before installation,putthrottle,cable and stop cord

through cable passage of the shaft grip.

I) The throttle lever and stop switch are temperially assembled together. so they should be

disassembled first.

2) Put the round head of throttle cable and throttle cable together into the handle channel.

3) Fix the throttle lever on the hard shaft.

4) Finally,fix the stop switch on the throttle lever with a screw.

MAINTENANCE

9

SPECIFICATIONS

Model 4019BP-P

Engine Type Brush cutter

Dispiacement 42.7cc

Max.Output 1.25kw 6500rmin

Carbureor Diaphragm type

Lgnitiop system rc [gnition

Lgnition plug BM-A

Fuel Mixed fuel of Gasoline and 2 cycle oil at 25: I

Fuel tank capacity 1.2L

Body Drive Flexible shaft, Drive shaft,Pinion and Gear

Rotational direction

of the cutter

(Viewed from the

top of the cutter)

Counter-clockwise

Dry weight I 0.7kg

10

PARTS LIST FOR OUR COMPANY BACK-PACK BRUSH CUTTER MODEL

FOREWORD

l.The parts list contains listing for all the spare parts available for the OUR COMPA”--Y BACK.

PACK BRUSH CUTTER MODEL and should always be used \\.hen ordering

genuine OUR COMPANY parts.

2. You may happen to receive ordered parts with a slightly different parts number which has

nothing to do with interchangeability, but it is improved one.

3. In this parts list there may be some different accessories or optional parts from your unit for

this manual covers several models.

HOW TO READ PARTS LIST

I. When “V” appears in the quantity column, the quantity of the specific part is variable and will

have to be determined when the unit is reassembled.

2. The following abbreviations are used in

this list:

COMP. (COMPLETE) ... This represents

a part made of two or more pieces

permanently fastened together, which

cannot be broken down into separate

parts.

ASS’Y(ASSEMBLY) ... This represents a

part made of two or more pieces which

can be broken down into separate parts.

HEX. . ........ HEXAGONAL

SCREW ...... ROUND HEAD SCREW

F. H.SCREW ........ COUNTER SU”JK

SCREW

WASHER ...... FLAT WASHER

S.WASHER ...... SPRING(LOCK)WASHER

S.NUT ...... SPECIAL NUT

Table of contents

Other Green Panther Brush Cutter manuals