HG3555A/42306 Portable Power Unit

Greenlee Textron / Subsidiary of Textron Inc. 24455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

Table Of Contents

OPERATION

Safety Information ...........................................................................................................................................3-4

Description .........................................................................................................................................................4

Identification .......................................................................................................................................................5

Specifications – HG3555A/42306 Portable Power Unit ..................................................................................... 6

Specifications – Gasoline Engine.......................................................................................................................6

Recommended Hydraulic Fluids ........................................................................................................................6

Hoses and Fittings ............................................................................................................................................. 6

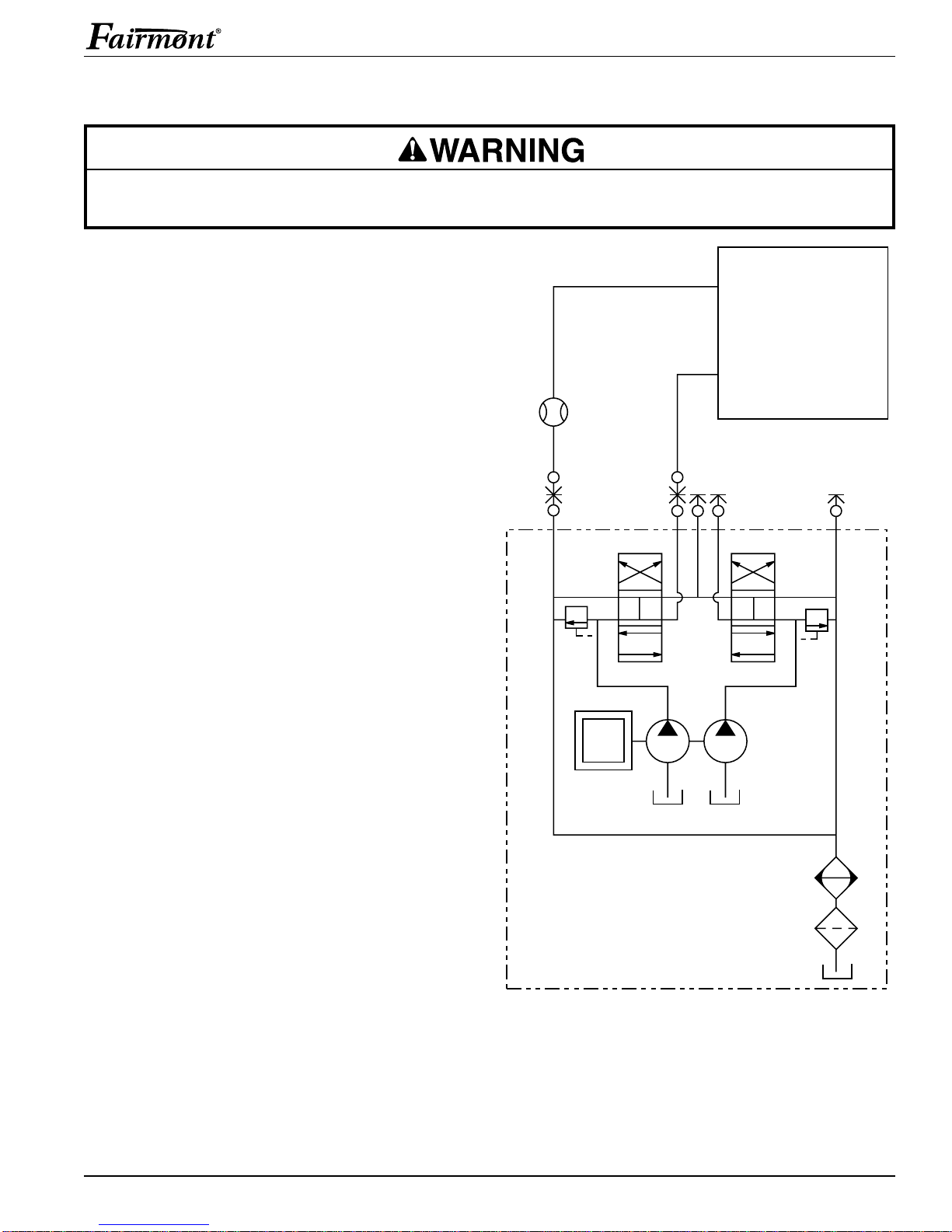

Hose Connections.............................................................................................................................................. 7

Operation ......................................................................................................................................................8-10

MAINTENANCE

Depressurizing Hydraulic System .................................................................................................................... 10

Maintenance Schedule.....................................................................................................................................12

Battery.............................................................................................................................................................. 13

Pneumatic Tires ...............................................................................................................................................13

Troubleshooting ..........................................................................................................................................13-15

PARTSPower Unit...................................................................................................................................................16-17

Hydraulic Components and Piping..............................................................................................................18-19

Battery and Wiring............................................................................................................................................20

APPENDICES

Appendix A – SAE J1273 May 1986 ...........................................................................................................21-22

Additional or replacement manuals may be obtained from your Fairmont distributor. When tool is received, complete

the following record:

SERIAL NUMBER: ____________________________

DATE OF PURCHASE:_________________________

WHERE PURCHASED: ________________________

Always mention the tool’s serial number when ordering or writing about parts.

For convenience in ordering, parts are listed by part number, description and quantity. If in doubt as to part needed,

send a full description, sketch, or the part itself with the order. Assemblies are in CAPITAL letters, and include all

component parts listed directly below them and indented to the right. When assemblies can be used, order them to

save time assembling individual parts. Prior arrangements must be made before returning a tool for warranty service.

To insure correct and prompt shipment of parts, always provide the following information when ordering:

1. Quantity of each part wanted 4. Serial Number of tool

2. Part number of item 5. Preferred method of shipment: UPS or air freight

3. Description of part

A person who has not read and does not understand all operating instructions is

not qualified to operate this tool.

Failure to read and understand safety instructions may result in injury or death.