H8508 Hydraulic Impact Wrench

Greenlee / A Textron Company 84455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

Operation

1/2" Socket Drive Adapter and Sockets

(See Figure 1)

1. Inspect quick-change chuck (7). Remove any dirt or

other contamination that may have accumulated in

the chuck.

2. To insert 1/2" socket drive adapter, slide and hold

quick-change chuck (7) away from tool. Insert socket

drive adapter into chuck and release chuck.

3. USE SOCKETS APPROVED FOR IMPACT

WRENCH USE ONLY. Inspect 1/2" drive socket to

be installed. DISCARD SOCKET IF CRACKS,

CHIPS OR GOUGES ARE EVIDENT. Install socket

on socket drive adapter.

4. To remove socket drive adapter, remove socket from

adapter. Slide and hold quick-change chuck (7)

away from tool. Remove socket drive adapter.

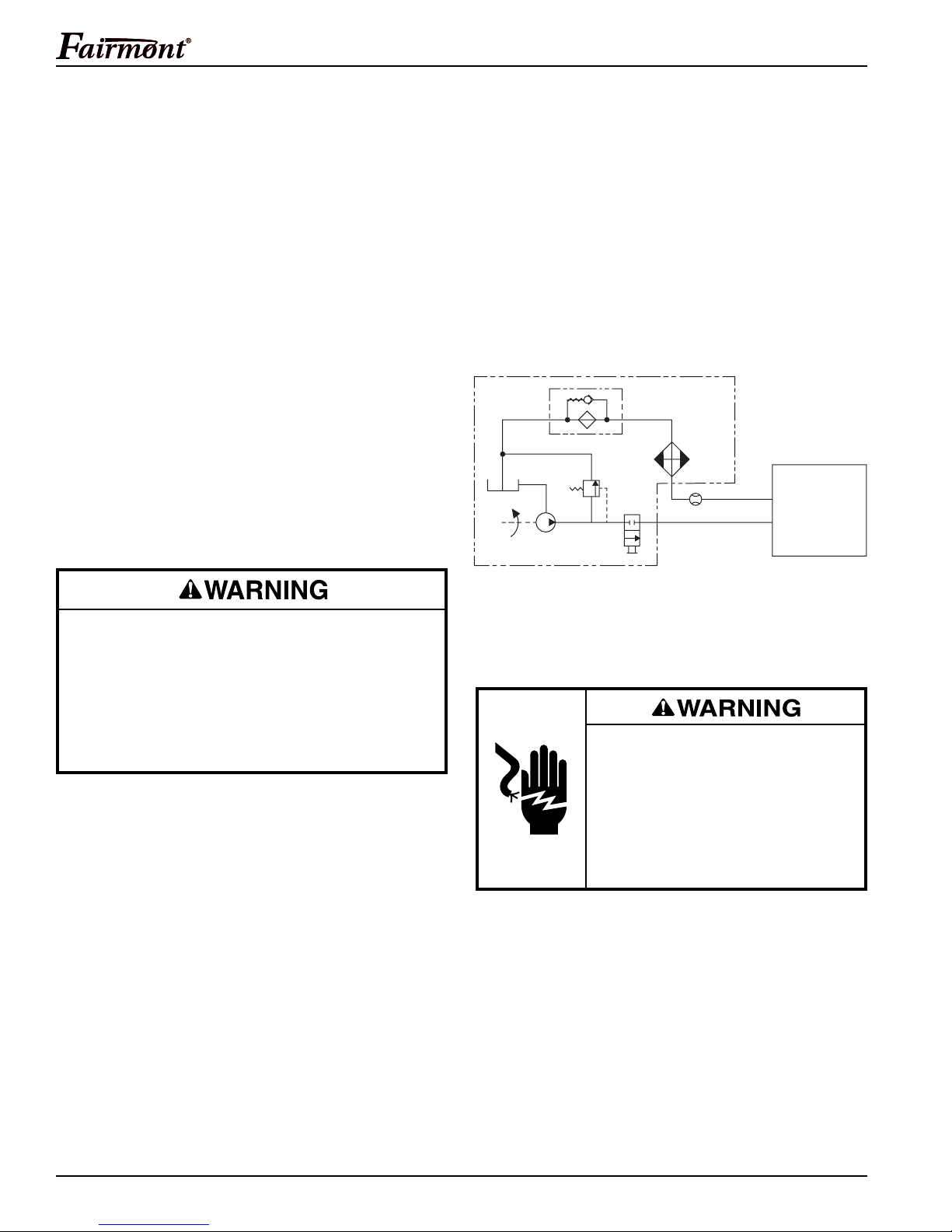

Setting Tool for Open-Center or

Closed-Center Operation

All H8508 models are equipped to allow the tool to be

used with either an open-center or closed-center hydrau-

lic power system.

Closed-Center Hydraulic System

Hold the tool as you would when operating, observe

rear of trigger spool, turn center spool in trigger spool

(Figure 1, Item 4) clockwise until spool stops. The tool is

now ready for closed-center operation.

Open-Center Hydraulic System

Hold the tool as you would when operating, observe rear

of trigger spool (Fig. 1, Item 4), turn center spool in

trigger spool counterclockwise until spool backs out to

snap-ring. The tool is now ready for open-center opera-

tion.

Open-Center/Closed-Center Hydraulic System

(for tools with serial numbers through 199)

Turn center spool in trigger spool (Figure 1, Item 4) so

spring pin indicator points upward at the letter “C”. The

tool is now ready for closed-center operations. Turn

center spool in trigger spool so spring pin indicator

points downward at the letter “O”. The tool is now ready

for open-center operation.

Impact Bits

Fairmont recommends using Greenlee Impact Style Bits.

Some impact bits with a long spiral or wide flute

spacing may not be acceptable to use with this

tool. These bits can whip or bend under sideload.

Do not use bits exhibiting these characteristics

with the H8508 Impact Wrench.

Failure to observe this warning could result in

severe injury or death.

1. Inspect the drill bit to be installed. Discard the bit if

cracks, chips or gouges are evident.

2. Inspect the quick-change chuck (7). Remove any dirt

or other contamination that may have accumulated

in the chuck (7).

3. Slide and hold quick-change chuck (7) away from

tool and remove drive shank (8).

4. Insert desired bit into hex socket of tool and release

chuck (7).

5. To remove drill bit, slide and hold quick-change

chuck (7) away from tool and remove bit.

UPC No. Hole Dia. Overall Length Hex Shank Weight

78-3310- inch mm inch mm inch mm lb g

37868 9/16 14.3 18 457 7/16 11.1 0.9 409

37869 11/16 17.5 18 457 7/16 11.1 1.1 499

37870 13/16 20.6 18 457 7/16 11.1 1.4 636

37871 15/16 23.8 18 457 7/16 11.1 1.5 681

37872 1-1/16 27.0 18 457 7/16 11.1 1.7 772

37873 9/16 14.3 22 559 7/16 11.1 1.2 545

37874 11/16 17.5 22 559 7/16 11.1 1.5 681

37875 13/16 20.6 22 559 7/16 11.1 1.8 817

37876 15/16 23.8 22 559 7/16 11.1 2.1 953

37877 1-1/16 27.0 22 559 7/16 11.1 2.2 998