855 Smart Bender®

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

9

Maintenance (cont’d)

1-1/2" to 2" Roller Support

1. Disconnect the bender from the power source.

2. Remove the 1-1/2" to 2" shoe (refer to “Changing

Shoes” in this section of the manual).

3. Refer to the “1-1/2" to 2" Roller Support Unit

Exploded View.” Use a pair of needle-nose pliers to

disconnect the springs (104) from the holes in the

side of the bender frame beneath the roller support

unit.

4. Refer to the “Main Exploded View.” Remove the

squeeze adjustment arm screw (97) and arm (74).

5. Remove the three button head cap screws (96) and

adapter sleeve (92).

6. Place one hand under the support arms (71) to

support the weight of the roller support unit.

Remove the eccentric shaft (91).

Note: You may need to rotate the eccentric shaft to

remove it.

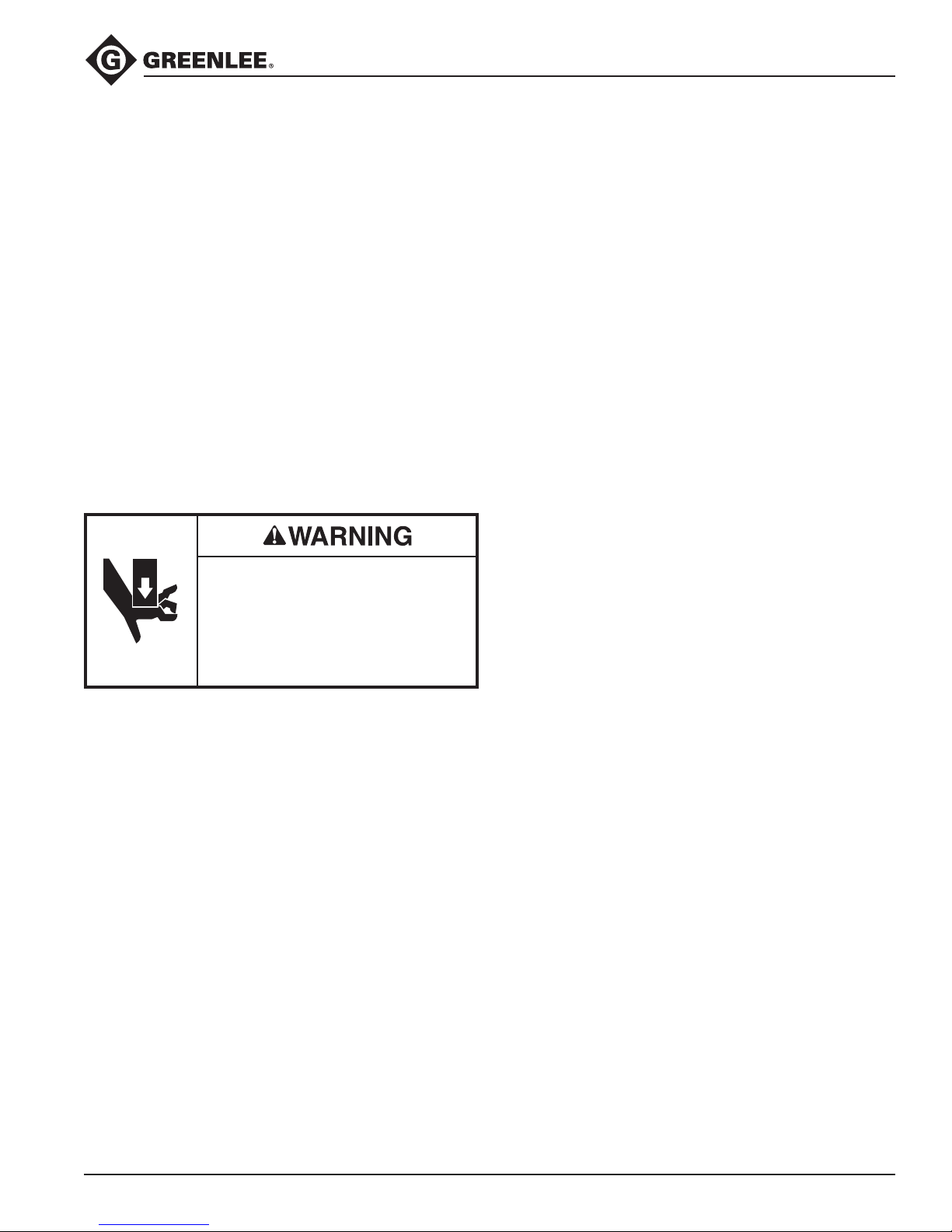

Pinch points:

Keep hands away from bending

shoe, rollers, and conduit when

bender is in use.

Failure to observe this warning could

result in severe injury or death.

7. Lift the roller support subassembly to the left and

upward.

8. On the 1-1/2" roller group:

Loosen the sleeve set screw (98) and remove the

1-1/2" pivot roller shaft (86) with grip (90). Remove

the sleeve (87).

Remove two hex head screws (93). Remove the

outer roller plate (75).

Remove the tail roller (84).

Remove all components of the split roller

assembly.

9. On the 2" roller group:

Loosen the sleeve set screw (98) and press out

the 2" pivot shaft (88). Remove the sleeve (89).

Remove the hex head screw (93). Remove one

retaining ring (95) from the tail roller shaft (83).

Remove the outer roller plate (76).

Remove the tail roller (82) and center roller (85).

Remove all components of the split roller

assembly.

•

•

•

•

•

•

•

•

10. Clean off all of the grease and dirt.

11. Inspect each item. Replace any worn, damaged,

or missing items.

12. Lubricate all working surfaces with a high-quality

grease.

13. Replace all components in reverse order, noting the

following:

On both roller groups: To ease the assembly of

the split roller subassemblies, begin by slipping

the O-rings onto the side plates. Assemble the

split roller subassemblies as shown, and then slip

the O-rings into their correct positions.

On the 2" roller group only: After replacing any

split roller components, add or remove shim

washers (99, 119, or 150) as needed.

On the 1-1/2" roller group: Install the two

Belleville washers (100) so that the inside diam-

eters contact each other.

Use Loctite®271 on the two hex head screws (93).

Torque to 55 Nm to 61 Nm (40 ft-lb to 45 ft-lb).

14. Position the roller support arms (71) as shown.

Assemble the roller groups to the support arms.

15. Reinstall the roller support unit to the bender. Keep

one hand under the support arms so they do not

drop completely below the set screw (107).

16. Insert the eccentric shaft (91).

Note: You may need to rotate the eccentric shaft to

get it to seat completely.

17. Install the adapter sleeve (92) and three button head

cap screws (96).

18. Install the adjustment arm (74) and adjustment arm

screw (97).

19. Attach the springs (104) to the holes in the side of

the bender frame beneath the roller support unit.

20. Put the bender in the horizontal bending position.

Adjust the set screw (107), if necessary, so that the

support arms (71) are centered between the front

and back plates. Engage and disengage the roller

support unit to be sure that it moves freely.

•

•

•

•