Greenlee Textron / Subsidiary of Textron Inc. 34455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

853 Quad Bender™

IMPORTANT SAFETY INFORMATION

This symbol is used to call your attention to hazards

or unsafe practices which could result in an injury

or property damage. The signal word, defined below,

indicates the severity of the hazard. The message after

the signal word provides information for preventing or

avoiding the hazard.

Hazards or unsafe practices which, if not avoided,

MAY result in injury or property damage.

Hazards which, if not avoided, COULD result in severe

injury or death.

Immediate hazards which, if not avoided, WILL result

in severe injury or death.

SAFETY

ALERT

SYMBOL

Read and understand all of the

instructions and safety information

in this manual before operating or

servicing this tool.

Failure to observe this warning will

result in severe injury or death.

• Do not expose to rain.

• Do not use in wet or damp

locations.

Failure to observe these warnings

can result in severe injury or death.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection can

result in serious eye injury from

flying debris.

Do not remove guards.

Failure to observe this warning can

result in severe injury or death.

Do not use this tool in a hazardous

environment. Hazards include

flammable liquids, gases, or other

materials. Using this tool in a

hazardous environment can result in

a fire or explosion.

Failure to observe this warning will

result in severe injury or death.

Electric shock hazard:

• Connect the power cord to a 120

volt, 20 amp receptacle on a

ground fault protected circuit only.

See Grounding Instructions.

• Do not modify the power cord or

plug.

• Inspect the power cord before

use. Repair or replace the cord if

damaged.

• Disconnect from power before

servicing.

Failure to observe this warning can

result in severe injury or death.

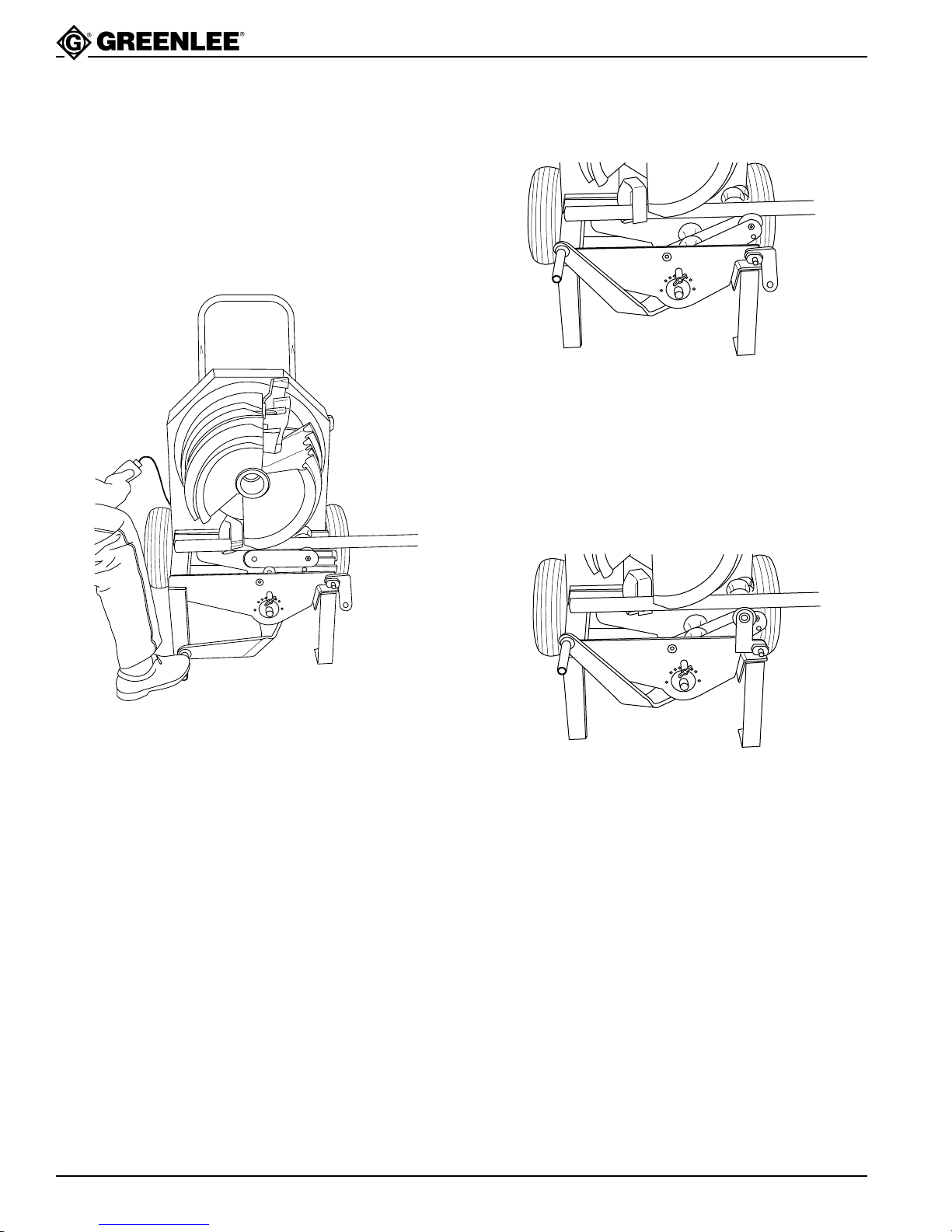

Wear protective footwear when

operating or servicing this tool.

Failure to observe this warning can

result in severe injury.