Greenlee Textron / Subsidiary of Textron Inc. 94455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

855 Smart Bender™

Operation —Standard Pendant

Set the type and size of conduit you will be bending

with the rotary selector switches located on the side

of the bender.

Failure to do so may result in the shoe rotating the

opposite direction than expected.

Bend Key: runs the shoe in the direction to bend the

conduit according to which conduit size has been

selected by the rotary size selector switch. The BEND

key functions only while it is pressed. The BEND key

ceases to function once it reaches the maximum shoe

travel or an angle stored in memory.

Jog Key: runs the shoe in the direction to bend the

conduit according to which conduit size has been

selected by the rotary size selector switch in 1/2-degree

increments. The JOG key functions any time it is

pressed until the maximum shoe travel is reached.

Unload Key: runs the shoe backwards according to

which conduit size has been selected by the rotary size

selector switch. The UNLOAD key functions when it is

pressed unless the roller support locking cam is locked

in position.

Note: The shoes can rotate a restricted amount in the

bend direction. When the maximum has been reached, the

BEND and JOG keys will not function. Use the UNLOAD

key to rotate the shoes to the proper load position.

Angle Select ▲: is used to set the desired bend angle

into memory. Pressing it for a moment increases the

present angle in memory 1 degree at a time. Holding it

down rapidly advances the memory angle.

Angle Select ▼: functions the same as the ANGLE

SELECT UP key except it decreases the angle.

Clear Key: sets the display to 00 and eliminates any

angle from memory. It will not reset the actual present

bend angle to zero.

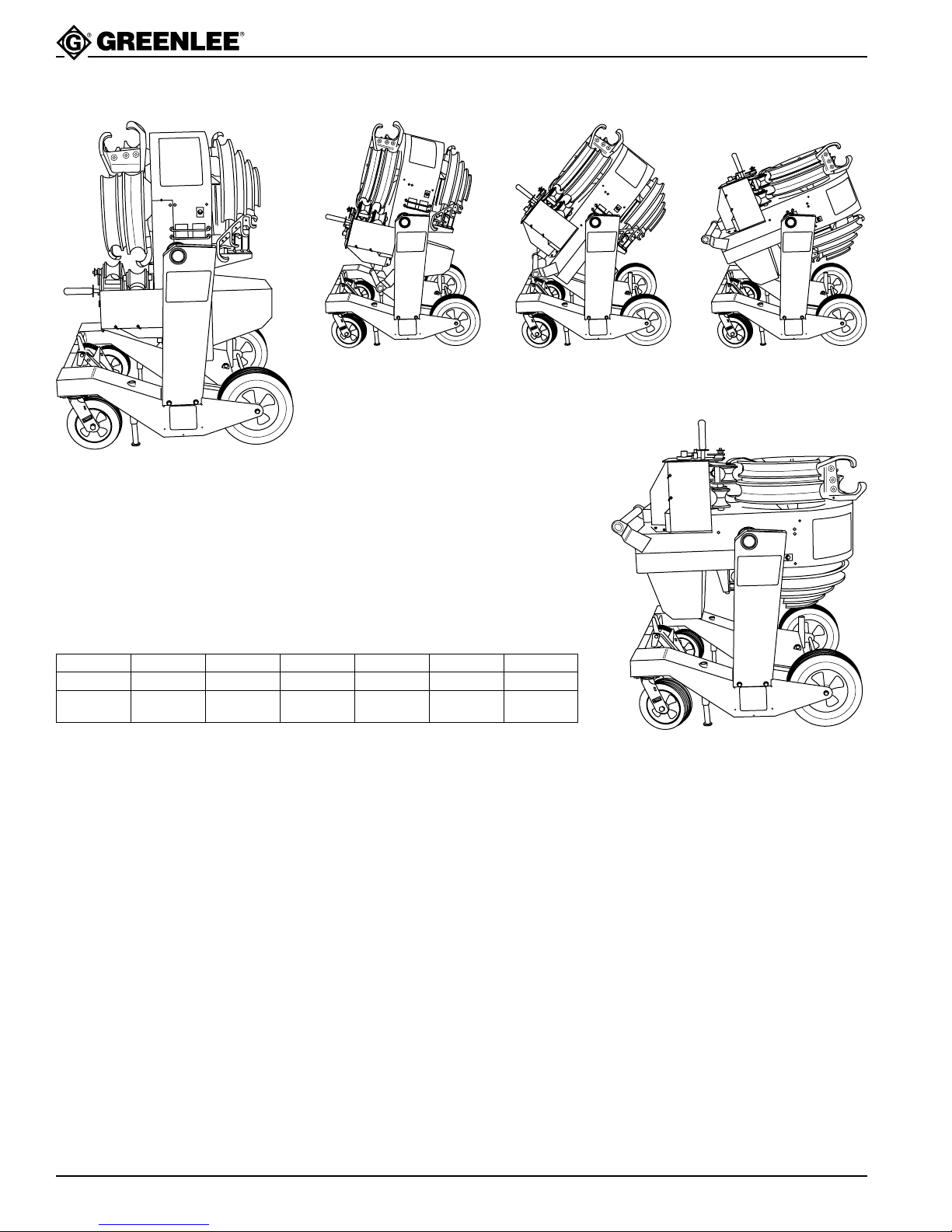

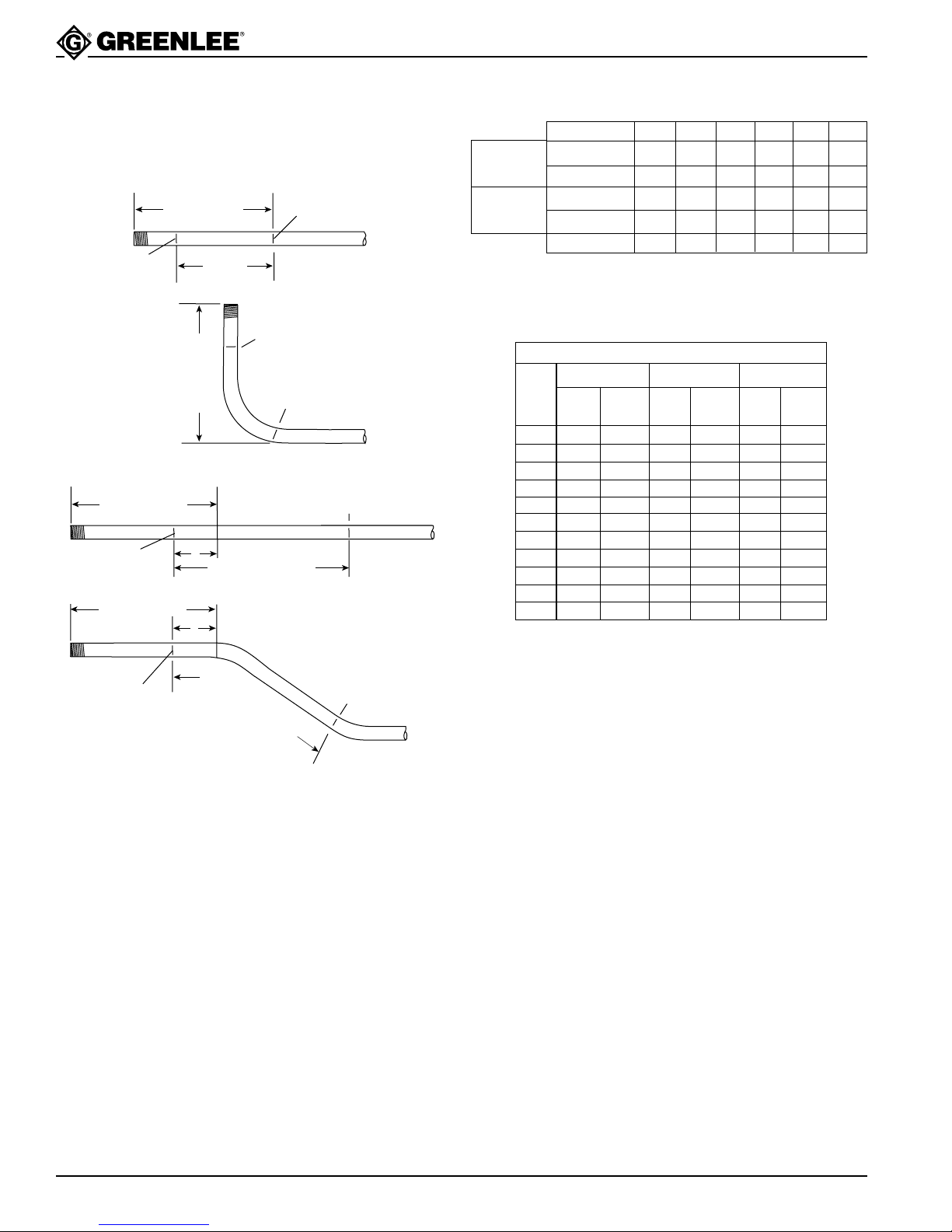

CONDUIT SIZE

CONDUIT TYPE

DECAL NO. 500 8896.7

1/2

3/4

11-1/4

1-1/2

2

DECAL NO. 500 1487.0

RIGID ALUM

PVC

IMC

EMT

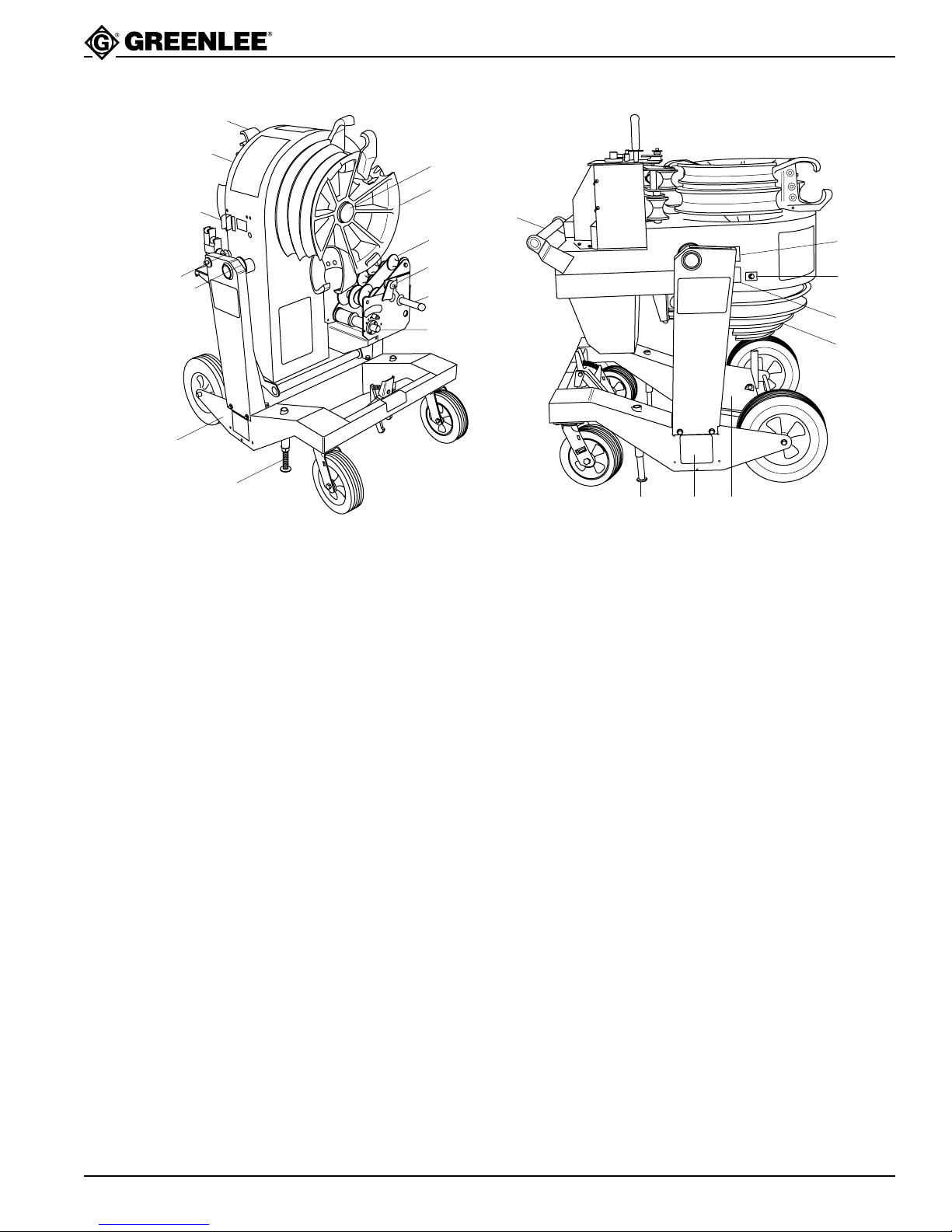

Use lifting eyes for hoisting

Lift only with bending head in a horizontal position

with the 1-1/2" and2" side up

Display: shows the actual angle the conduit has been

bent in degrees. Counting does not start until the

conduit actually starts to bend. If an angle is stored in

memory, the display shows the stored angle at all times

except while the BEND, JOG, or UNLOAD keys are

depressed and for about 2 seconds after they are

released. The display will not show angles greater than

99 or less than 0.

Upon power-up the display will show H., which indicates

that the home position must be set on the bender before

installing conduit. Press UNLOAD until the shoe hook

for the size and type of conduit selected is at the bottom

(5 o’clock position). Press BEND until the pendant

display changes from H. and starts counting. Then

press UNLOAD until the shoe rotates backwards and

stops. This is the proper load position for the selected

size and type of conduit and home position is now set.

The display will show H. each time there is a change in

conduit type setting, a change in conduit size to the

other shoe, and when power to the bender has been

interrupted.

Accuracy Adjust Mode: due to variations in conduit,

you may notice the bender consistently over or under

bending a particular size and type of conduit. The

accuracy adjustment mode allows programming correc-

tions for over and under bending conduit. Minus 9 to

plus 9 degree adjustments can be made for each size

and type of conduit. Press and hold CLEAR, then press

and hold BEND until Pr is displayed. Release controls

and adjust the degrees of bend by pressing the ANGLE

SELECT up and down controls. ANGLE SELECT UP

increases and ANGLE SELECT DOWN decreases the

bend angle for the size and type of conduit selected by

the rotary selector switches. CLEAR resets the adjust

angle to zero. Any adjust angle may be displayed by

setting the rotary selector switches to the desired size

and type of conduit. Press BEND to save the adjust

angle and exit the Adjust mode. Only changes to the

last displayed value will be saved. Changes saved are

to permanent memory in the bender and can only be

changed by reprogramming. The pendant will display

oP for two seconds when the bender returns to the

normal operating mode.

BEND

JOG

UNLOAD

ANGLE

SELECT

ANGLE

SELECT

CLEAR