12 13

led) drop in temperature. Both can influence the results as

one may lose control over the cooking process.

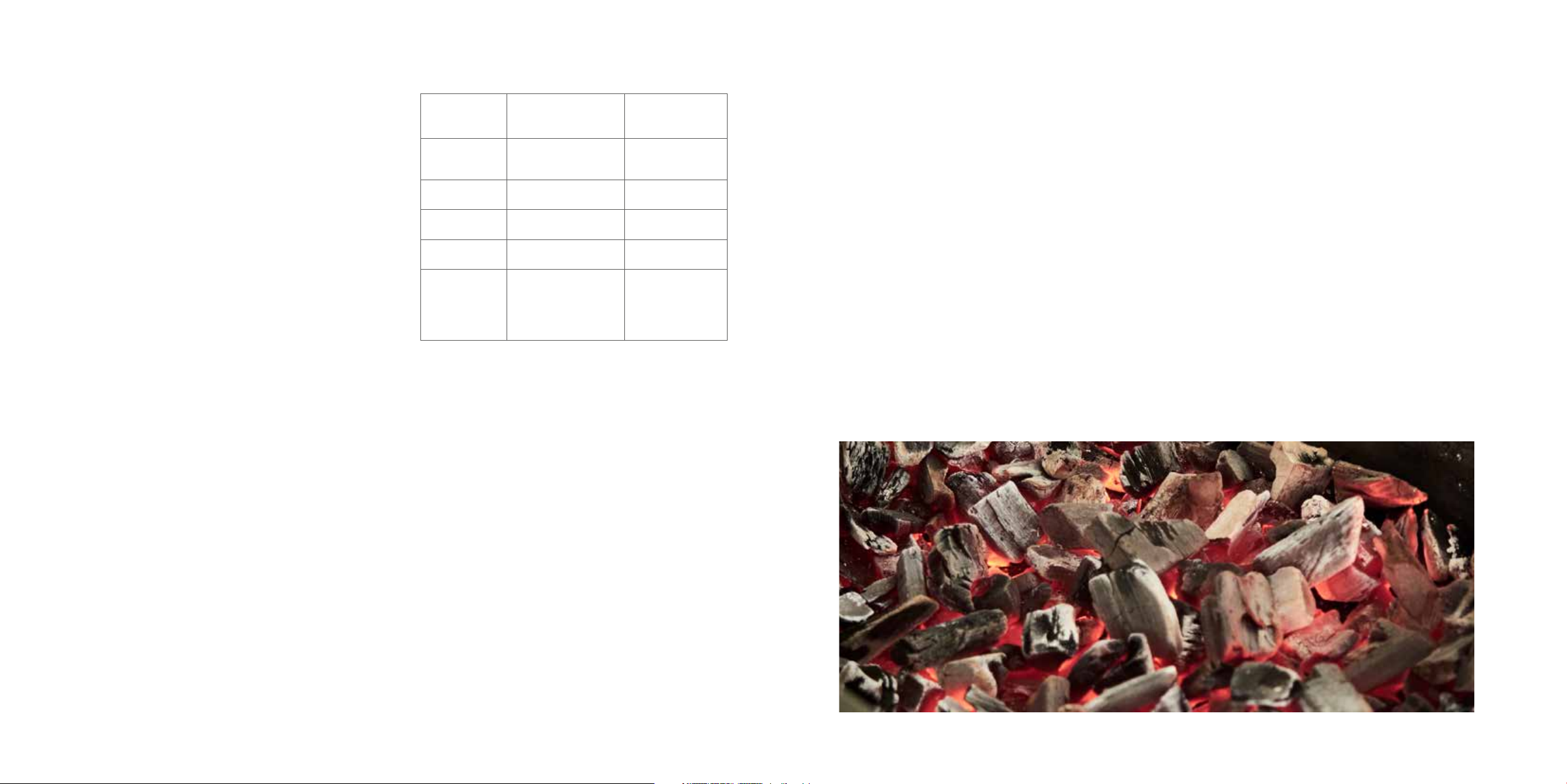

All in all the lower ash content (white residue) remains a

decisive advantage, which does not hinder the heat ra-

diation from the ember during direct grilling and ensures

that there is little ash residue overall.

In addition the grain size also plays a role. The smaller

the coal pieces are, the larger the specific (reaction) sur-

face area, which in turn means that more carbon reacts

with air at the same time and generates more heat. The

disadvantage is that during ignition, the supply of air that

drives the reaction is hindered by the denser bulk and

smaller pieces of coal burn off faster than larger ones.

Charcoal briquettes

Charcoal briquettes consist of charcoal dust which is

pressed into shape with binders and other substances.

In terms of carbon and ash content, charcoal briquettes

are inferior to „natural“ charcoal. However, charcoal

briquettes feature a longer burning time and temperatu-

re constancy.

DIN-EN 1860-2

In Germany, the minimum requirements for charcoal

and briquettes are standardized by the DIN-EN 1860-

2 standard as follows

Good quality charcoal clearly exceeds the requirements

of the DIN-EN 1860-2 standard and achieves carbon

contents of over 85% with an ash content of less than

2%. The same applies to good charcoal briquettes.

Burning time and heat

The burning time depends on the type and grain size

of the charcoal or briquettes used, the grill used and

the amount of air supplied to the charcoal grate. As

already noted, it is generally true that charcoal briquet-

tes burn slower than charcoal. Charcoal briquettes are

therefore more suitable for slower indirect grilling than

for fast direct grilling. Also mixtures of charcoal and

briquettes can be the means of choice.

As a guideline, good charcoal on the Kenia is glowing

through after about 15 minutes and after reduction of

the air supply remains ready for grilling for a good

hour, whereby the maximum temperature of 300-500°

C is only maintained for the first 30 minutes and then

Test criteria Requirements

Charcoal

Requirements

Charcoal briquettes

Carbon content > 75 % > 60 %

Ash content <8 % <18 %

Humidity <8 % <8 %

bulk density 130kg/m3 -

Grain size

between 0 und 150 mm

max. 10 % >80 mm

at least 80 % >20 mm

max. 7% 0 – 10 mm

max. 10% >20mm

higher than direct imports would suggest. The WWF‘s

2017 market analysis has confirmed this: 40 percent

of the charcoal tested came from tropical or subtropical

countries.

Grillwerk therefore recommends the use of charcoal

from verifiably sustainable production such as FSC and

PEFC certified products. The WWF charcoal market

analysis also offers insights to products that should not

be purchased.

Product recommendations

Grillwerk particularly recommends products from Profa-

gus (www.profagus.de) and Nero (www.nero-grillen.

de). Charcoal and briquettes from these manufacturers

exceed the requirements of the DIN standard, come

from sustainable production and are FSC or PEFC

certified.

1https://www.destatis.de/DE/PresseService/Presse/Pressemitteilungen/zdw/2018/PD18_12_p002.html.

2http://www.wwf.de/fileadmin/fm-wwf/Publikationen-PDF/WWF_Holzkohle_Marktanalyse_Deutschland_2017.pdf.

drops. For charcoal briquettes, these times should be

approximately doubled; in addition, the temperature

attainable with charcoal briquettes remains below the

temperature attainable with charcoal.

Environmental protection

Grillwerk strongly advocates not to use charcoal and

charcoal briquettes from non-sustainable forestry, in par-

ticular products that originate from rainforest logging.

According to the Federal Statistical Office (Destatis),

around 215,000 tons of charcoal were imported

to Germany in 2017. The most important supplier

countries were Poland (79 000 tons), Paraguay (32

000 tons) and the Ukraine (23 000 tons). According

to the WWF, Poland itself imports a lot of charcoal

from Nigeria and Paraguay. It can be assumed that

the proportion of tropical wood-containing charcoal is