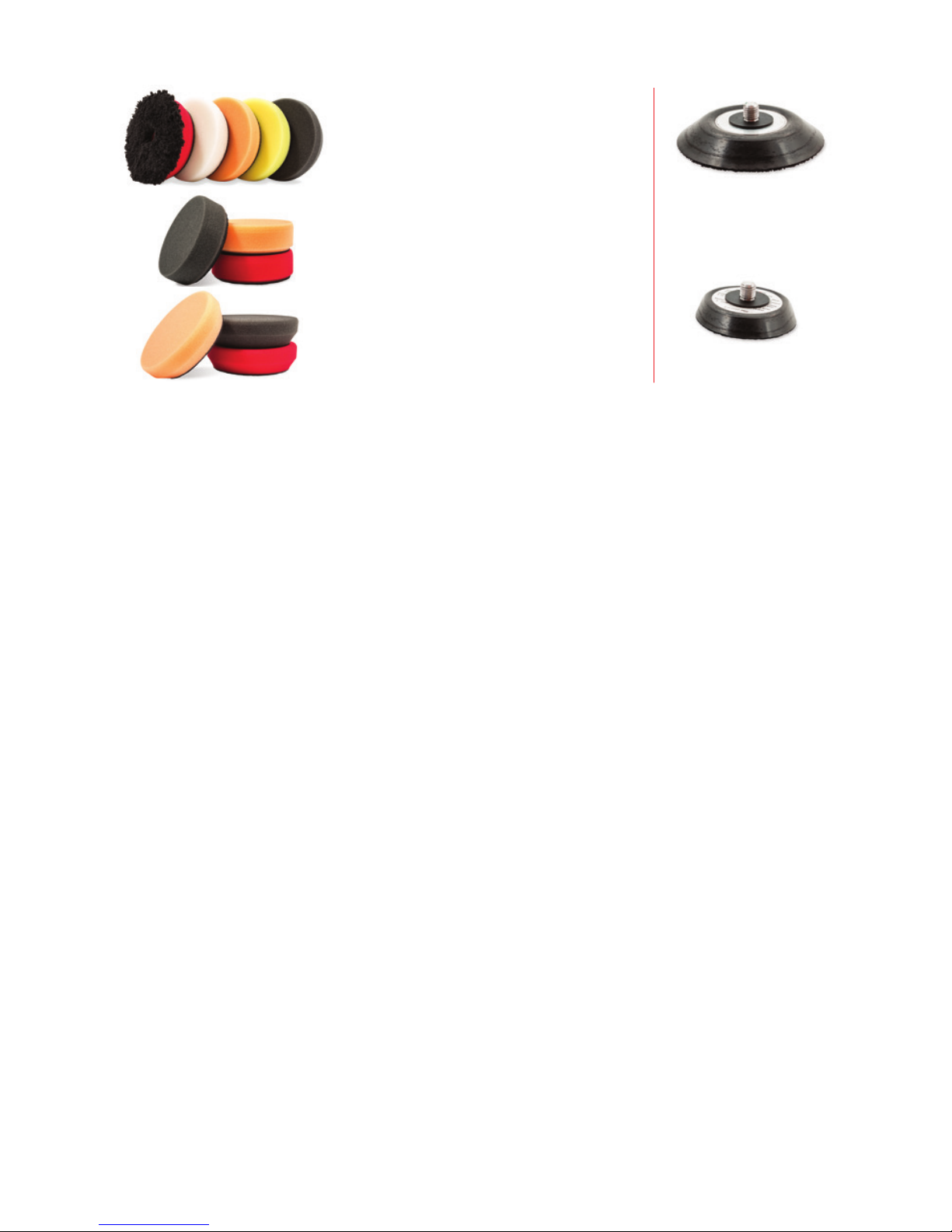

3” BOSS Pads

BMF3 BOSS 3” Microfiber Pads

B110F3 BOSS 3” FAST Correcting Foam Pads

B120F3 BOSS 3” Correcting Foam Pads

B130F3 BOSS 3” Perfecting Foam Pads

B140F3 BOSS 3” Finishing Foam Pads

9. THE BOSS™AIR Micro Rotary Polisher Accessories

3” Foam Pads

11241 3” Orange Foam Correcting Pads, Set of 3

11274 3” Black Foam Finishing Pads, Set of 3

11263 3” Red Foam Waxing Pads, Set of 3

4” Foam Pads

11266 4” Orange Foam Correcting Pads, Set of 3

11275 4” Black Foam Finishing Pads, Set of 3

11281 4” Red Foam Waxing Pads, Set of 3

BR2BP 2” BOSS AIR

Rotary Backing Plate

BR3BP 3” BOSS AIR

Rotary Backing Plate

Product Use

All statements, usage recommendations, and technical information contained in this manual are

based on tests or development that Griot’s Garage has deemed reliable. However, many factors beyond

Griot’s Garage’s control can affect the use and performance of this Griot’s Garage product in a certain

application, including conditions under which the Griot’s Garage product is used and the time and

environmental conditions in which the product is expected to perform. Since these factors are uniquely

in the user’s knowledge and control, it is critical that the user evaluate the Griot’s Garage product to

determine whether it is suitable for a particular purpose and the user’s method of application.

Warranty

• Griot’s Garage Lifetime Guarantee - Griot’s Garage will repair or replace any defective tool, without

charge, due to faulty materials or workmanship for the working life of the tool, subject to certain

exclusions below.

• Six Month Satisfaction Guarantee - We want you to enjoy our quality product and have fun with it! If

you’re not 100% satisfied for any reason within six months of purchase, return it to point of sale with

proof of purchase for a full refund or credit.

• Two Year Comprehensive Warranty - With online warranty registration, Griot’s Garage will facilitate

replacement of worn parts caused by normal use, without charge, anytime during the two years from

date of purchase. We will repair it or replace it, or credit purchase price if we are able to do neither.

Exclusions

• The Two Year Comprehensive Warranty is void should your tool experience damage caused by failure

to follow the recommended maintenance, misuse, alteration or abuse.

• Griot’s Garage Lifetime Guarantee does not cover damage caused by failure to follow recommended

maintenance, misuse, alteration or abuse. Normal wear and tear is not considered a defect, therefore

part failure which may occur as the result of ordinary use is excluded from coverage.

• Griot’s Garage is not responsible for any incidental or consequential damages.

Disclaimer

Limitation of Liability. In no event shall the monetary liability of company exceed amounts that have

actually been paid to company. Company shall not be liable for consequential, indirect, special, or

incidental damages under any circumstances, even if advised in advance of the possibility of such

damages.

Answers To Your Questions

To order additional BOSS Best Of Show System products, or for a complete selection of Griot’s Garage

products, please call us toll-free at 800-345-5789, email us at sales@griotsgarage.com, or go to www.

griotsgarage.com/BOSS.

Have fun in your garage!®

Griot’s Garage, Inc. • 3333 South 38th Street • Tacoma, WA 98409

800-345-5789 • www.griotsgarage.com

©2016 Griot’s Garage Inc.