Table of Contents

INTRODUCTION............................................... 2

BVcjVa6XXjgVXn########################################### '

8dciVXi>c[d####################################################'

>YZci^[^XVi^dc################################################### (

<,.)*BVX]^cZ9ViVH]ZZi########################## )

<,.)+BVX]^cZ9ViVH]ZZi########################## +

SECTION 1: SAFETY....................................... 8

HV[Zin>chigjXi^dch[dgBVX]^cZgn################## -

6YY^i^dcVaHV[Zin[dg9g^aaEgZhhZh############### &%

SECTION 2: CIRCUIT REQUIREMENTS ...... 11

&&%KDeZgVi^dc############################################ &&

SECTION 3: SET UP ...................................... 12

>iZbhCZZYZY[dgHZiJe############################# &'

JceVX`^c\#################################################### &'

>ckZcidgn######################################################&(

=VgYlVgZGZXd\c^i^dc8]Vgi####################### &)

8aZVcJe###################################################### &*

H^iZ8dch^YZgVi^dch###################################### &*

8dajbcVcY7VhZ######################################## &+

IVWaZ7gVX`Zi############################################### &+

=ZVYhidX`#################################################### &,

9dlc[ZZY=VcYaZh##################################### &-

9g^aa8]jX`VcY6gWdg################################### &-

IZhiGjc###################################################### &.

Bdjci^c\###################################################### &.

GZXdbbZcYZY6Y_jhibZcih######################## '&

SECTION 4: OPERATIONS ........................... 22

Hl^iX]$HV[Zin@Zn######################################## ''

>chiVaa^c\$GZbdk^c\9g^aa7^ih####################### ''

8]ddh^c\HeZZYh######################################### '(

8]Vc\^c\HeZZYh######################################## ')

9g^aa^c\########################################################## '*

9Zei]Hide################################################### '+

IVWaZ6Y_jhibZcih####################################### '+

=ZVY6Y_jhibZcih######################################## '-

SECTION 5: ACCESSORIES......................... 29

SECTION 6: MAINTENANCE......................... 31

<ZcZgVa########################################################(&

8aZVc^c\#######################################################(&

JceV^ciZY8Vhi>gdc##################################### (&

AjWg^XVi^dc################################################### (&

K"7Zaih######################################################### (&

SECTION 7: SERVICE ................................... 32

6WdjiHZgk^XZ############################################### ('

IgdjWaZh]ddi^c\########################################### ('

9Zei]Hide8Va^WgVi^dc################################# ()

;ZZYH]V[iHeg^c\IZch^dc########################## ()

:aZXig^XVa8dbedcZcih################################# (*

<,.)*$<,.)+L^g^c\9^V\gVb#################### (+

<,.)*$<,.)+BV^cEVgih7gZV`Ydlc######### (,

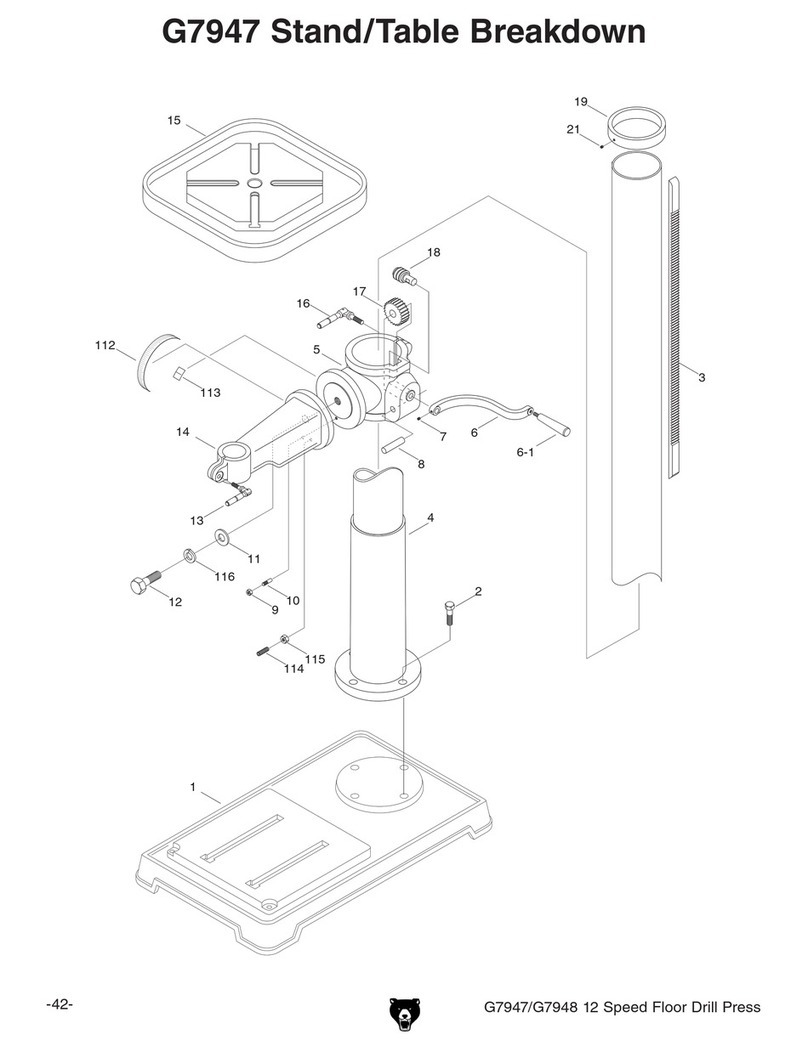

<,.)*8dajbc7gZV`Ydlc########################## (.

<,.)+8dajbc7gZV`Ydlc########################## )%

HV[ZinAVWZaEaVXZbZciVcYEVgihA^hi######## )'

WARRANTY AND RETURNS ........................ 45