Model T33901/T33902 (Mfd. Since 07/23) -7-

The information contained herein is deemed accurate as of 12/27/2023 and represents our most recent product specifications.

Due to our ongoing improvement efforts, this information may not accurately describe items previously purchased. PAGE 2 OF 2

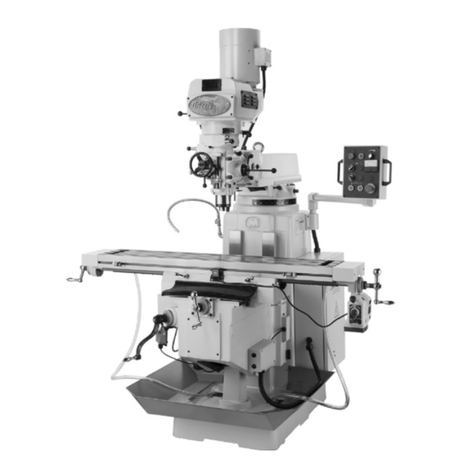

Model T33901

Spindle Information

Distance From Spindle to Base........................................................................................................... 23-3/8 in.

Quill Diameter......................................................................................................................................... 1.85 in.

Table Information

Max. Table Tilt (Left/Right)................................................................................................................ 0 - 45 deg.

Table Swing.......................................................................................................................................... 360 deg.

Table Swivel Around Center................................................................................................................. 360 deg.

Table Swivel Around Column............................................................................................................... 360 deg.

Table Length........................................................................................................................................ 11-1/4 in.

Table Width......................................................................................................................................... 11-1/4 in.

Table Thickness.................................................................................................................................. 1-1/16 in.

Vertical Table Travel............................................................................................................................ 14-3/8 in.

Number of T-Slots............................................................................................................................................ 4

T-Slot Size.............................................................................................................................................. 9/16 in.

Floor-To-Table Height.................................................................................................................... 9-5/8 - 24 in.

Construction

Table....................................................................................................................... Precision-Ground Cast Iron

Column....................................................................................................................................................... Steel

Spindle Housing................................................................................................................................... Cast Iron

Head.................................................................................................................................................... Cast Iron

Base..................................................................................................................................................... Cast Iron

Paint Type/Finish....................................................................................................................... Powder Coated

Other Related Information

Base Length............................................................................................................................................... 18 in.

Base Width.......................................................................................................................................... 10-1/2 in.

Column Diameter................................................................................................................................... 3-1/8 in.

Quill Flange/Collar Diameter................................................................................................................. 2-1/8 in.

Quill Hold Type...................................................................................................................... Slotted Set Screw

Depth Stop Type................................................................................................ Threaded Rod w/Positive Stop

Has Work Light............................................................................................................................................. Yes

Light Socket Type................................................................................................................................ LED 12V

Maximum Bulb Wattage................................................................................................................................ 3W

Has Laser Guide.......................................................................................................................................... Yes

Laser Classification................................................................................................................................ Class II

Laser Wavelength................................................................................................................................... 650 nm

Laser Maximum Output.............................................................................................................................. 1mW

Other Specifications:

Country of Origin ................................................................................................................................................ China

Warranty ........................................................................................................................................................... 1 Year

Approximate Assembly & Setup Time ........................................................................................................ 30 Minutes

Serial Number Location ................................................................................................................... Machine ID Label

ISO 9001 Factory .................................................................................................................................................. Yes

Features:

Hand-Crank Enabled Rack and Pinion Table Elevation

11-1/4" x 11-1/4" Cast Iron Table w/Four 9/16" T-Slots

Built-In LED Light

Adjustable Class II Laser Sights

3-1/4" Spindle Travel

360 Deg. Table Positioning Around Column

Cast Iron Base w/Two 5/8" T-Slots, 5-1/4" on Center

12 Speed Settings: 340, 500, 530, 660, 740, 790, 1380, 1420, 1680, 1860, 2200, 2860 RPM

JT3 Key Chuck 1/8" - 5/8"