Maintenance

Manual

A6ML0260 - KS MK3 & UCR MK3 Manual

Table of Contents

Manual content disclaimer ......................................................................................................................4

1. Introduction .........................................................................................................................................5

2. Safety..................................................................................................................................................6

2.1 Hazards.........................................................................................................................................6

2.2 Precautions ...................................................................................................................................6

2.3 Cleaning solutions.........................................................................................................................7

2.3.1 Type .......................................................................................................................................7

2.3.2 Use of cleaning solutions.......................................................................................................7

2.4 Safe practices ...............................................................................................................................8

2.5 Noise emission..............................................................................................................................8

2.6 Environmental ...............................................................................................................................9

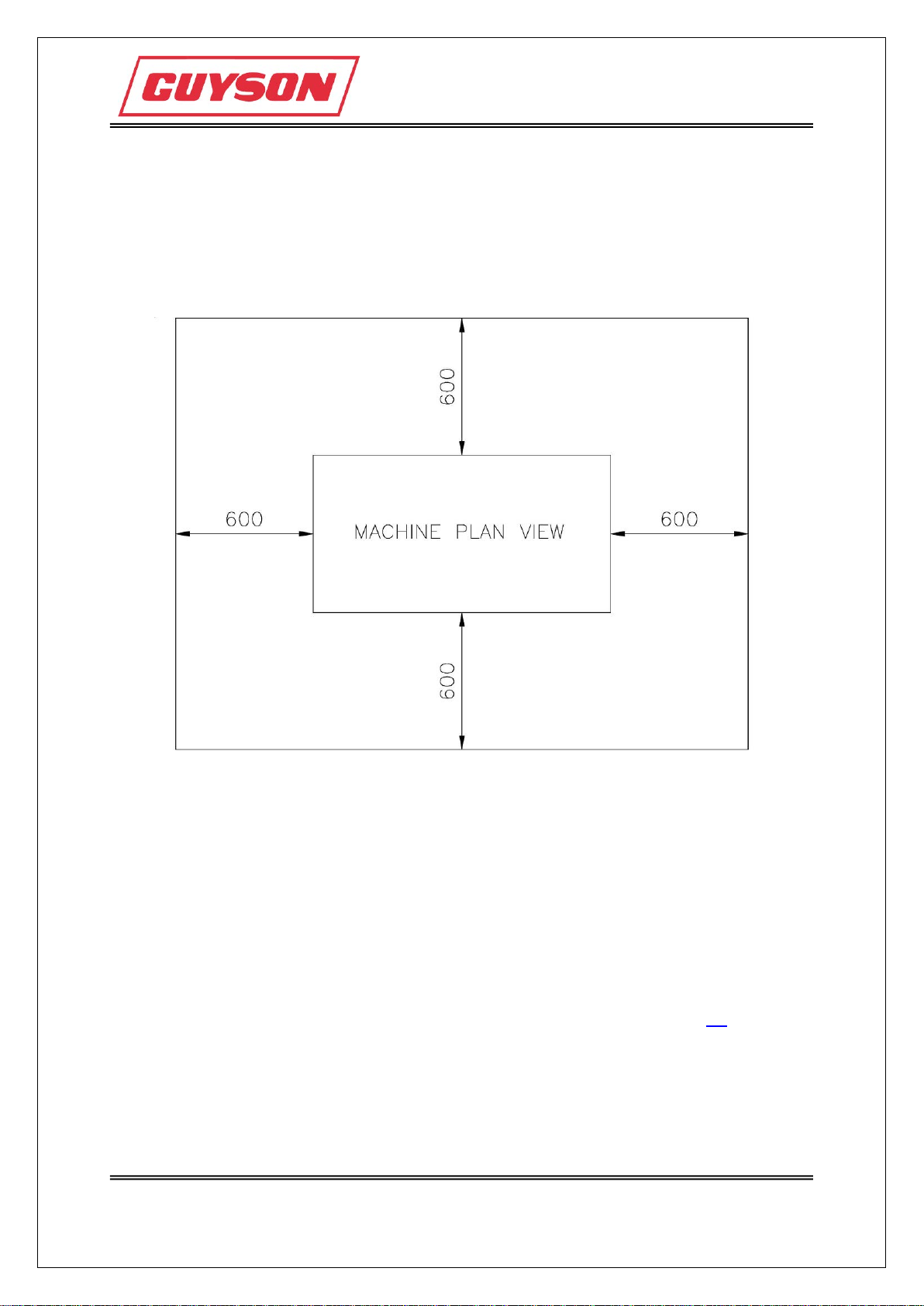

3. Installation and siting.........................................................................................................................10

3.1 Isolation and switching devices (3 phase units)..........................................................................11

3.1.1 3 phase units with flexible armoured cable..........................................................................11

3.2 Further installation for units with an external ultrasonic generator .............................................12

4. Operating instructions.......................................................................................................................13

4.1 Filling of the unit..........................................................................................................................13

4.2 Control system ............................................................................................................................14

4.2.1 Layout of the membrane panel display................................................................................14

4.2.2 LED status and fault indication ............................................................................................15

4.2.3 LCD display screens ............................................................................................................16

4.3 Start up........................................................................................................................................18

4.4 Operation ....................................................................................................................................19

4.4.1 Using baskets.......................................................................................................................19

4.4.2 Starting the ultrasonics.........................................................................................................19

4.5 Setting the heating temperature..................................................................................................20

4.6 Setting the sonics time................................................................................................................21

4.7 Shutdown ....................................................................................................................................22

4.8 Ancillary parts..............................................................................................................................22

5. Description ........................................................................................................................................23

5.1 General........................................................................................................................................23

5.2 The KS MK3 range of ultrasonic cleaning tanks.........................................................................24

5.2.1 KS MK3 range technical specification..................................................................................25

5.3 The UCR MK3 range of ultrasonic clean and rinse tanks...........................................................26

5.3.1 UCR MK3 range technical specification...............................................................................27

5.4 Optional pumping and filtration unit ............................................................................................28

5.5 Baskets........................................................................................................................................29

6. Electrical circuit and control systems................................................................................................30

6.1 Power requirements table...........................................................................................................30

6.2 Transducers ................................................................................................................................30

6.3 Thermal shock.............................................................................................................................31

6.4 Fuse replacement (on single phase units)..................................................................................32

6.5 Resetting of MCB's (on 3 phase units) .......................................................................................33

7. Cleaning solutions.............................................................................................................................34

8. Maintenance......................................................................................................................................35

8.1 Safety precautions ......................................................................................................................35

8.2 Routine preventative maintenance .............................................................................................36

8.2.1 Daily .....................................................................................................................................36

8.2.2 Weekly..................................................................................................................................37

8.2.3 Monthly.................................................................................................................................37

8.2.4 Six monthly...........................................................................................................................37

8.2.5 General.................................................................................................................................37

8.3 Draining and cleaning the plant ..................................................................................................38