- 1 -

Content

1 Introduction........................................................................................................................ 2

1.1 Notation and symbols......................................................................................................... 2

1.2 Intended use....................................................................................................................... 2

1.3 System requirements.......................................................................................................... 2

1.4 License terms...................................................................................................................... 3

2 Installation .......................................................................................................................... 4

2.1 Preparation of the robot..................................................................................................... 4

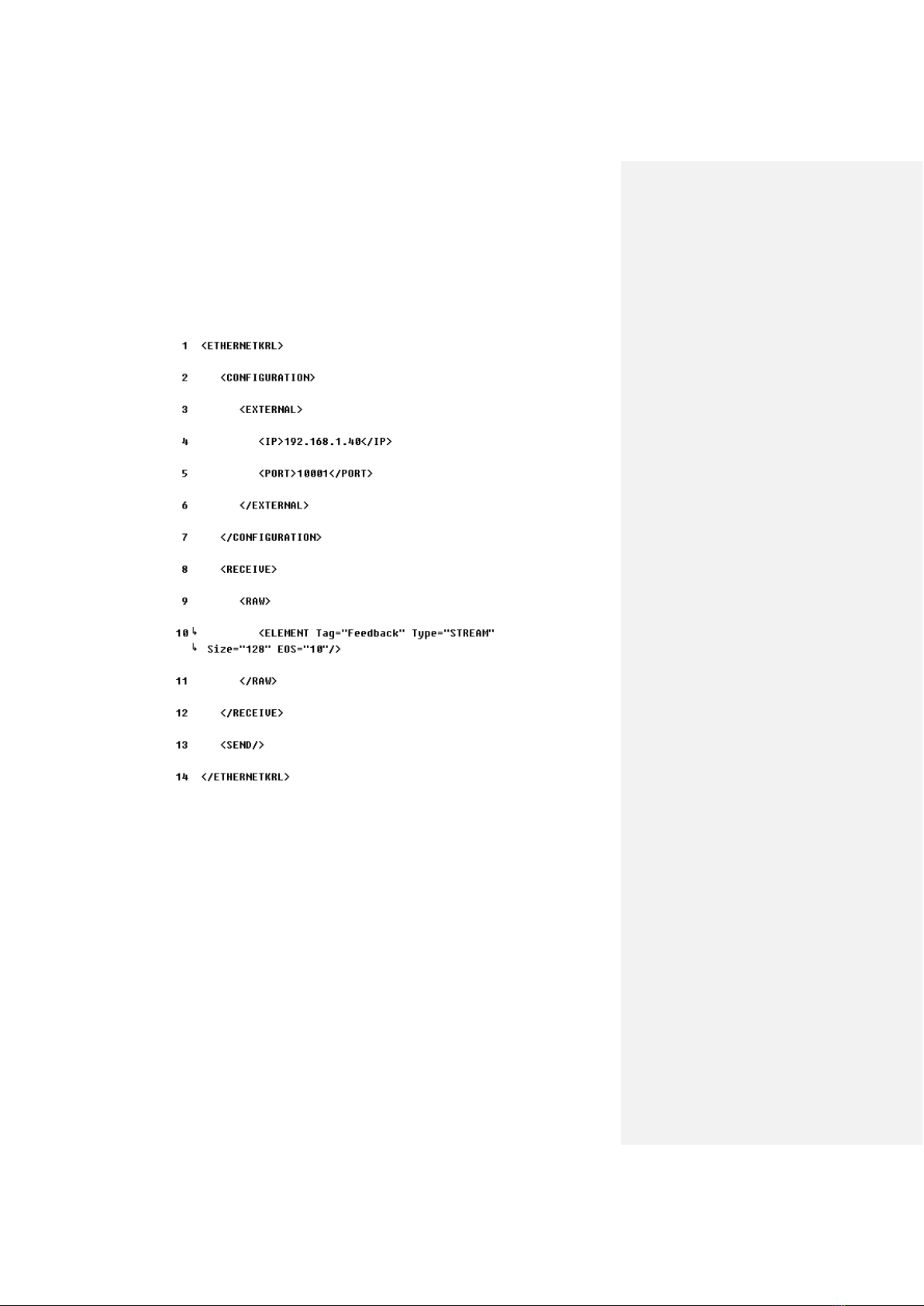

2.2 Configuration of the XML file.............................................................................................. 5

2.3 Installing the software ........................................................................................................ 6

2.4 Behavior in case of error..................................................................................................... 7

3 Command Reference .......................................................................................................... 8

3.1 Establish connection - CONNECT........................................................................................ 9

3.2 Activate device - ENABLE.................................................................................................. 10

3.3 Query grab state - GETSTATE............................................................................................ 11

3.4 Deactivate device - DISABLE ............................................................................................. 12

3.5 Referencing the gripping module - HOME........................................................................ 13

3.6 Gripping the workpiece - GRIP.......................................................................................... 14

3.7 Simultaneous gripping of workpieces - MGRIP................................................................. 15

3.8 Release workpiece - RELEASE ........................................................................................... 16

3.9 Simultaneous release of workpieces - MRELEASE............................................................ 17

3.10 Parameterize gripping recipes - SETGRIPCFG................................................................... 18

3.11 Verify device types - DEVASSERT...................................................................................... 19

3.12 Query of position and sensor values - VALUE................................................................... 20

3.13 Control gripping force retention - CLAMP........................................................................ 21

3.14 Control of the LED display - LED........................................................................................ 22

3.15 Terminating the connection of GRIPLINK and robot - DISCONNECT................................ 23

Gripping state ................................................................................................................... 24

Error numbers and ways to fix them ................................................................................ 25