24

DECLARATION OF CONFORMITY:

GYS certifies that the cutter complies with regulations 89/392/EEC, amended 91/36/EEC.

PRECAUTIONS AND WARNING BEFORE USE

To reduce the risk of physical damage, all persons operating, installing, servicing, repairing, maintaining, or replacing

accessories, as well as those who work near the tool, must read and understand these instructions.

Possible risks from power supply and connections

- Pressurized air can cause serious damage.

- Always stop the air distribution and disconnect the tool from the network to replace accessories, repair it or if you are not

using it.

- Do not direct the air jet at other people or yourself; always use the tool at a safe distance from people near the work

area.

- Whipping of pipes can cause serious damage; check pipes and connections carefully for loss or breakage.

- Do not use the quick-change couplings on the tool, as they may cause the tool to become heavy and loose due to

vibration

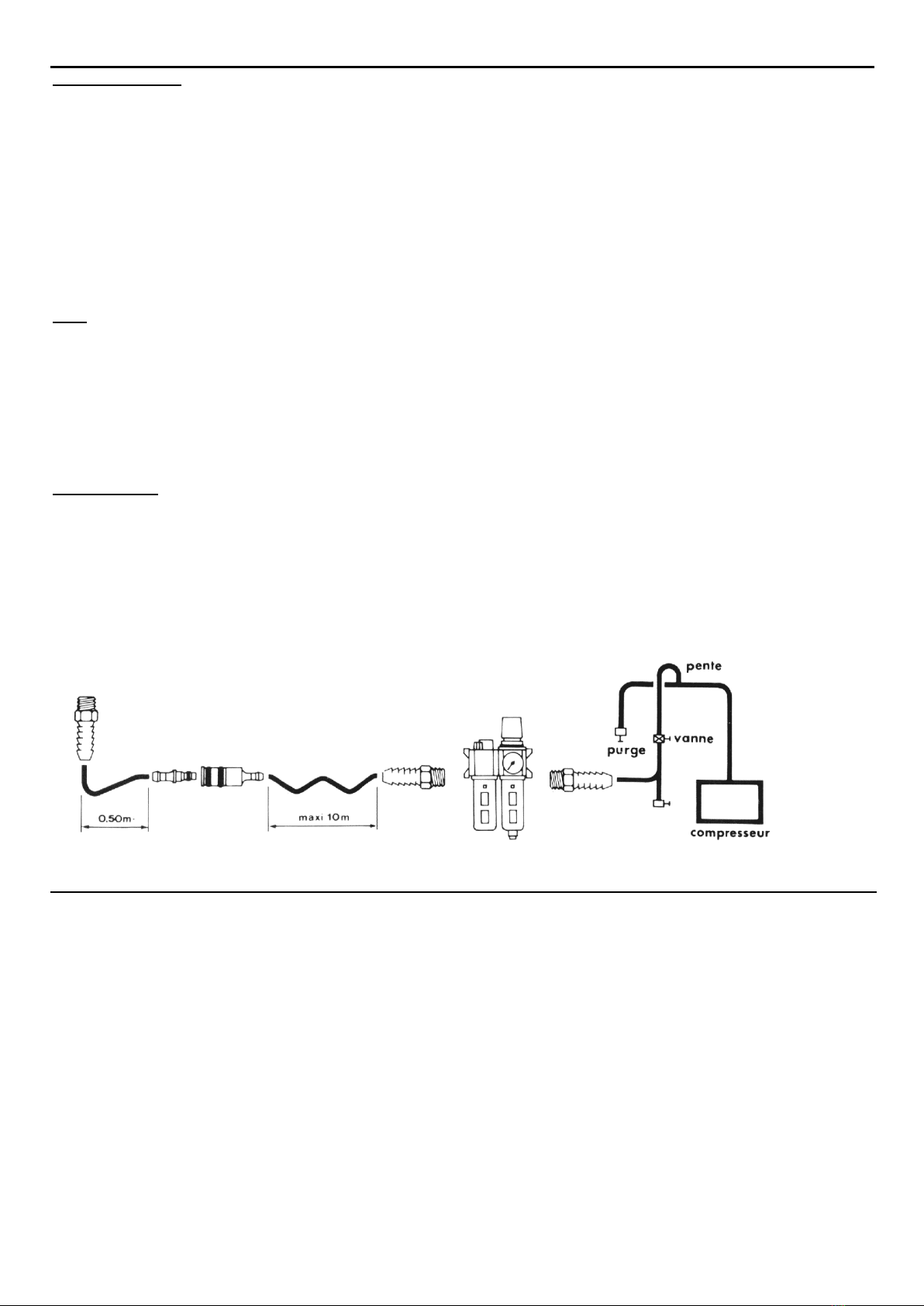

- Read the instructions for correct assembly.

- Whenever you use universal swivel couplings, use a locking pin.

• Do not exceed the maximum limit of 6/7 air pressure of the value indicated on the air tool insert.

- Handle hoses and connectors with care. Do not transport the tool by handling it by the pipe. Do not pull it by force to

disconnect it from the air supply. Keep pipes away from heat sources, lubricants and sharp edges. - Check the hoses for

wear before use. Check that all connections are secure.

Risks caused by fragments

- Always use eye and face protection when using the tool.

- Smaller fragments could also cause eye damage and blindness.

- The explosion of pneumatic tools can cause serious damage.

How to avoid the risk of becoming entangled

- Keep a suitable distance from working drills, blades, moving tools, etc.

- Do not wear rings or loose clothing.

- When you are near the tool and its accessories, pay attention to the hair as it could get tangled.

Risks caused by operation

• Avoid direct contact with the shaft and its accessory if they are in motion to prevent cutting.

• Put protective gloves on your hands.

• Do not modify the tool and its accessories.

- Operators and maintenance personnel must be physically able to manage the power of the tool and monitor the

necessary operations.

• Do not force the tool; if you use it at the speed for which it was designed, its performance will be better.

Dangers caused by working conditions

- Slipping, tripping and falling are the main causes of accidents.

- The high noise level can cause permanent damage to hearing. Employers and occupational safety bodies recommend the

use of ear protection.

- Keep your body in balance and firmly on your feet. Repetitive work movements, unusual positions and exposure to

vibration can be harmful to your hands and arms. In case of numbness, tingling, pain or pallor, stop using the tool and see

a doctor.

- This tool is not suitable for use in hazardous areas.

Safety standards for the use of the tool.

• Handle the cutter with care to ensure prolonged performance over time.

- Wear eye and ear protection, a half mask and protective gloves when using the tool.

• Use the cutter in ventilated areas.

• Do not use the tool in hazardous areas and use it away from combustible materials; contact of the tool with metals

produces sparks.

- Do not handle the device by the hose.

- Abrasives heat up during use. Allow them to cool before handling them. Disconnect the air hose when changing or

adjusting.