HAC-MLW Metering Module User Manual V1.0

Content

1.

Overview.....................................................................................................................................................................4

2.

Meter Module Feature.................................................................................................................................................4

2.1.

Electrical characteristics.................................................................................................................................. 4

2.2

Feature Description...........................................................................................................................................4

2.3

Data reporting................................................................................................................................................... 4

2.4

Power management...........................................................................................................................................4

2.5

Measurement.....................................................................................................................................................5

2.6

Power-down storage......................................................................................................................................... 5

2.7

Magnetic attack detection................................................................................................................................. 5

2.8

Monthly and yearly frozen data storage........................................................................................................... 5

2.9

The valve will be closed when the power is off............................................................................................... 5

3.

Meter module structure and interface definition......................................................................................................... 5

3.1.

Module structure dimension............................................................................................................................ 5

3.2.

Interface definition...........................................................................................................................................6

4.

Instruction of production test tool................................................................................................................................7

5.

Instructions of meter module...................................................................................................................................... 7

6.

Precautions................................................................................................................................................................... 8

7.

Instruction of Production Test Tool.............................................................................................................................9

7.1.

Tool list............................................................................................................................................................ 9

7.2.

Device connection.............................................................................................................................................9

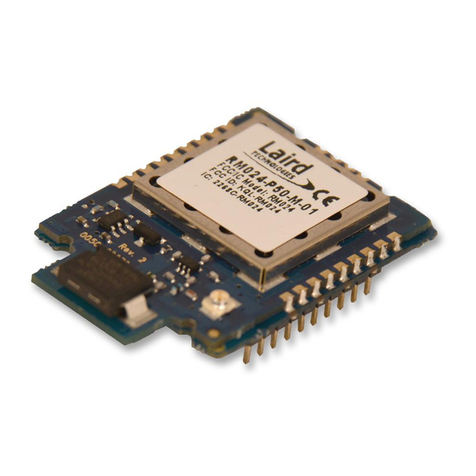

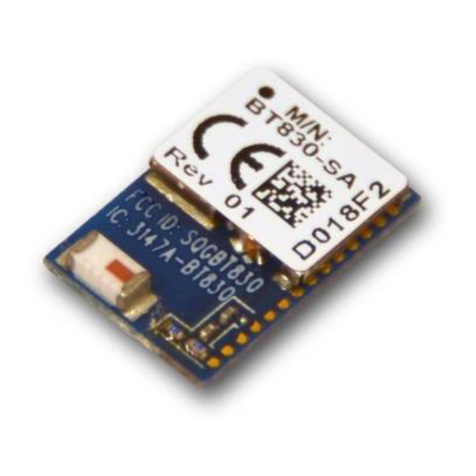

7.2.1.

Wireless communication device connection......................................................................................... 9

7.2.2.

Infrared communication device connection........................................................................................ 10

7.2.3.

Meter data acquisition (wireless communication mode ).................................................................. 10

7.2.4 Supported software.............................................................................................................................. 12

7.2.5.

Software installation............................................................................................................................ 12