6

USAGE

The machine is used for cutting metals and nonmetals. It's suitable to drill, mill

and widely use in the field for instrument, machining, repairing for cutting a single

part or a batch of parts.

II USE AND MAINTENANCE

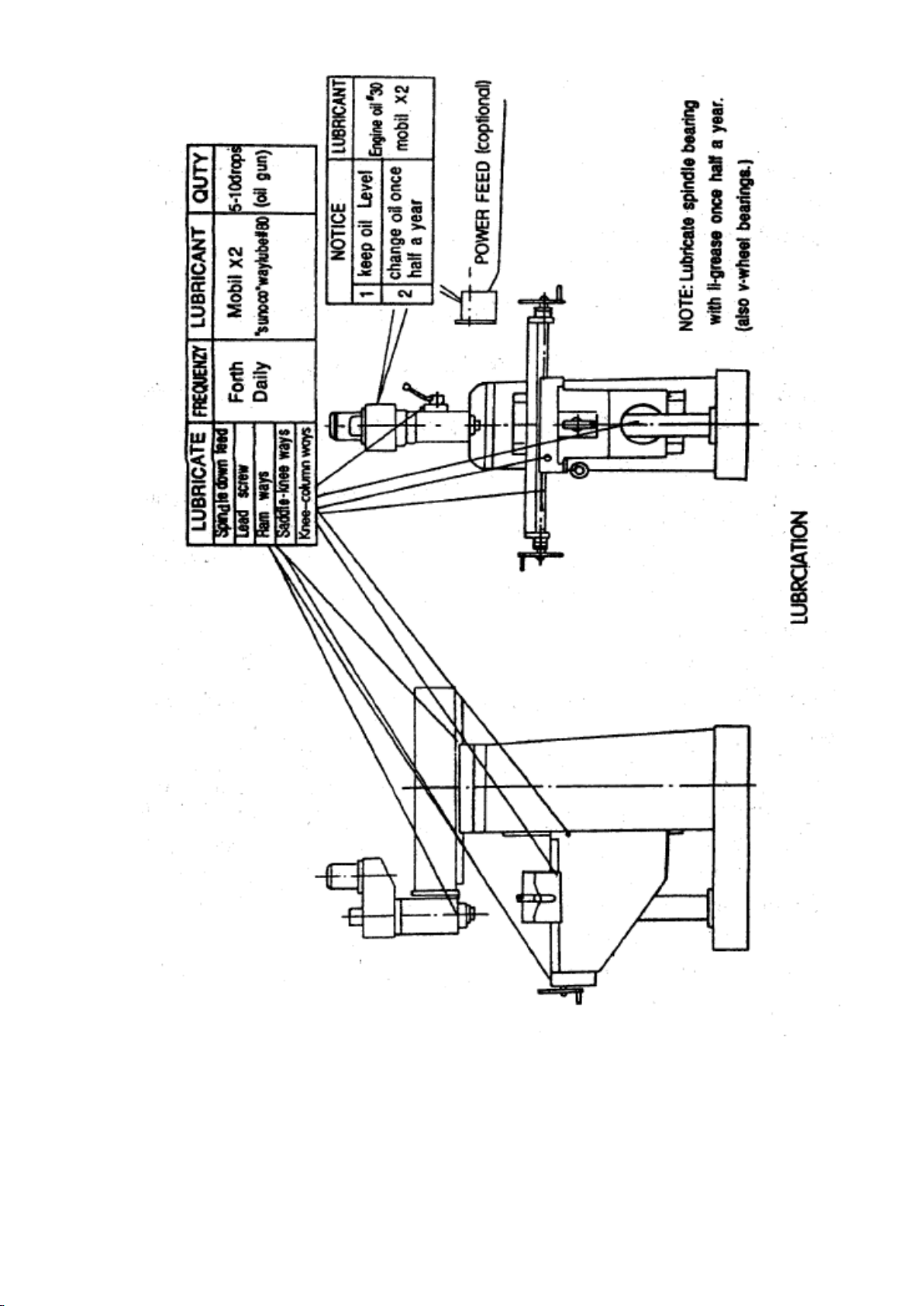

(Refer to chartg 1.)

1. The user must read the operation manual carefully, know structure and ability

of every handle, the system of transmission and lubrication well.

2. Before operating, inspect the normal conditions of the column lock handle, the

spindle sleeve and electric equipments. The ground line must be connect in the

ground.

3. When the position of spindle box to the working table need to be adjusted,

two clamping shaft ①locating on the right side of hoist--de-scend sliding must be

lossed firstly, then turn the hoist--descend handle in front of machine, to hoist or

descend the working table to the idea position, finally clamp the clamping shaft ①.

4. A micro--feeding institute is applied to the machine, before using, pls turn

locking bolt ③in right side to form the handle body with micro-feeding can be

realized. The spindle can revolve for tapping, through the universal switch equipped

on the left side of the head.

But if the power motor is single phase, such function can't be realized.

5. The handle body must be separated from micro-gear during drilling, when

drilling finished, loosen the handle ⑤, the sleeve will reset automatically. The elastic

force can be adjusted after loosing the screw locating in the bottom of spindle box