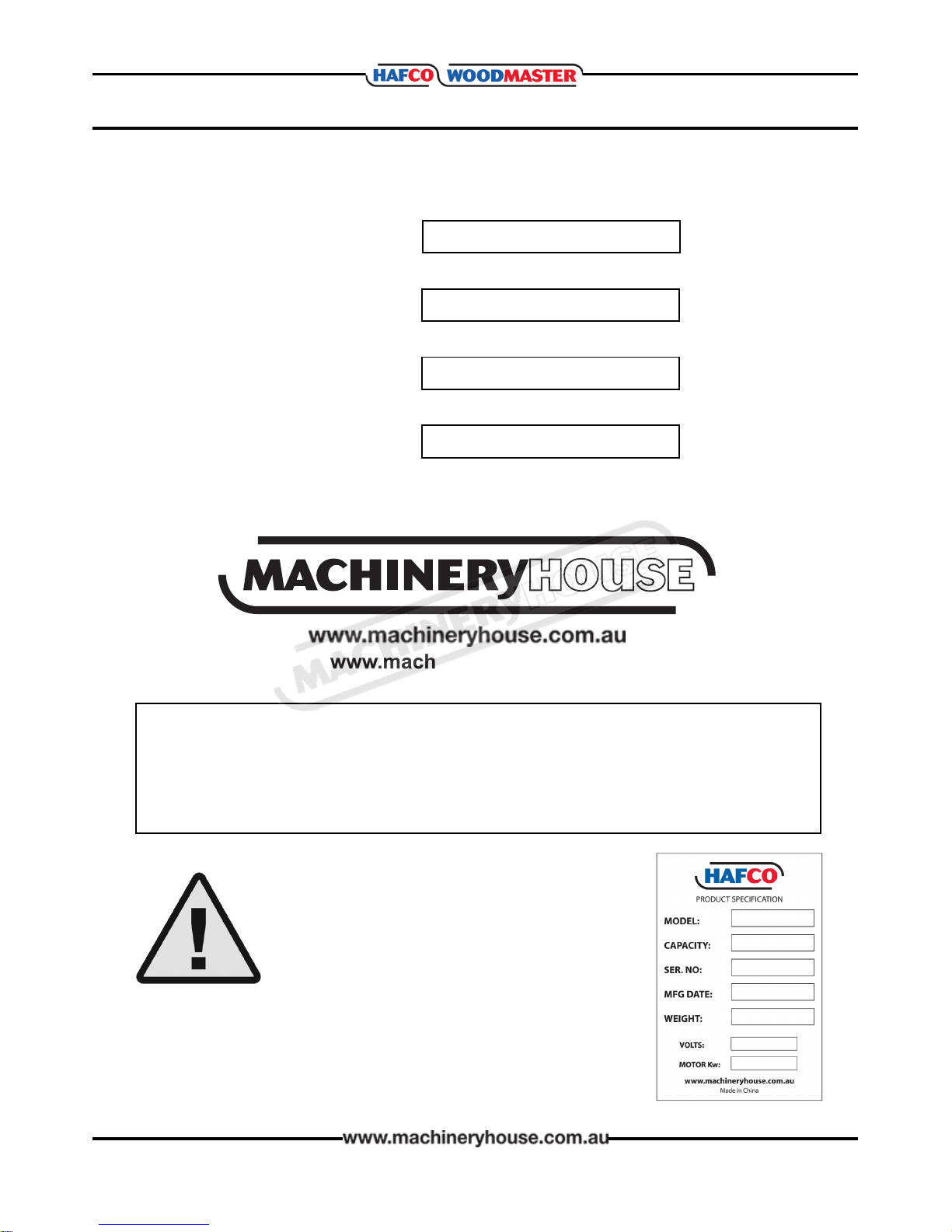

SPECIFICATIONS

Product Dimensions:

Weight................................................................................................................................................................. 43 kgs

Width (side-to-side) x Depth (front-to-back) x Height............................................ 852 x 270 x 442 mm

Footprint (Length x Width)........................................................................................................... 825 x 216 mm

Main Specications:

Swing Over Bed............................................................................................................................................ 356 mm

Swing Over Tool Rest Base........................................................................................................................ 286 mm

Distance Between Centers....................................................................................................................... 470 mm

Max. Distance Tool Rest to Spindle Center......................................................................................... 204 mm

No of Spindle Speeds.................................................................................................................................. Variable

Spindle Speed Range (2 Steps)....................................................................... 450 – 1800 & 900 - 3850 RPM

Electrical:

Power Requirement.................................................................................................. 240V, Single-Phase, 50 Hz

Full-Load Current Rating....................................................................................................................................... 6A

Minimum Circuit Size........................................................................................................................................... 10A

Switch Type..................................................................................................................... Electromagnetic Switch

Motors:

Type........................................................................................................................................ Universal Brush-Type

Power.................................................................................................................................................... 3/4 HP/550W

Phase....................................................................................................................................................... Single-Phase

Amps........................................................................................................................................................................... 6A

Speed............................................................................................................................................................. 1400 RPM

Power Transfer .......................................................................................................................................... Belt Drive

Bearings..................................................................................................... Shielded & Permanently Lubricated

Spindle Information:

Spindle Taper...................................................................................................................................................... MT#2

Spindle Thread Size....................................................................................................................... M30 x 3.5 Pitch

Spindle Thread Direction.................................................................................................................... Right Hand

Spindle Bore.................................................................................................................................................. 10.3 mm

Type of Included Spindle Center.................................................................................................................... Spur

Tool Rest Information:

Tool Rest Width..................................................................................................................................150 & 300 mm

Tool Rest Post Diameter............................................................................................................................ 25.4 mm

Tool Rest Post Length................................................................................................................................. 82.5mm

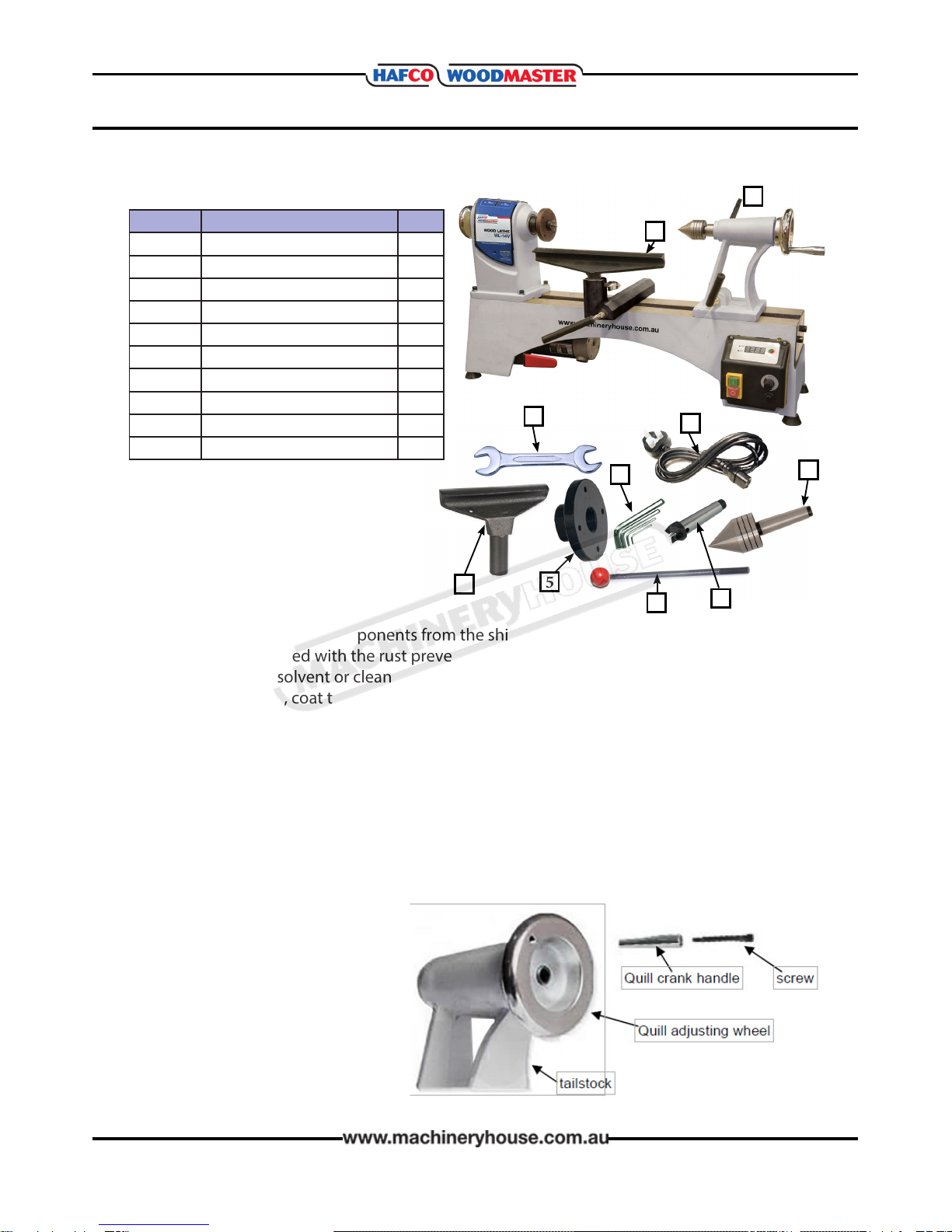

Tailstock Information

Tailstock Taper.................................................................................................................................................... MT#2