2

Please use the power outlet with ground wire in case of electric shock. If the power outlet is not

grounded, be sure to install the ground wire by professional technicians.

When using the battery to supply power, pay attention to the positive and negative electrodes of

the battery, do not reverse the connection. The safety of the storage area should be guaranteed

to avoid the short connection of the positive and negative electrodes of the battery.

If there is gas and other fl ammable gas leakage, it is necessary to close the gas leakage valve,

open doors and windows, ventilation and exhaust, do not plug in, unplug the transfer box,

otherwise it may cause explosion and fi re.

When unplugging the power plug from the power outlet, hold the power plug tightly instead of

pulling the wire of the power plug. If the wire is pulled by hand, it may cause electric shock or

fi re caused by short circuit; if the transport cooler is not running properly, unplug the power plug.

It is possible to cause electric shock or fi re by continuing operation in abnormal condition.

If the transport cooler is not running properly, unplug the power supply. It is possible to cause

electric shock or fi re by continuing operation in abnormal condition.

Before carrying out any maintenance or maintenance of the transport cooler, be sure to

disconnect the power supply of the transfer box in case of electric shock or injury.

Ensure that medicines or suspended particles inside and around the transport cooler are not

inhaled during maintenance. Otherwise, there is a risk of health hazards.

If the transport cooler is not in use for a long time, the power plug should be unplugged and the

backup battery switch should be turned off to prevent electric shock, leakage or fi re caused by

the aging of the power cord.

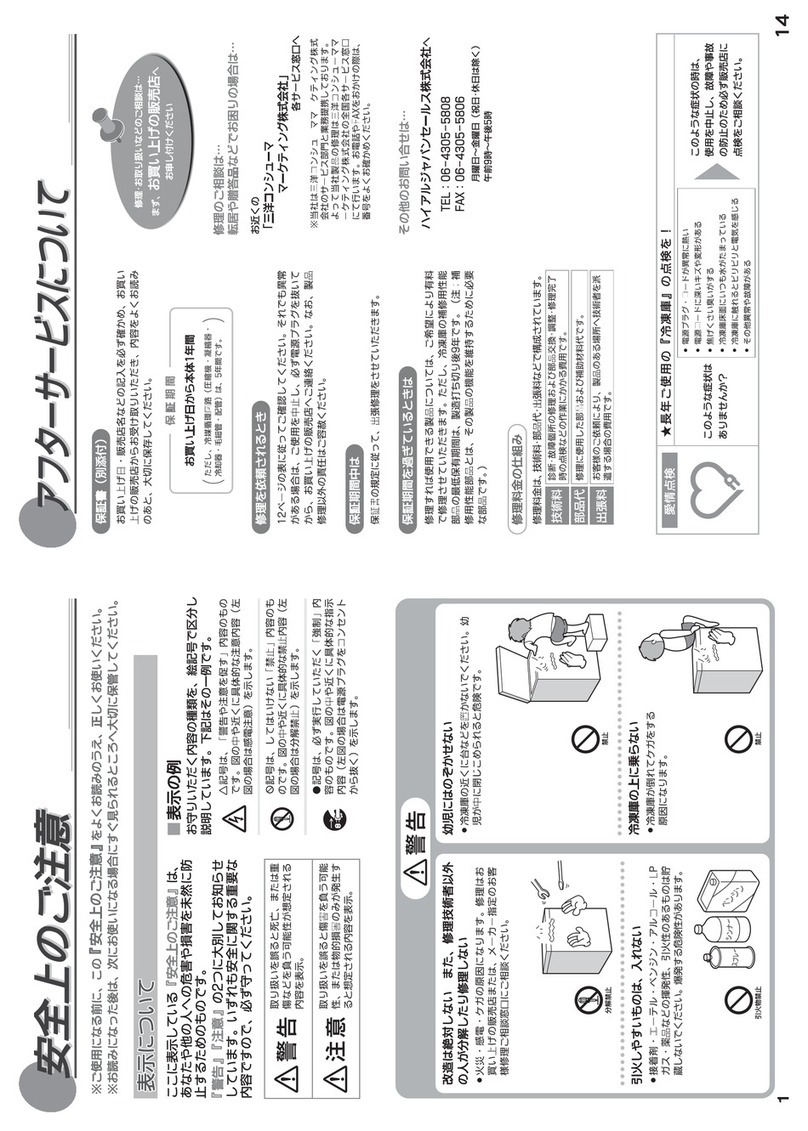

If the transport cooler is idle for a long time in an unsupervised area, ensure that the child does

not approach the transfer box and that the box door is not completely closed.

The Transport cooler scraps disposal by the corresponding personnel. Doors should be

removed to prevent accidents such as asphyxiation.

When restarting the transport cooler after power off, check the settings. Changes in settings

may result in changes in coming use.

Wear gloves when repairing, so as not to touch sharp edges or corners, causing injury.

When handling the transport cooler, care should be taken not to trip the transfer box, in case the

transfer box is damaged or personnel injured.

There should be no obstacles around the transfer box, keep ventilation unobstructed.

Tissue, material or liquid substances that are likely to burn or have a potential for explosion,

and the vapors they emit or fragments of explosives may release toxic substances that are not

usable.

The transport cooler shall not be placed in a wet place or in a place prone to splash water,

otherwise it will cause leakage or electric shock due to reduced insulation.

Water must not be dumped directly on the transfer box, otherwise it will cause electric shock or

short circuit.