D.R. ©2019 –HAIER EUROPE SERVICE ITALIA

Any change or alteration whatsoever of this document is formally prohibited except with the previous consent of the issuer.

Phase 1: Water is loaded to complete the "base level" of 6 liters, through the Detergent's

Compartment for Pre-wash (I).

Phase 2: 1 second pause.

Phase 3: The water heating element is fed for about 6 seconds (About 4.5A on the Digital

multimeter, if the element fitted will be 1600W).

Phase 4: The water load continues through the detergent's compartment for the Main Wash (II).

The Motor activates and then tumbles the drum clockwise at 55 rpm for about 16

seconds. If present, the Water Recycling System with Ejector is activated.

Phase 5: The Motor pauses for ~ 4 seconds. The water load continues as previously.

Phase 6: Simultaneously the Solenoid Valve fills through the washing compartment (II) and the

Motor tumbles the drum anticlockwise at 55 rpm, for around 12 seconds.

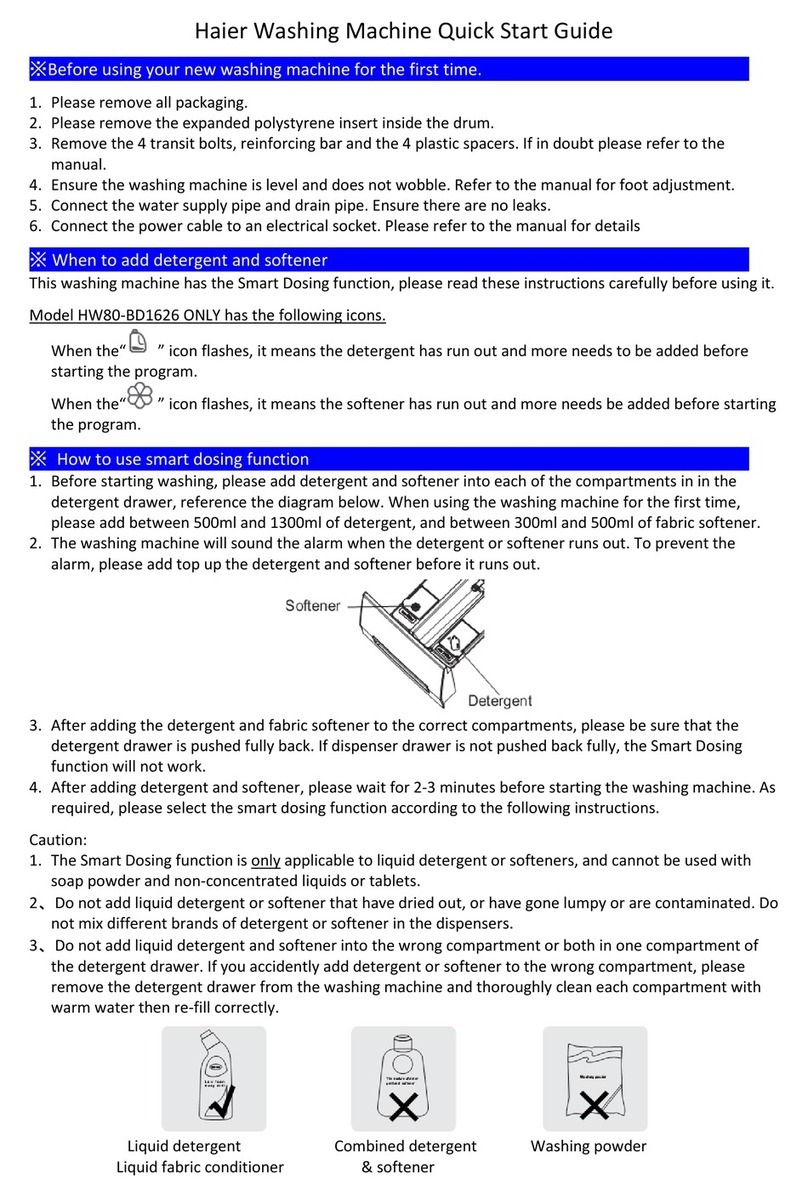

In the last seconds of this phase, the water load is carried out by the two solenoid valves

simultaneously feeding, to test the withdrawal from the softener bowl (See Picture 8 - ).

Phase 7:The Drain Pump is activated, until the pressostat reaches the "empty tank" condition.

Phase 8:A short spin is carried out, this lasts about 10 seconds, at half of the maximum speed

available without anti-balance. (The drum must be empty!)

Fase 9: While waiting for the door to open all the icons remain lit and the word "WAIT DOOR"

appears

END TEST WM:End of the WASHING MACHINE models test routine.

NB: only if the model in question is a washer dryer the following steps are also executed:

Phase 10:Immediately after the end of the spin phase, both the drying heater and the drying fan

with the condenser solenoid valve are active, the drying heater (for the first 5 seconds

- ~ 5.90A at 220-230V/CA) and the drying Fan and condenser solenoid valve for the

Steam Condensation (for a total of 15 seconds).

END TEST WD: End of the WASHER DRYER models test routine.

WHEN THE TEST ROUTINE PROCEDURE ENDS ALL THE SMART RING ICONS BLINK

SWITCH OFF THE MACHINE KEEP PRESSED THE ICON IN THE SMART RING CENTER FOR 3

SECONDS AND UNPLUG TO DISCONNECT THE WASHING MACHINE. LEAVE IT UNPLUGGED FOR

30”SECONDS AT LEAST.

This feature is used to make sure that the test routine procedure is completely reset and will

not be repeated when the washing machine is restarted.

Note: turn on the machine again and set the language the customer requires.

UK Engineers only: When connecting the washer for the test routine use your Energine meter

and test with your mulitmeter. You DO NOT need to use the Shuko patch cord.