2 / 47

Hakki Pilke 50 Pro Translation Version 1-2018

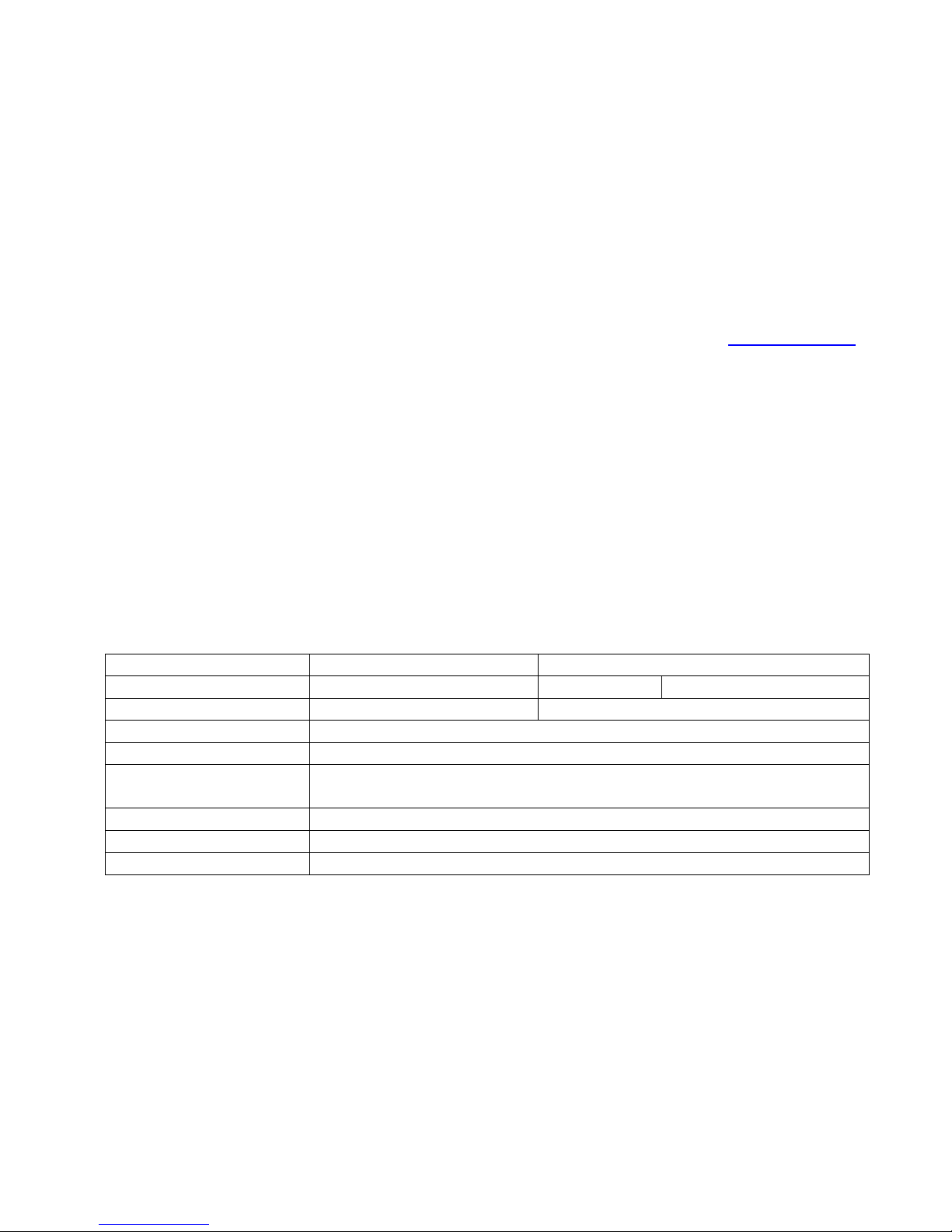

Table of contents

1. General information.................................................................................................................... 4

1.1. Introduction ...................................................................................................................................... 4

1.2. Purpose of use .................................................................................................................................. 4

1.3. Machine models and basic information ........................................................................................... 4

1.4. Operating conditions ........................................................................................................................ 4

1.5. Safety instructions ............................................................................................................................ 5

1.6. Noise and vibration........................................................................................................................... 5

1.7. Warning symbols .............................................................................................................................. 5

2. Receipt and assembly.................................................................................................................. 7

2.1. Delivery inspection ........................................................................................................................... 7

2.2. Lifting and moving the machine ....................................................................................................... 7

2.3. Main components of the machine ................................................................................................... 8

3. Control functions and setting up the machine............................................................................ 9

3.1. Arranging the machine for operation and transport........................................................................ 9

3.1.1. Placing the in-feed conveyor in the operating or transport position ....................................... 9

3.1.2. Placing the out-feed conveyor in the operating or transport position................................... 11

3.2. Controls........................................................................................................................................... 13

3.2.1. Tractor drive ............................................................................................................................ 15

3.2.2. Electrical drive ......................................................................................................................... 16

3.2.3. Adjusting the log length .......................................................................................................... 17

3.2.4. Using the out-feed conveyor................................................................................................... 18

3.2.5. Splitting blade adjustment ...................................................................................................... 19

3.2.6. Using a sawdust blower........................................................................................................... 19

4. Operating the machine.............................................................................................................. 21

4.1. Performing a test run on the machine ........................................................................................... 21

4.2. Placing logs on the in-feed conveyor.............................................................................................. 22

4.3. Feeding and sawing wood .............................................................................................................. 22

4.3.1. Hydraulic log press .................................................................................................................. 23

4.3.2. Jamming of the cutting blade.................................................................................................. 23

4.3.3. Sawing the last log................................................................................................................... 23

4.3.4. Using the quick couplings of the additional hydraulics........................................................... 24

4.3.5. Connecting a log table’s in-feed rollers to the in-feed conveyor............................................ 24

4.4. Log splitting..................................................................................................................................... 25

4.4.1. Jamming of wood on the splitting blade................................................................................. 25

4.4.2. Resplitting or splitting without cutting ................................................................................... 25