2 (29)

Hakki Pilke Eagle Translation Version 5

TABLE OF CONTENTS

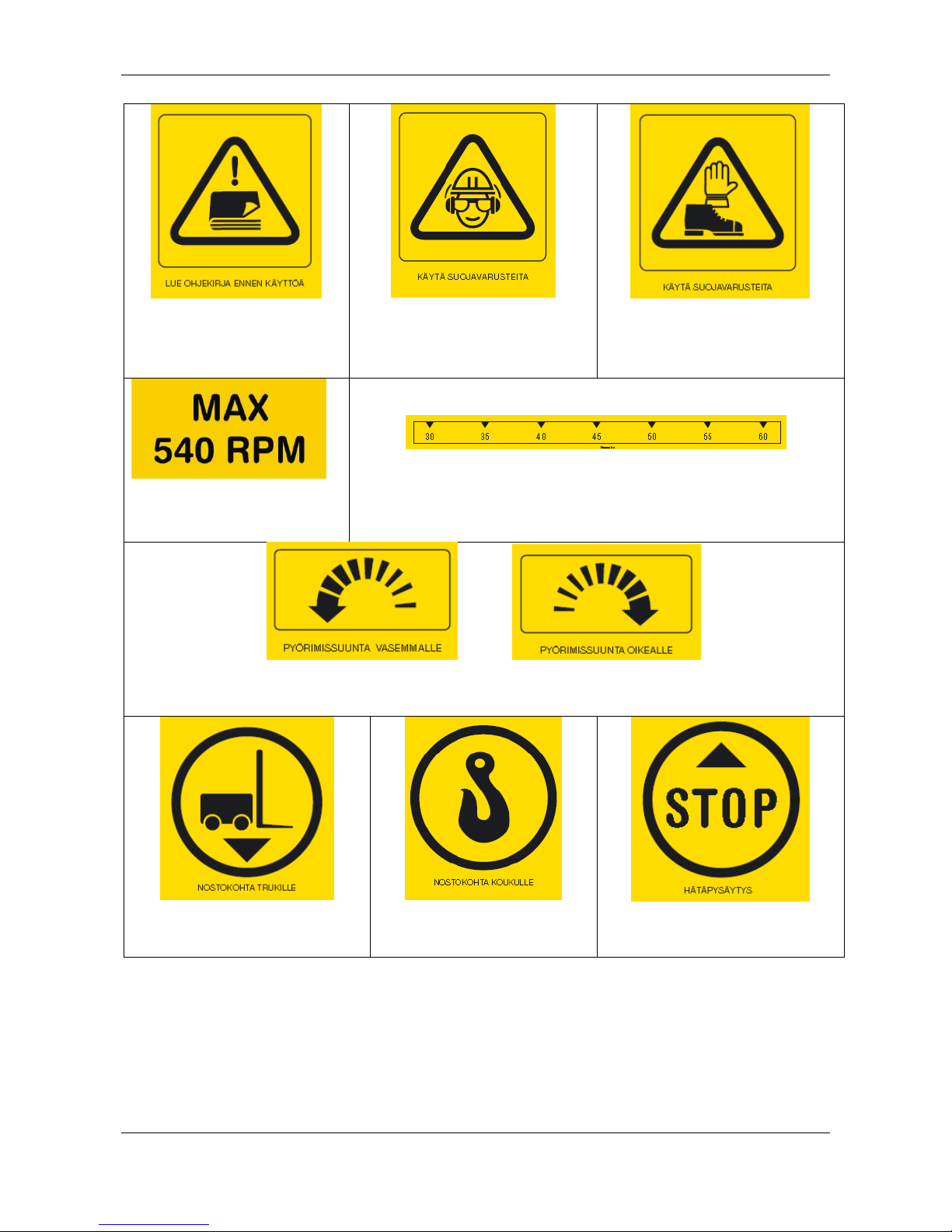

The machine carries following markings ...................................................................... 3

GENERAL SAFETY INSTRUCTIONS ...................................................................... 5

Commissioning a New Machine ................................................................................... 6

Installing the Cross-cut Cradle Extension..................................................................... 6

Adjusting the Cross-cut Cradle Inclination................................................................... 6

Adjusting the Splitting Table ........................................................................................ 7

Connecting the Machine to a Tractor............................................................................ 7

Electrically Driven Circular Saw with Splitting Device ............................................... 8

Start and Stop Buttons of the Electrically Driven Model ............................................. 9

Test Run....................................................................................................................... 10

Processing Firewood –General................................................................................... 11

Safety Precautions for Cutting: ................................................................................... 11

Processing Firewood ................................................................................................... 13

Splitting ....................................................................................................................... 14

EMERGENCY STOP Device ..................................................................................... 16

Removing a Log Stuck on the Splitting Cone............................................................. 18

Maintenance ................................................................................................................ 18

Sharpening the Saw Blade........................................................................................... 18

Blade setting ............................................................................................................ 19

Pre-stressing the Blade ................................................................................................ 19

Removing the Saw Blade ............................................................................................ 19

Installing the Saw Blade.............................................................................................. 21

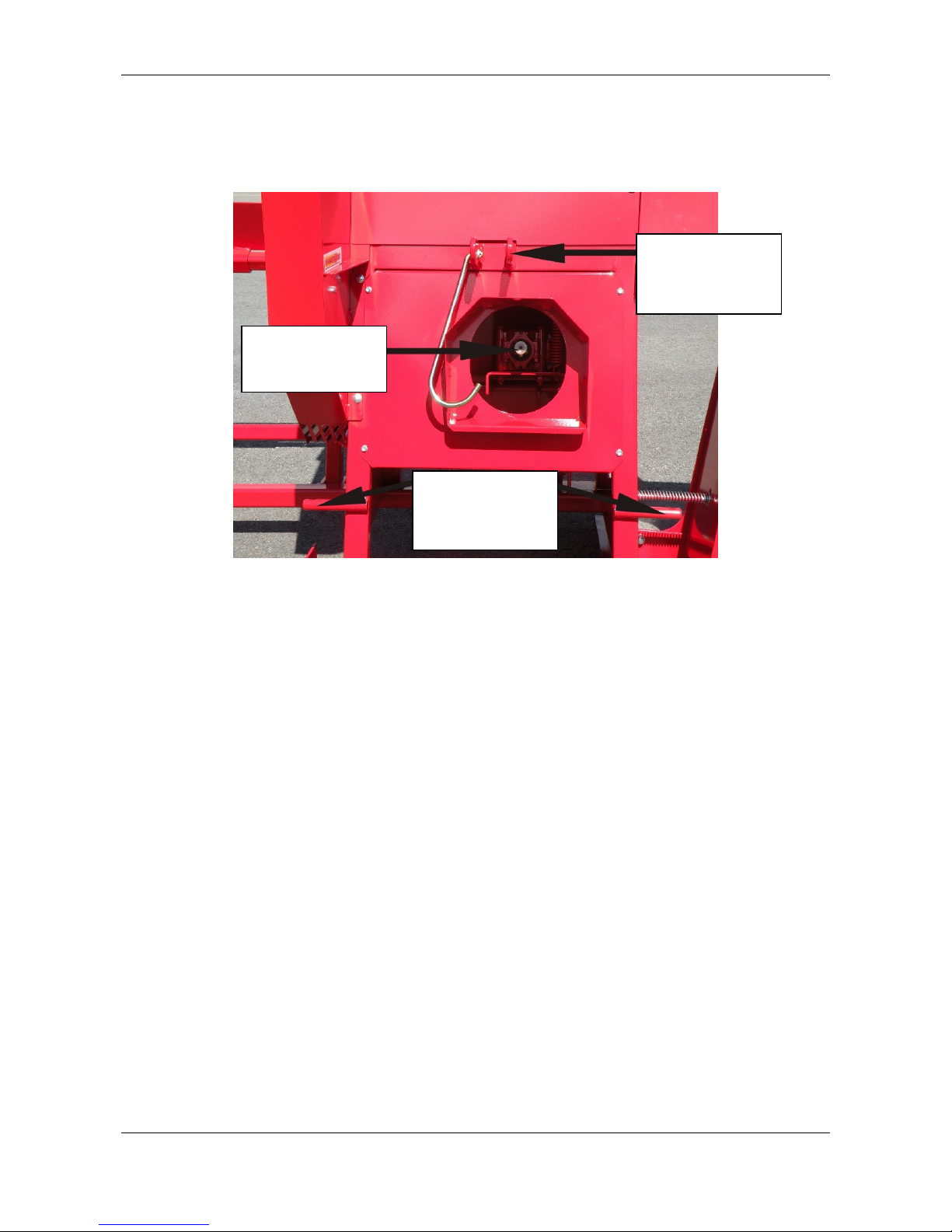

Adjusting the V-belts and emergency stop device...................................................... 22

Lubrication .................................................................................................................. 24

Transporting the Machine ........................................................................................... 24

Storing the Machine .................................................................................................... 24

Technical Specifications.............................................................................................. 26

Tractor-driven Circular Saw –Exploded View........................................................... 27

Tractor-driven Circular Saw –Part List...................................................................... 27

Emergency Stop Device .............................................................................................. 27

Emergency Stop Device –Spare Part List .................................................................. 27

Electrically Driven Circular Saw –Exploded View ................................................... 27

Electrically Driven Circular Saw –Spare Part List .................................................... 27

Transfer Wheels –Exploded View ............................................................................. 27

Spare Part List / Installing the Wheels on the Circular Saw ....................................... 27

EC Declaration of Conformity on the Machine .......................................................... 27

WARRANTY TERMS: .............................. Virhe. Kirjanmerkkiä ei ole määritetty.