Component Cause Action

Brake Drums Cracked or out of round Replace or check drum run out

Brake Shoes Shoe span out of spec Refer to OEM specs and replace if necessary

Uneven lining wear Check spider concentricity

Shoe pad missing Remove and replace shoes

Cracked shoes Remove and replace shoes

Camshaft Bushings Excessive movement Remove and replace cam bushings per OEM specs

Camshaft Flat spots on cam head Replace camshaft

Cracked/broken splines Replace camshaft

Worn bearing journals Replace camshaft

Chamber Bracket Broken/bent Replace bracket

Clevis Yoke and Pin Worn Remove and replace

Return Springs Broken/stretched or missing Remove and replace springs

Rollers Flat spots, grooved pin/worn Remove and replace roller and pin

Wrong size Remove and replace with correct parts

Spider Anchor Pins Grooved or scored/worn Replace spider or pins per OEM specs

NOTE: Long stroke chambers are identified with

square air ports or port bosses and special trapezoid

ID tags.

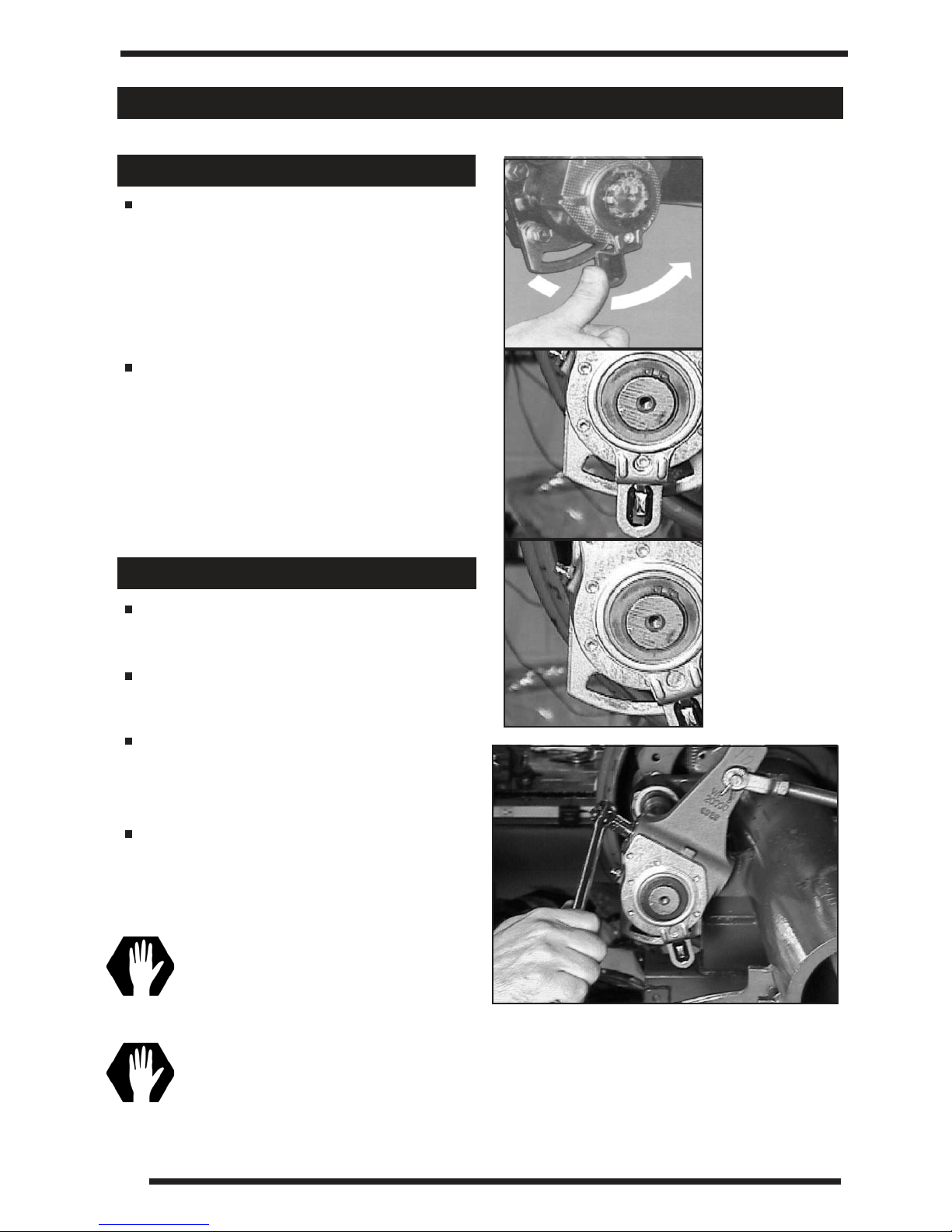

Measuring the Free Stroke

Free stroke is the amount of movement of the adjuster arm required to move the brake shoes

against the drum. With brakes released, measure from the face of the chamber to the center

of the clevis pin “A” (Figure 13). Use a lever to move the brake adjuster until the brake shoes

contact the drum “B” (Figure 13). The difference between the fully retracted and drum contact

measurement “B”–“A” (Figure 13), is the free stroke. The free stroke range should fall between

3/8”–3/4”.

Free Stroke Within The Range

If the free stroke is good, but the applied stroke is too long, there is probably a problem

with the foundation brake. Check the following and reference CVSA out-of-service criteria:

7

Foundation Brake Operational Check/Troubleshooting

Free Stroke

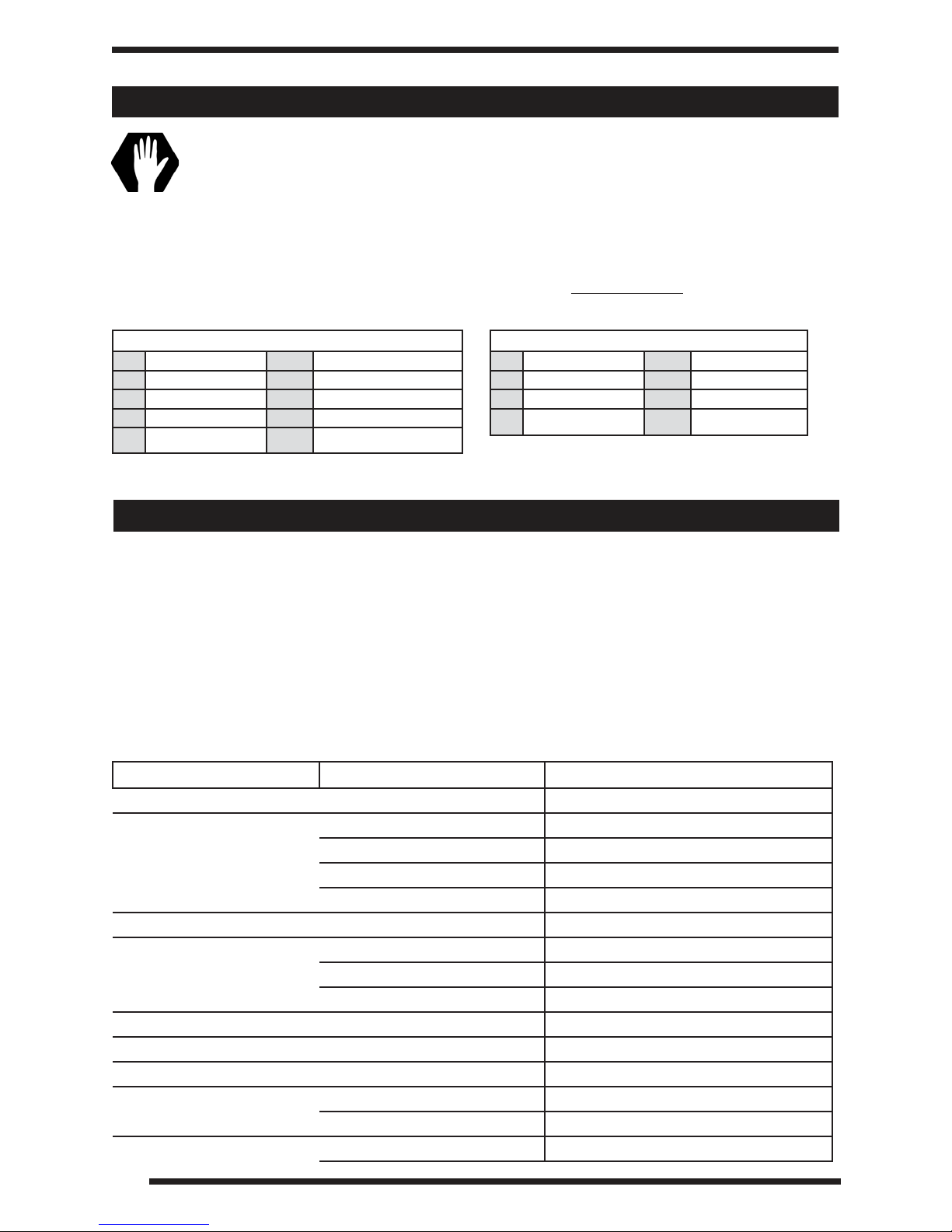

Standard Clamp Type Brake Chamber

Type Adjustment Limit Type Adjustment Limit

9 1-3/8” 24 1-3/4”

12 1-3/8” 30 2”

16 1-3/4” 36 2-1/4”

20 1-3/4”

Long Stroke Type Brake Chamber

Type Adjustment Limit Type Adjustment Limit

16L 2” 24LS 2-1/2”

20L 2” 30LS 2-1/2”

24L 2”

Note: Block wheels to prevent vehicle from rolling.

Ensure system reservoir pressure is at 90-100 psi.

Check that push rod is fully retracted; apply air to release spring brake.

North American Commercial Vehicle Safety Alliance (CVSA) Uniform Vehicle Inspection

Criteria: The applied stroke of the brake should be checked per CVSA guidelines at

90-100 psi reservoir pressure. Applied stroke should be at or less than the specified

readjustment limits as shown below.