Contents

Introduction

Nomenclature:

System

Familiarization/Features

and

Controls

..............................

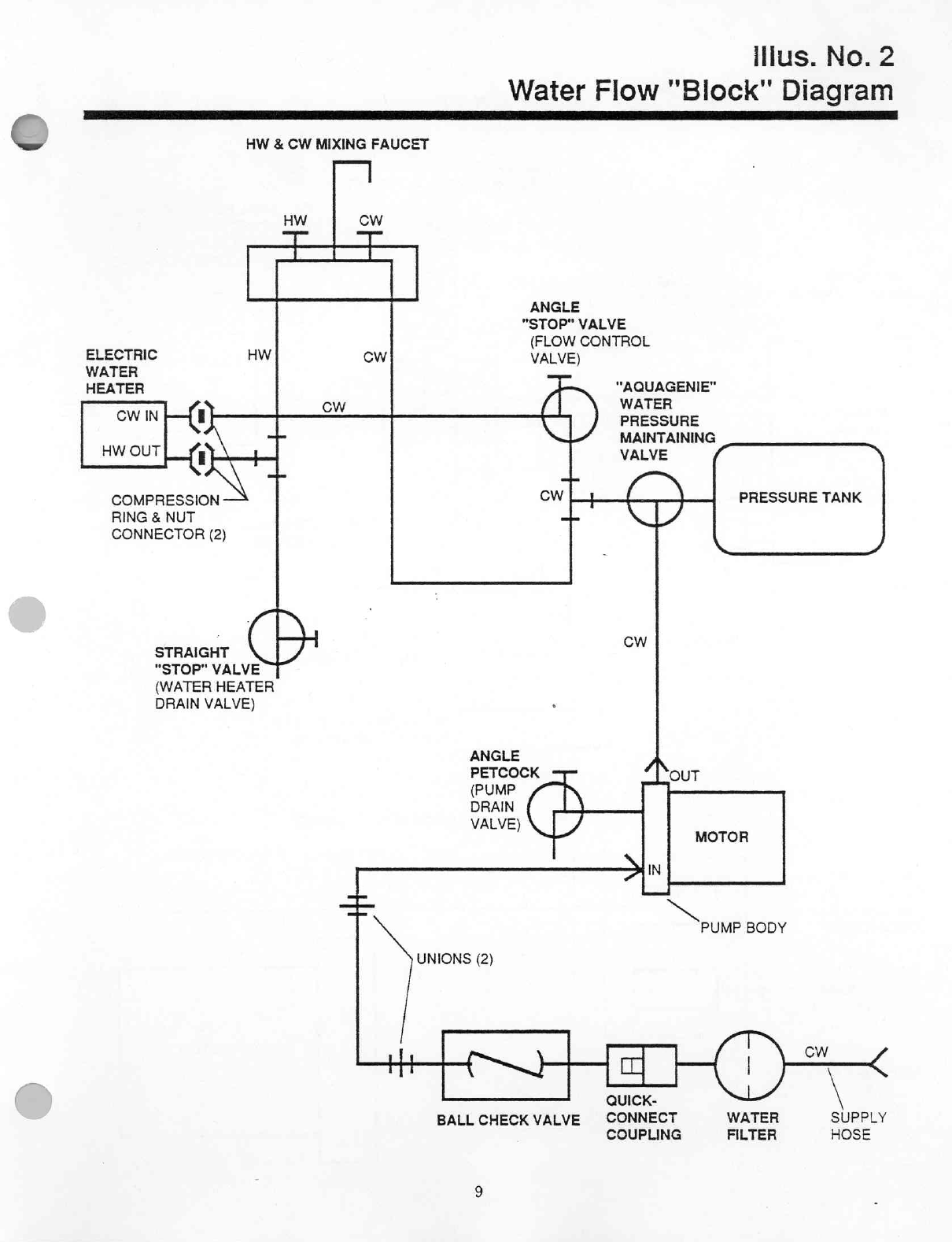

Water

Flow

"Block"

Diagram

............

nen

renerne

rn

rn

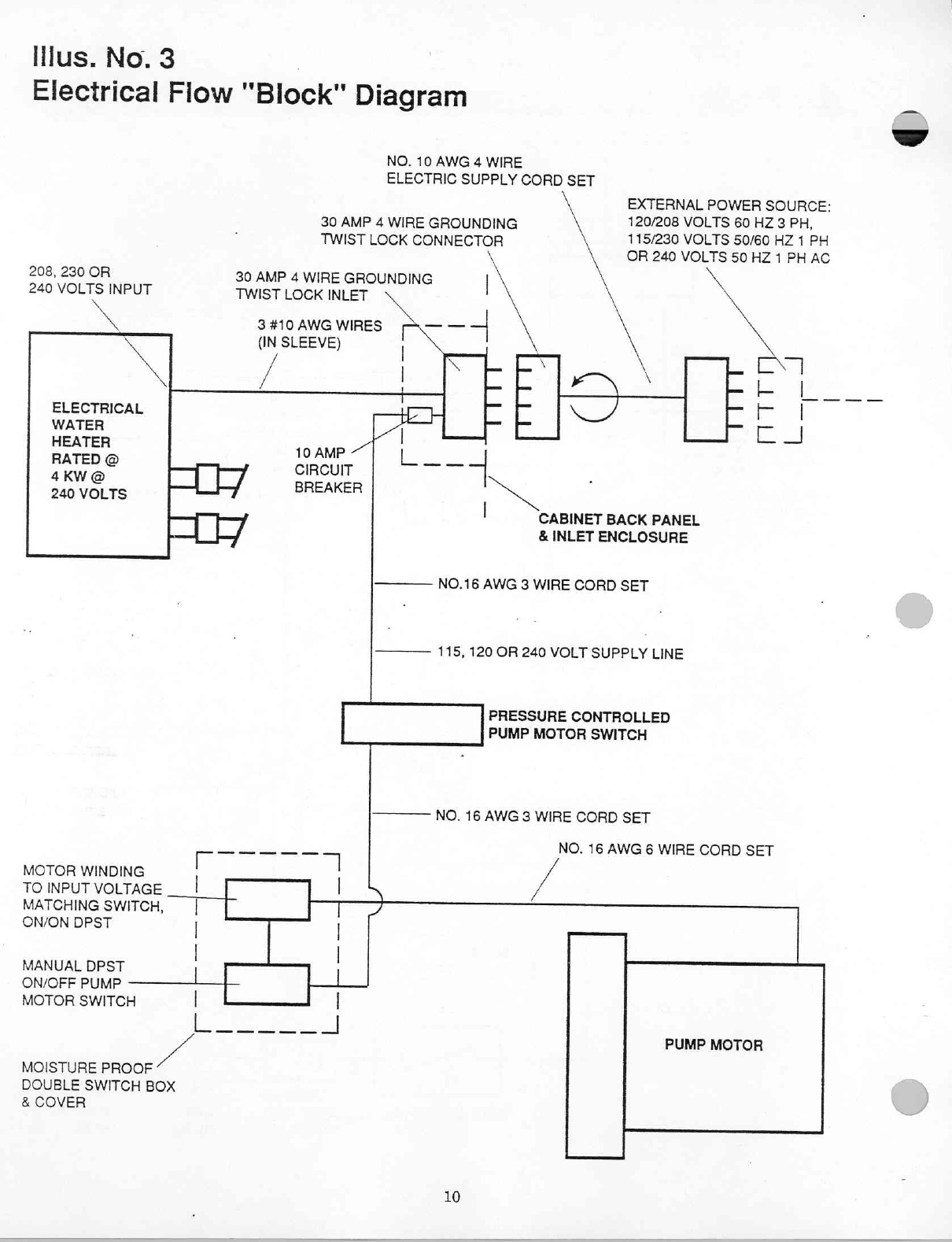

Electrical

Flow

"Block"

Diagram

ee

Patient:

Safety

and'Other

Precautions

mers

Equipment

Care

Installation

and

Operation

Instructions...

линии

seeren

dere

vsere

Electrical

Supply

Requirements

sise

Πο

ο

ο

ο

ο

ο

νο

Water

Drainage

System

and

Preparation

of

Unit

for

Storage

...........................

Storage

Requirements

Electrical

Schematic

-

Sink

Units:

120/208V,

3

Phase,

60

Hz...

120/240V,

1

Phase,

60

月

Ze

240V;

1

Phase.50

ssascsscsccpsczsnssciacitisssssecdsecerenenencnenseenensseraecngenenrsenneenenntenneess

Pictorial

WiringDiagram...........................

een

有

Troubleshooting

-

Super

Power

Pack.......

ra

Componentidentification-WaterHeater.................................................

Replacement

Parts

List

-

Water

Heater

i

ーー

Service

and

Disassembiy

-WaterHeater/Switches.............................................

Electrical

Schematic

-

Water

Heater

Only

oeeeee

eee

ce

Temperature/Flow

Chart

idee

MO

AAA

PümpMaiménance/TrOUDISSROO

NY...

cn

NE

Service

and

Disassembly

-

Pump

Special

Tool

and

ТезЕ

Едшриейи

.....................

линии

иена,

Parts

List

-

Pump

and

Motor

Assembly

ne

ene

eee

ne

nene

Service

and

Adjustments

-

Pressure

Tank

&

Pressure

Switch

................................

Parts'List

=

Sink

Unit

=-30"

Wide

ο

ου

iran

Parts

List

-

Switch,

Heater,

PUMP

ASSEMDIY

.................

ii

Design

Change

Notice

лесопарка

Consumable/Durable

Item

List...

LE

blender

11

12,

13,

14

12

12,

13,

14

14

15

16

17

18

19

20

21

22

23

23

24

25

26

27

27

28

29

30

-

31

32

-

33

34

35