CAUTION: DO NOT submerge the Valve Housing 7in water. Water will prevent

gas from freely passing through the housing into the Burner Assembly 5and

the flame may be erratic or extinguished and release gas into the room. Keep the

orifice of the Gas Nozzle =open and free of wax. If necessary, remove the Gas

Nozzle with 9/16” wrench, then clean it with hot water.

6.If Gas Odor Is Detected

See Figure 2 on previous page. An unlit Pilot Light 2can allow gas to accumulate in

the room when the unit is left with the gas supply turned on. If the Pilot Light fails to

stay lit, adjust it to a larger flame, or eliminate the draft blowing it out.

Leakage will result if the “O” Ring wis missing. Check to verify the “O” Ring is

installed if the leak occurs following cleaning or disassembly for other reasons.

If gas leakage is noted at the Gas Adjustment Thumbscrew 8or at the Gas Nozzle =,

gently tighten the parts with a wrench to snugly seal them against the body of the Valve

Housing 7. Do not over tighten, this may cause damage to the housing itself.

If leakage continues after securely tightening the Gas Nozzle =, or if the burner flame

fails to shut off automatically when ON-OFF Platform 9is released, return the Touch-

O-Matic®bunsen burner to Whip Mix for repair.

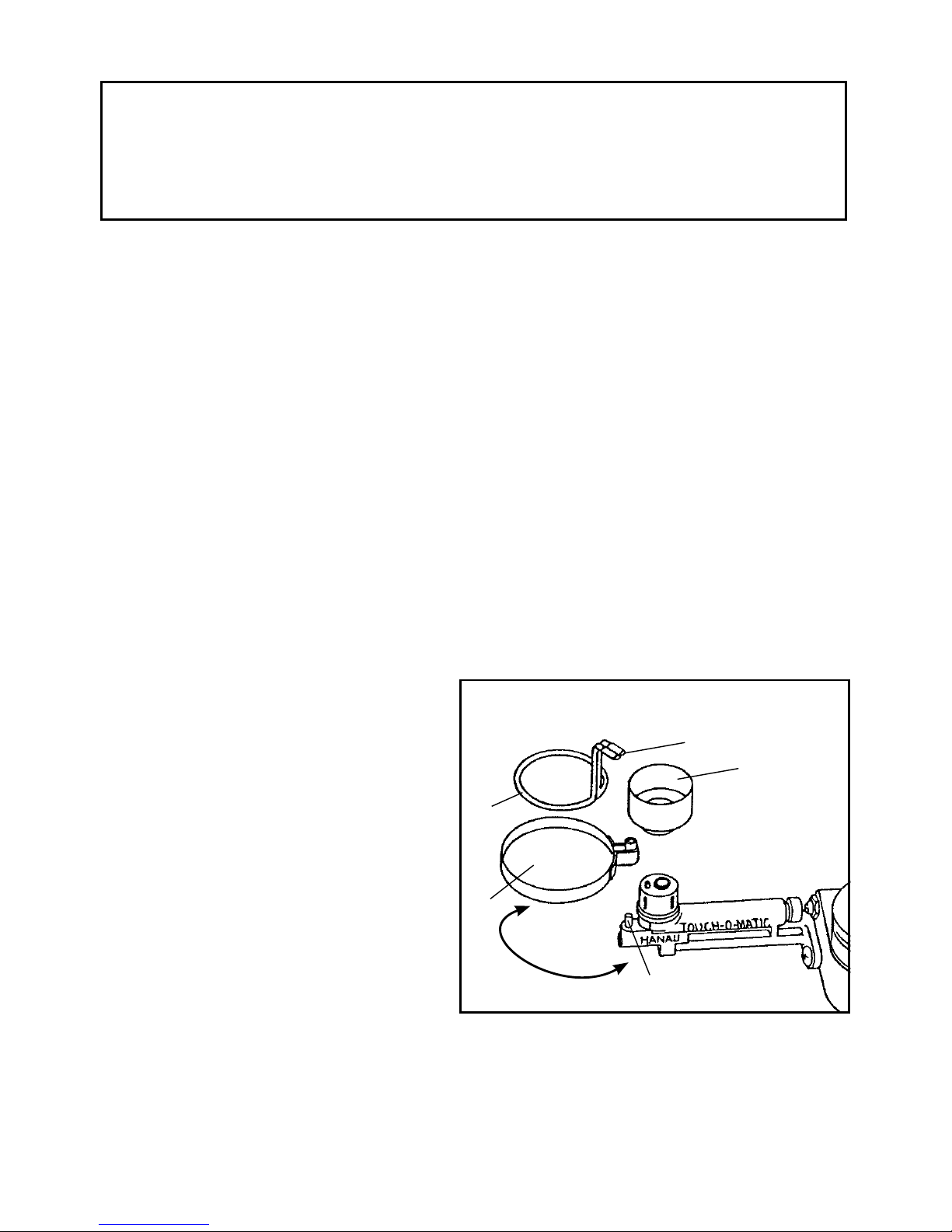

7. Use of Waxing Cup and

Loop Heat Conductor

The Waxing Cup tand the Loop Heat

Conductor yare optional accessories.

Remove the Pilot Shield 1and connect

the small loop built into the outer

circumference of the Waxing Cup over

the Post for the Waxing Cup 3. The

Loop Heat Conductor is placed into the

Waxing Cup, circular side down, and

the Loop Heat Conductor Stem uis

positioned above the Pilot Light, or main

burner, flame to transfer heat down into

the wax cup for softening and keeping

wax at a desired consistency. Replace

the Pilot Shield after attaching the

Waxing Cup.

8.Gas Conversion

Should you desire to operate your Touch-O-Matic®bunsen burner on a gas source

other than the one identified on the body of the Touch-O-Matic®burner and the

Gas Nozzle =, order and install a replacement nozzle. The Gas Nozzles available

1

y

t

3

u

Figure 3: Use of Waxing Cup

and Loop Heat Conductor

R

O

T

A

T

E