HANKISON Filter Monitor User manual

1

7610.718.14 4/02

FILTER

MONITOR

INSTRUCTION MANUAL

SERVICE DEPARTMENT: (724) 746-1100

Introduction

The Filter Monitor continuously monitors the differential

pressure (pressure drop) across a filter and alerts the

operator of the need for element replacement when

any of three operating criteria are met:

1. Maximum elapsed time (service interval) before

change-out - operator alerted when user selected

time period elapses.

2. Maximum allowable differential pressure - operator

alerted when user selected maximum differential

pressure occurs.

3. Intelligence - operator alerted when the optimum time

to replace the element(s) has occurred. The Monitor

calculates this using the element type, the initial charac-

teristic pressure drop and historical pressure drop data.

Grade 9 3 0.21 0.20 B

Grade 7 4 0.28 0.28 C

Grade 6 4 0.28 0.28 D

Grade 5 5 0.35 0.34 E

Grade 3 6 0.42 0.41 F

Grade 1 3 0.21 0.20 G

Recommended Settings for HF Series Filters

1. Maximum time before element replacement: Grades 9, 7, 6, 5, 3, - 12 MONTHS;

Grades 1 - 6 MONTHS;

2. Maximum pressure differential:

Programming Instructions

(Short version - for complete instructions see page 3)

1. To begin programming, press and hold ENTER button

for 3 seconds.

2. Press and hold the scroll button to input maximum

service interval (1 to 15 months) - press ENTER.

3. Press and hold the scroll button to select pressure unit

of measure (KG/CM2,PSI, or BAR). - press ENTER.

4. Press and hold the scroll button to input maximum

pressure drop (0.01 to 1.00 KG/CM2 or BAR; 0.1 to

15 PSI) Use Left Shift and Right Shift buttons to select

advance rate (e.g. by ones, tenths, or hundredths) -

press ENTER.

5. Press and hold the scroll button to select the element

letter type (see chart above) - press ENTER.

6. Select Initalize or Run mode.

Initalize - Scroll until initial pressure drop and run icons

are displayed. (To be selected during initial installation

and element charge out).

Run -Scroll until run icon only is displayed. (To be

selected if Monitor is reprogrammed without changing

the element).

7. Press ENTER to start program.

HF Series Setting Element

Grade psid kgf/cm2bar LetterType

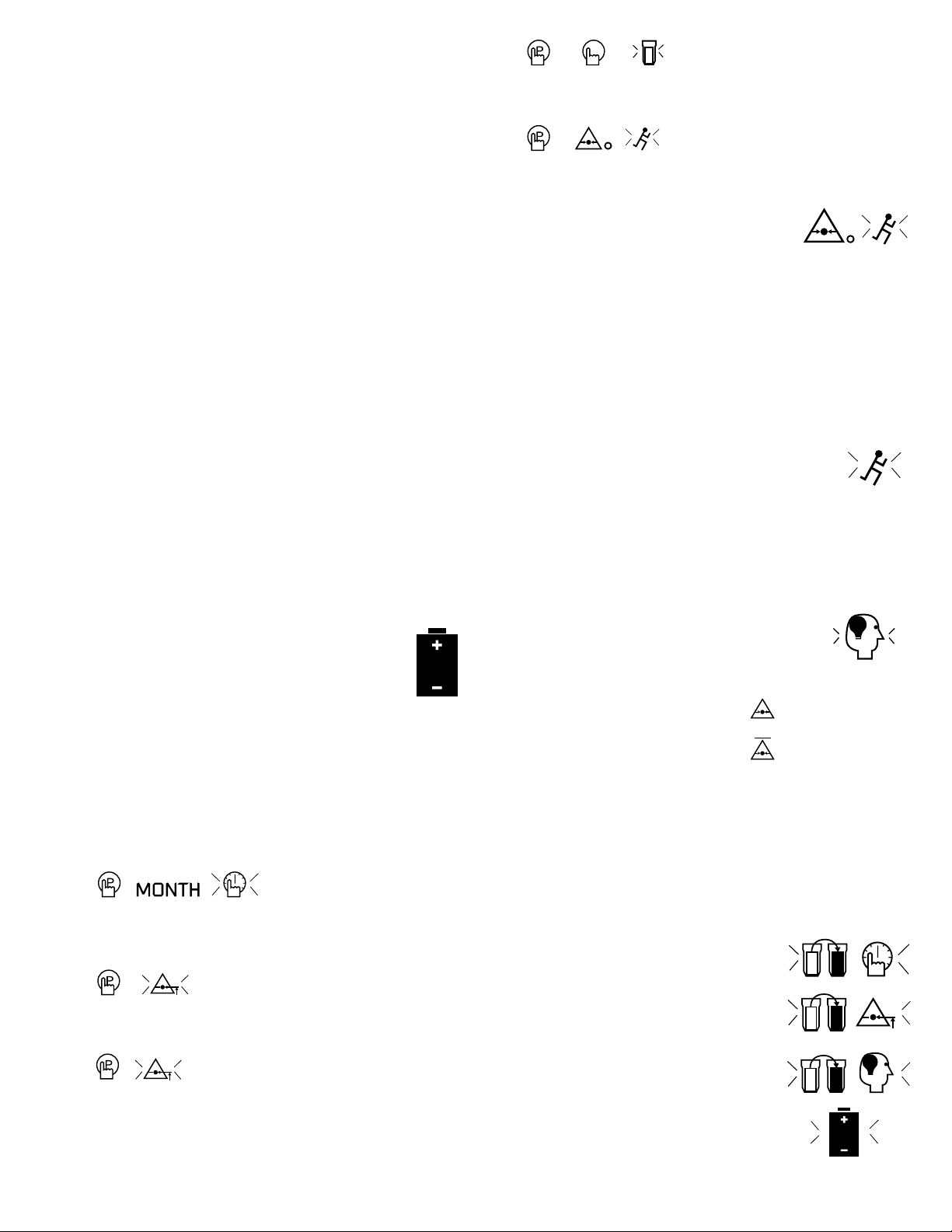

INITIAL P ICON

SHIFT LEFT

BUTTON SHIFT RIGHT

BUTTON

SCROLL

BUTTON

ENTER

BUTTON

OPERATOR

ALERT LIGHT

(RED LED)

LIQUID

CRYSTAL

DISPLAY

RUN ICON

1.0 INSTALLATION

1.1 Operating conditions

Maximum operating pressure: 250 psig, 17.6 kgf/cm2,

17.2 bar

Maximum compressed air temperature: 180°F, 82°C

Minimum/maximum ambient temperature: 10/130°F,

-12/54°C

1.2 Mounting

A. Changing orientation on units with Monitor

installed

1. Remove Monitor mounting screw.

2. Lift Monitor and turn 180°.

Note: Make certain that connector to mounting block is

not disconnected.

3. Reinstall Monitor to mounting block with mounting

screw.

B. Retro-fitting bowl/head type housings

Make certain filter is depressurized before disassembly.

1. Remove existing differential pressure devices or port

plugs if installed.

2. Install mounting block on filter head using o-rings,

gaskets and transmission bolts supplied with Monitor.

NOTE: Torque bolts to 30 inch-pounds (3.4 N-m). Do not

over tighten.

IMPORTANT: Mount block so that raised rectangle is next to

the INLET (high pressure or upstream) side of filter.

Note: Enlarge opening in cap if necessary. A pattern for a

larger cutout is located on underside of cap.

3. Connect lead from Monitor to prongs in mounting

block.

IMPORTANT: Position connector so that legs on connector

are on same side as raised rectangle.

4. Mount Monitor on mounting block using mounting

screw provided.

NOTE: Monitor may be rotated 180°so that it faces forward

with filter flowing from left-to-right or right-to-left.

C. Pressure vessel type housings

Make certain filter is depressurized before disassembly.

1. If mounting hardware has not been previously

installed, remove inlet/outlet port plugs and install

fittings, tubing, couplings, and brackets using parts

from Mounting Kit.

2. Connect mounting block to couplings using o-rings

and transmission bolts supplied with Monitor.

NOTE: Torque bolts to 30 inch-pounds (3.4 N-m). Do not

over tighten.

IMPORTANT: Mount block so that raised rectangle is next to

the INLET (high pressure or upstream side) connection.

3. Connect lead from filter monitor to prongs in

mounting block.

IMPORTANT: Connect so that legs on connector are on same

side as raised rectangle.

4. Mount Monitor on mounting block using mounting

screw provided.

2.0 OPERATION

2.1 Display Legend

LED DISPLAY

1. Unit of measure selection - pressure - pounds per

square inch.

2. Unit of measure selection - pressure - kilograms per

square centimeter.

3. Unit of measure selection - pressure - bar.

MONITOR

OPTIONAL

FILTER

BRACKET

LEAD

CAP

LEAD

MOUNT WITH LEGS FACING

RAISED RECTANGLE

MOUNT WITH

RAISED RECTANGLE

ON INLET SIDE

IN

OUT

O-RINGS

MOUNTING

BLOCK

TRANSMISSON

BOLTS

ENLARGE OPENING

IF NECESSARY

MOUNTING SCREW

LEG

LEG

GASKETS

LEAD

MOUNT WITH LEGS FACING

RAISED RECTANGLE

MOUNT WITH

RAISED RECTANGLE

ON INLET SIDE

LEG

MOUNT TO VESSEL

AS SHOWN

OR REMOTELY TO WALL.

IN OUT

SHIFT LEFT

BUTTON SHIFT RIGHT

BUTTON

SCROLL

BUTTON

ENTER

BUTTON

OPERATOR

ALERT LIGHT

(RED LED)

LIQUID

CRYSTAL

DISPLAY

1

234

567

9

101112131415

16

17

8

2

4. Indicates that predicted number of days until element

replacement required is being displayed or with 13 to

indicate element replacement required because maxi-

mum time has elapsed.

5. Displayed with 7 in program mode when inputting

maximum time before element replacement.

6. Indicates Monitor is in program mode.

7. Displayed in program mode when inputting maximum

time before element replacement.

8. Displayed in program mode with 10 when inputting

element type.

9. Displayed alone when Run mode selected or with 14 and

15 when Initialize mode selected.

10. Displayed in program mode with 8 when inputting

element type.

11. Displayed in program mode when inputting maximum

differential pressure or with 13 to indicate element

replacement required because maximum pressure

differential has occurred.

12. Indicates Monitor is processing data. Or with 13 to

indicate element replacement required due to intelli-

gence.

13. Indicates need for element replacement.

14. Indicates (displayed with 15) that initial characteristic

pressure drop is being displayed.

15. Indicates that current pressure drop is being displayed.

16. Indicates (displayed with 15) that average pressure drop

is being displayed.

17. Indicates need for battery replacement.

2.2 Batteries

A. Installation - Remove battery compartment cover

and install three AA, 1.5V batteries. Install in proper

orientation as noted in battery case. Re-install cover.

B. Life - Battery life is typically 15 months

operating the LCD display only with 7 days of

LED illumination thereafter. Red light will flash

and battery icon will show when batteries

require replacement.

C. Memory - Program settings and cumulative informa-

tion is retained during battery expiration and replace-

ment.

2.3 Programming

1. After batteries are installed, red LED light will glow

briefly; display will flash until unit is programmed.

2. Press and hold Enter button for 3 seconds to begin

programming.

3.

Select maximum elapsed time before element replace-

ment - press Scroll button to advance from 1 to 15

months.

4. Press Enter button to accept choice.

5.

Select unit of measure for pressure - use Scroll button

to choose between KG/CM2, PSI, or BAR

6. Press Enter button to accept choice.

7.

Select maximum allowable pressure drop - use Scroll

button to advance from 0.01 to 1.00 KG/CM2 or BAR; or

0.1 to 15 PSI. Use Shift buttons to change advance rate

(BAR and KG/CM2 -tenths or hundredths; PSI - tenths or

ones).

8. Press Enter button to accept choice.

9.

Input element type - use Scroll button to advance

from “A” to “H”. See chart on Page 1 for reference.

10. Press Enter button to accept choice.

11.

Select Initalize or Run modes.

Initialize

Use Initialize on initial start-up or after

replacing elements. To Select Initalize,

press Enter when pressure drop and

run Icons are displayed (Initialize symbol

shows). If Initalize is selected the program will ignore

the first 24 hours of operation to allow the element(s)

to achieve a steady state. After this period, pressure

drop measurements will be averaged over the next 144

hours to determine an initial characteristic pressure

drop. The differential pressure calculation used to

determine the optimum time for element replacement

uses this characteristic drop as the starting point.

After the initialization period, Monitor automatically

switches to the Run mode.

Run

To select Run, press Scroll button so that only

the run icon is displayed. If RUN is selected,

the monitor uses the previous initial charac-

teristic pressure drop as the reference. Use this mode if

the Monitor is re-programmed but the element is not

replaced.

12. Press Enter button to exit program mode and begin

operation.

2.4 Display

1. Run mode - in the run mode, Processing

icon flashes; indicating that the Monitor is

processing data.

2. Readouts - the display cycles through the following

readouts:

a. Current differential pressure.

b. Average differential pressure

over the past 24 hours.

c. Projected days until element replacement. When the

Monitor estimates that filter element replacement will

occur within 60 days, the days remaining will be

displayed. This allows time to have replacement

element(s) on hand.

3. Alarms

a. Indication of need for element replacement.

If any criteria for element replacement is met,

the red LED will flash.

1) Need for replacement based on

expiration of maximum time -

“0 days” displayed

2) Need for replacement based

on maximum pressure drop -

inputted maximum pressure

drop displayed.

3) Need for element replacement

based on intelligence (calculated

optimum time).

b. Need for battery replacement -

Battery Icon and red LED will flash.

3

4

WARRANTY

AUTHORIZATION FROM THE SERVICE DEPARTMENT IS NECESSARY BEFORE MATERIAL IS

RETURNED TO THE FACTORY OR IN-WARRANTY REPAIRS ARE MADE.

Division Of Hansen Inc.

Canonsburg, PA 15317-1700 U.S.A.

Tel 724-745-1555 Fax 724-745-6040

SERVICE DEPARTMENT: (724) 746-1100

The manufacturer warrants the product manufactured by it, when properly installed, operated, applied, and

maintained in accordance with procedures and recommendations outlined in manufacturer’s instruction manuals,

to be free from defects in material or workmanship for a period of one (1) year from date of shipment to the

buyer by the manufacturer or manufacturer’s authorized distributor provided such defect is discovered and

brought to the manufacturer’s attention within the aforesaid warranty period.

The manufacturer will repair or replace any product or part determined to be defective by the manufacturer

within the warranty period, provided such defect occurred in normal service and not as a result of misuse, abuse,

neglect or accident. Normal maintenance items requiring routine replacement are not warranted. The warranty

covers parts and labor for the warranty period unless otherwise specified. Repair or replacement shall be made at

the factory or the installation site, at the sole option of the manufacturer. Any service performed on the product

by anyone other than the manufacturer must first be authorized by the manufacturer.

Unauthorized service voids the warranty and any resulting charge or subsequent claim will not be paid. Products

repaired or replaced under warranty shall be warranted for the unexpired portion of the warranty applying to the

original product.

The foregoing is the exclusive remedy of any buyer of the manufacturer’s product. The maximum damages

liability of the manufacturer is the original purchase price of the product or part.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL, OR

STATUTORY, AND IS EXPRESSLY IN LIEU OF THE IMPLIED WARRANTY OF MERCHANTABILITY AND THE IMPLIED WAR-

RANTY OF FITNESS FOR A PARTICULAR PURPOSE. THE MANUFACTURER SHALL NOT BE LIABLE FOR LOSS OR DAMAGE

BY REASON OF STRICT LIABILITY IN TORT OR ITS NEGLIGENCE IN WHATEVER MANNER INCLUDING DESIGN, MANUFAC-

TURE OR INSPECTION OF THE EQUIPMENT OR ITS FAILURE TO DISCOVER, REPORT, REPAIR, OR MODIFY LATENT

DEFECTS INHERENT THEREIN.

THE MANUFACTURER, HIS REPRESENTATIVE OR DISTRIBUTOR SHALL NOT BE LIABLE FOR LOSS OF USE OF THE PRODUCT

OR OTHER INCIDENTAL OR CONSEQUENTIAL COSTS, EXPENSES, OR DAMAGES INCURRED BY THE BUYER, WHETHER

ARISING FROM BREACH OF WARRANTY , NEGLIGENCE OR STRICT LIABILITY IN TORT.

The manufacturer does not warrant any product, part, material, component, or accessory manufactured by

others and sold or supplied in connection with the sale of manufacturer’s products.

hankisonintl.com

Table of contents

Popular Water Dispenser manuals by other brands

Philips

Philips Pure Taste WP3961 Specification sheet

CSI

CSI CM24 Installation & operation manual

Thermaltake

Thermaltake Pacific RL240 user manual

HydrogenX

HydrogenX Hydro6000x instruction manual

Hellenbrand

Hellenbrand Economical Water Conditioning System WaterMate... Specifications

Elkay

Elkay DSBWCT5G Installation, care & use manual